Wohlers Associates, America Makes Offer 1-Day Design for Additive Manufacturing Course

Wohlers Associates and America Makes are partnering to offer a one-day design for additive manufacturing (DfAM) course for managers and executives on October 24, 2019.

Wohlers Associates and America Makes are partnering to offer a one-day design for additive manufacturing (DfAM) course for managers and executives on October 24, 2019. Following the success of previous DfAM courses conducted for engineers and designers on four continents, this course is the company’s first foray into educating management on wide ranging issues associated with DfAM. The course will follow the two-day members meeting and exchange held at America Makes’ headquarters in Youngstown, Ohio. The course is open to the public, with members of America Makes enjoying discounted pricing.

Course presentations, discussions and hands-on exercises cover the economics of AM, consolidating many parts into one, and topology optimization, which is letting mathematics decide where to place material to optimize the strength-to-weight ratio. The course also covers lattice/mesh structures, DfAM rules and guidelines, and distortion modeling and simulation. The course includes considerations for metal, polymer and composite materials, the creation of custom products, and reducing the need for expensive support material. Those attending the course will receive Wohlers Report 2019 at no additional cost. Details on the course are available at this web page.

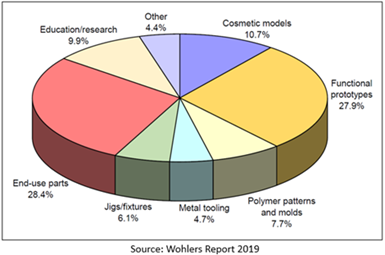

According to Wohlers Report 2019, the largest application of AM in 2018 is the production of end-use parts, as shown in the following chart. Jigs, fixtures and other forms of tooling — a combined 18.5% — represent an important range of applications that can save companies a tremendous amount of time and money. End-use parts and tooling rely heavily on designing in a way that optimizes for the AM process. Managers and executives considering the adoption of AM for production applications will gain an advantage over others if they attend this course.

Related Content

-

How to Supply Cooling to Additive Tooling

Additive tooling provides limitless options for cooling a mold’s difficult-to-cool areas.

-

MoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

-

A 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.