Pallet Changer Increases Productivity of Grinder by Improving Spindle Runtime

The CVG series vertical universal cylindrical grinding machine parts can be loaded onto a fixture outside of the machine while the machine is running.

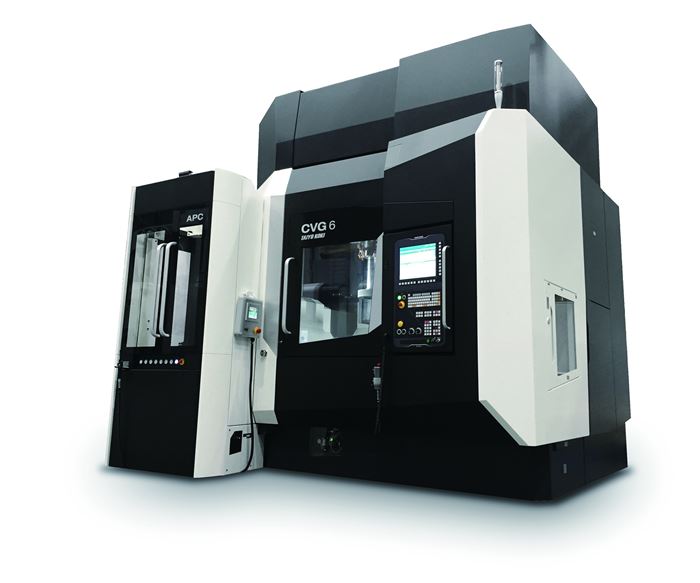

The CVG series vertical universal cylindrical grinding machine with an optional pallet changer from Taiyo Koki Grinding Machine Company, a DMG MORI company, is available in three different part-swing diameter sizes: 25.5", 37.5" and 53". The machine is able to grind OD/ID and faces all-in-one part chucking with guaranteed machine roundness accuracy of less than .00004". The machine has opposing twin wheel spindles. One is a larger, heavy-duty spindle dedicated to OD and face grinding that uses a 14" diameter wheel, and the other spindle is used primarily for ID and face grinding. Both grinding spindles are high-frequency.

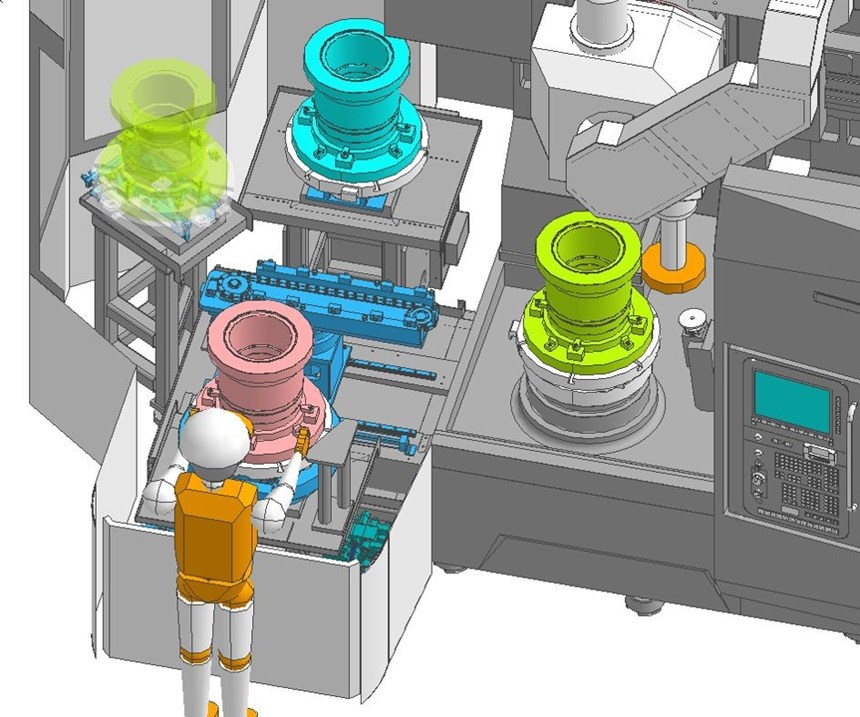

The optional pallet changer increases productivity by improving the spindle runtime. Parts can be loaded onto a fixture outside of the machine while the machine is running. Machinists can add an available part-clocking station with a dummy spindle, which enables parts to be rotated and “clocked-in” at the part-loading station. Machinists can run multiple jobs simultaneously by registering and setting different workpieces outside of the machine, which automatically selects programs and tooling for a different workpiece. Being able to run different jobs through the machine at the same time improves productivity and throughput.

Related Content

-

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

-

The Secrets to Hard Milling Success

The Secrets to Hard Milling Success

.jpg;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)

_970x250 1.png;maxWidth=970;quality=90)