NPE2018 Video Recap: Exhilaration, Innovation and Inspiration

MoldMaking Technology’s editorial team recaps some highlights from the show floor at NPE2018, including a technology slideshow, seven podcasts recorded live from the event and a video.

It is hard to believe that another NPE (National Plastics Exposition) has come and gone. Because this show is held every three years by the Plastics Industry Association, the buildup to it is almost like the buildup to Christmas. Everyone anticipates seeing, in action, cutting edge moldmaking and molding technologies, software, auxiliary equipment and machinery that will advance the plastics industry beyond expectations. It was here and gone in a flash, and we can say with complete honesty that this was one of the best NPE editions ever.

On the last day of NPE2018, we, the editors of MoldMaking Technology Magazine, sat down together to produce a fun wrap-up video about the show. (Stay tuned as we’ll be posting that video on our website and on social media soon, but see below sidebar for a related recap podcast!)

We agreed that it was almost overwhelming to cover because of the number of exhibitors rocking the Orange County Convention Center in Orlando, Florida. In fact, the Plastics Industry Association (PLASTICS) announced that NPE2018 was “the largest in history, with more than 2,180 exhibiting companies showcasing innovations in plastics in more than 1.2 million square feet of exhibit space on the tradeshow floor.” Exciting! What’s more, the MMT team, along with marketing and editorial staff from our sister publications Plastics Technology and Additive Manufacturing were the official news teams for the NPE2018 Show Daily newspaper. If you missed NPE or missed any of the five dailies, you can find them all here: http://npe.org/npe2018-show-daily.

What did we take away from the show? Following are some stand-out trends and technologies but be sure to also check out the slide show above for more highlights.

NPE2018 Highlights:

- Before even hitting the show floor, we scoured the “My Show Planner” app on the NPE website and we discovered that more than 67 North American mold manufacturing companies were exhibiting! We think this number must be double that of NPE2015. We were amazed at that number but more than that, we were impressed by the way they were marketing their services and by how many of them chose to collaborate with other exhibiting companies to further put their brand out there for all to see.

- There were many first-timers at NPE as well. They told us they were excited and overwhelmed at the size of the show and the technologies that were represented.

- Data, and the monitors and sensors that track it, was a main highlight of the show. Everywhere we walked, machines, molds, hot runner systems and more were displayed with monitoring technology—a step closer to realizing Industry 4.0 and the digital factory.

- The 3D/4D Printing Zone at NPE was abuzz with new opportunities to help customers speed products to market beyond using it just for conformal cooling. Many moldmakers were spotted in the zone, learning how they might integrate the technology into their operations to use for faster prototyping of products and even molds and mold components.

- Plastics Technology and Additive Manufacturing Media hosted the first 3D Printing Workshop during NPE and it was very well received. The workshop focused on 3D printing and additive manufacturing technologies from a plastics processing perspective. Topics included short-run production, conformal cooling, end-of-arm tooling, technology options, bridge tooling and material advancements.

- There was a lot of injection molding and blow molding going on at NPE2018 demonstrating new in-mold assembly and decoration technologies and more. At some booths the lines of attendees extended quite far as they waited to collect free giveaways including storage bins, watches, bottles of all shapes and sizes and more. We wondered how some of the items would ever get home with the attendees. The quantity and variety of plastics was incredible, plus the Plastics Industry Association, which hosts NPE, launched a new This is Plastics campaign and website where U.S. citizens can go to gather substantiated details about plastics, including what plastics are and how they are used; how plastics impacts the environment; how the plastics industry is working to ensure that plastics are safe; innovative uses of plastics; and the economic impact plastics has on our world.

Don’t forget to check out MMT’s Twitter feed because these highlights and many more from NPE2018 can be found there!

Related Content

Mold Repair, Design Solutions Serve Many Industries

NPE2024: Adler Industrial Solutions exhibits its selection of Pinnacle Molds and Rapid Mold solutions.

Read MoreOne-Stop Shop Simplifies Custom Surface Textures, Mold Performance

NPE 2024: Standex Engraving Mold-Tech specializes in managing every step of the project process, from texture design and engraving to preparing the tool for production.

Read MoreEducating the Next Generation of Plastics Professionals

These schools and local industry are working together to close the workforce gap in the plastics industry by offering hefty plastics curricula and training programs for degree-seeking students as well as current plastics employees looking to upskill.

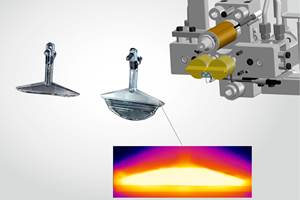

Read MoreLocalized Mold Temperature Control Reduces Knit Lines, Optimizes Melt Flow

NPE2024: Dynamic localized mold temperature control Heat-Inject Technology by Incoe Corp. demonstrates how the part surface quality and the filling of the cavity is optimized with relatively little effort using targeted heat pulses.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)