MoldMaking Technology Noteworthy News, Mar. 11, 2020

Read news from RJG, BIG KAISER Precision Tooling, and Wohlers Associates

RJG Germany Opens Injection Molding Training Facility

RJG Germany GmbH opened the doors to their new training lab on January 1, 2020.

RJG Germany GmbH opened the doors to their new training lab on January 1, 2020. The facility consists of a classroom that seats up to 20 students and a fully-equipped lab for hands-on experience.

The technical center currently consists of a 60-ton injection molding machine from Yizumi Germany GmbH, temperature control units and a material drying system from Moretto Deutschland GmbH. The lab is set up for a total of four injection molding machines. Courses that will be taught by RJG Germany are Systematic Molding, Decoupled Molding Workshop, Master Molder I (starting in Q4 2020), eDART Basic Training, eDART Advanced Workshop, CoPilot Basic Training and CoPilot Advanced Workshop.

RJG offers award-winning injection molding training around the world. The trainers are experts in the field who have first-hand experience with working on the plant floor. They know the challenges that often arise and how to conquer them. RJG training graduates are able to deliver substantial time and cost savings to their employers, whether it is through developing new products or managing existing projects.

“This new training facility will allow us to bring courses to Germany that were not previously possible,” said Frank Marschalek, business development manager at RJG Germany. “To our team, it’s an exciting new challenge and chance to share our knowledge with even more molding professionals. To our customers, it’s a new opportunity to further enhance their skills and progress their careers. We are proud of our facility and can’t wait to share it with the world.”

RJG has other training facilities around the world in the United Kingdom, France, China, Mexico and the United States. For more information, visit https://rjginc.com/training.

BIG KAISER Presents Fourth Annual Donation to National Robotics League

Customers and partners of Big Kaiser Precision Tooling teamed up to generate a $7,283 donation to benefit the National Robotics League (NRL).

Customers and partners of Big Kaiser Precision Tooling teamed up to generate a $7,283 donation to benefit the National Robotics League (NRL). The amount is nearly 10% more than last year and the fourth year-over-year increase in NRL funding from Big Kaiser.

The donation is a 2% match of all qualified orders from National Tooling & Machining Association (NTMA) and AMT member companies during the final two months of each calendar year. Manufacturers placed orders for cutting tools, tool holders, workholding and tool measurement systems, earning funds for the NRL at the same time.

“We need to get involved at every level to grow the next-generation workforce. Our company does that by partnering with local schools, our community colleges and the trade associations,” says Chris Kaiser, CEO of Big Kaiser. “NRL is just one more way for us to engage kids and promote careers in manufacturing.”

“We’re not just fighting a skills gap in our workforce, we have an ‘interest gap’ too. The NRL helps create excitement about manufacturing technology and STEM careers,” says Roger Atkins, president at NTMA. “We appreciate BIG KAISER’s continued support year over year, and of course all of the NTMA and AMT members who participate in the program to support the NRL.”

The National Robotics League is a manufacturing workforce development program of the National Tooling & Machining Association (NTMA) where students design and build remote controlled robots (bots) to face-off in a gladiator-style competition. Through the manufacturing process of Bot building, students’ imaginations are captured as they design, build and compete with their own robotic creations. Through this hands-on effort along with industry partnerships, students gain practical knowledge of Science, Technology, Engineering, and Math (STEM) – all essential skills for manufacturing. Learn more at www.GoNRL.org.

Amerimold Helps North American Molders, Mold Builders Win Work Via Reshoring

The Reshoring Initiative is co-sponsoring Amerimold 2020’s Sourcing Fair to connect North American molders and mold builders with buyers at major OEMs and upper tier suppliers.

The Reshoring Initiative is co-sponsoring Amerimold 2020’s Sourcing Fair to connect North American molders and mold builders with buyers at major OEMs and upper tier suppliers. The 25% mold tariffs and the coronavirus make this the right time for buyers and suppliers.

Registration is open for the 2020 edition, which will take place June 10-11 at the Suburban Collection Showplace in Novi, MI. Amerimold will connect more than 3,000 of the top owners, executives, and engineers involved in the complete lifecycle of the design, manufacture, maintenance and use of molds. The event includes an exhibit hall, a diverse collection of Amerimold Tech Talks, and various production sourcing events. Reshoring Initiative’s Founder and President, Harry Moser, is keynoting “Time to Rethink and Reshore the Manufacturing Supply Chain.”

The Amerimold Sourcing Fair, located directly on the show floor, is a one-of-a-kind event unique to Amerimold. It gives exhibitors and attendees an unmatched opportunity to better their business.

“Today, especially with the Tax Cuts and Jobs Act in effect and tariff and virus uncertainty, U.S. and foreign companies are reevaluating their sourcing and facility siting plans and considering increasing U.S. investment and shifting manufacturing to the United States. They are seeing the benefits of proximity, i.e. producing in the market, especially when the home market in the United States is still the world's largest,” says Moser.

Last year, Amerimold’s Sourcing Fair gave molders and mold builders the chance to connect with OEMs like Toyota, Otter Products, and Scholle IPN. Don Smith, Sr. Tooling Manager – North America, Scholle IPN says, “Participation in Amerimold’s premier Sourcing Fair provided national advertising that showcased the business as a global leader in flexible packaging. With multiple manufacturing facilities across North America, we are always looking to add support for our injection mold fleet who can manufacture “new” molds and maintain existing tooling for our core products. Amerimolds’s Sourcing Fair gave us a platform to visit with 16 world-class tool shops during the two-day event, several of which I am currently vetting. What an incredible time-saver in our search for tooling support.”

Moser adds, “The potential is huge. The timing is right. Reshoring Initiative user data suggests that about 30% of the $2.4 trillion of imports would come back if TCO (Total Cost of Ownership), instead of wage rates or purchase price, were consistently used to make sourcing decisions. Substituting domestic production for 30% of imports will increase domestic manufacturing by 30% and balance the trade deficit. The percentages are much higher with the special tariffs in place on Chinese products.”

SME Announces Insights on Additive Manufacturing for Investors

SME and the TCT Group, the producers of Rapid + TCT, North America’s largest and most influential additive manufacturing event, announce an exclusive dinner for investors at Rapid + TCT 2020, conducted by Wohlers Associates, Inc.

SME and the TCT Group, the producers of Rapid + TCT, North America’s largest and most influential additive manufacturing event, announced an exclusive dinner for investors at Rapid + TCT 2020, conducted by Wohlers Associates, Inc. The Wohlers Associates Investor Dinner sponsored by RAPID + TCT will give investors unique and valuable insight and perspective into the additive manufacturing (AM) and 3D printing market and industry.

The evening will begin with fine wine and cocktails, followed by a briefing from Terry Wohlers, principal consultant, president, and founder of Wohlers Associates. Also speaking are Brian Drab, research analyst and partner at William Blair & Company, and Arno Held, chief venture officer at AM Ventures. A special panel consisting of the following CEOs will provide commentary on strategies and the future of AM: Ellen Kullman, CEO of Carbon; Maxim Lobovsky, CEO of Formlabs; Ramon Pastor, head of 3D Printing and Digital Manufacturing, HP; and Ric Fulop, CEO of Desktop Metal.

“We at SME are thrilled to partner with Wohlers Associates to offer investors this exclusive opportunity,” said Maria Conrado, Rapid + TCT event manager at SME. “Connecting the investment community with the best thinking in the industry is core to our mission to serve the additive manufacturing community, and Terry Wohlers’ insights are invaluable to knowing where this industry is headed.”

“Getting sound information on AM and 3D printing is more important now than ever, considering the amount of money involved,” said Terry Wohlers. “Navigating the landscape and cutting through the noise created by so many new companies and products can be mind-numbing. Our company works hard to filter the chaff and deliver the gold so stakeholders can make the best possible decisions.”

Wohlers Associates has tracked nearly $1.5 billion in AM-related investments, resulting in unmatched insight. Much of it has come from information requested from hundreds of AM system and material producers, service providers, government agencies, researchers, and industry experts for publication in Wohlers Report 2020. Key findings from the new report will be shared at the Investor Dinner.

Those who attend the event will receive Wohlers Report 2020 as a part of the registration fee. It has served as the undisputed industry-leading report on AM for 24 consecutive years. "For those unfamiliar with this technology or looking for details on the players, markets, applications, and forecasts, I recommend the industry’s ‘bible’ from Wohlers Associates," stated Mark Mills, columnist for Forbes.

Details on the Investor Dinner are available at this web page.

BIG KAISER Offers New Chip Blower

Big Kaiser introduces a chip blower designed to make removing chips and coolant from parts and machine tables fast and easy.

Big Kaiser introduces a chip blower designed to make removing chips and coolant from parts and machine tables fast and easy.

The chip blower automates in-machine cleaning of coolant and chips by delivering high-volume air flow with spindle rotation. When not in use, the chip blower fits easily into any automatic tool change system for vertical, horizontal or multi-tasking machining centers. The chip blower can be used with automatic tool changers and programmed into a machining cycle, helping to improve machine utilization and increase productivity. The chip blower complements the solid construction, fixed blade chip fan that was introduced two years ago.

The chip blower is available in three different sizes all with center-through coolant for high-pressure washing. To learn more about the chip blower, visit https://www.bigkaiser.com/en/products/product-accessories/cleaners/chip-blower.

Related Content

MMT Chats: Applying Bench Lessons to the Business of Moldmaking

For this MMT Chat, my guest is Mark Gauvain, one of MMT’s newer Editorial Advisory Board members who has plenty to share as he recently made the move from working for some big manufacturers to working for himself as a consultant to moldmakers and molders on procurement and technology investment strategies.

Read MoreSybridge Technologies' Operations Manager Shares Three Favorite Articles: Purchasing, Transfer Tooling, Scientific Molding

MMT's Editorial Advisory Board shares its top MoldMaking Technology articles of all time and how this content has been valuable to their businesses.

Read MoreMore Than 60 U.S. Mold Manufacturers Rally to Keep China Tariffs

Out of the 358 comments submitted to maintain the Section 301 tariffs on China, 20% were mold and die makers answering AMBA’s call-to-action.

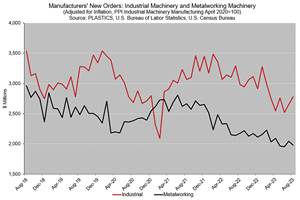

Read MoreResilience and Reflections: Moldmaking in the Evolving Economic Landscape

As moldmakers navigate this complex year marked by fluctuating business activities, and approach the upcoming year with cautious optimism, three key considerations should guide their decisions.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)