Case Study / Software, Energy/Power Generation, Defense

CAM Capabilities Give Hi-Tech Mold & Tool an Edge on Engineering Resin Components

#casestudy

Computer aided manufacturing (CAM) is a well-known discipline in the realm of injection mold building, where it provides numerous productivity advantages for engineers and toolmakers, both in terms of making CNC manufacturing equipment more productive, and shortening the leadtime for the delivery of prototype molds and parts. However, once the mold is in production molding shops generally don't have much use for CAM, but that could be changing.

Hi-Tech Mold & Tool, Inc. (Pittsfield, MA) has integrated CAM with its injection molding operations to deliver high-precision parts molded from engineering resins to aerospace, medical and green technology customers. The goal of these post-machining operations is to assure a level of precision that is unattainable by molding alone, due to the uncertainty of shrinkage factors. The company is using this process to deliver high-precision parts and components from such high-end engineered materials as PEEK, glass-filled PEEK, glass-filled polysulfone and Meldin®.

Early Adopter

Hi-Tech Mold & Tool is a full-service custom injection molder, providing a complete range of plastic and silicone processing services to OEMs worldwide. Hi-Tech specializes in metal to plastic conversions and serves such markets as military, aerospace, telecommunications and medical components.

Carleen Matthews, Vice President of Hi-Tech Mold & Tool says “We have taken an aggressive position in the high-tech molding marketplace by being willing to adopt technologies that many other molders have been reluctant to consider. For example, we have been molding extreme high-temperature materials for a number of years now. Post-machining operations are a perfect complement to those capabilities. Our comfort with engineering resins and their processing requirements has resulted in a number of manufacturers seeking our help in launching products with advanced design concepts that rely on these materials.”

Featured Content

The company formally launched its post-machining capabilities within its Secondary Operations Department early in 2010. This involved hiring Steve Carr as a full-time CAM programmer and CNC machine operator. Carr was immediately asked to participate in the evaluation and selection of a versatile and efficient CAM software package for post-machining. This software would be used to program the company’s Fadal 4-axis mill and Prototek rapid prototyping systems.

CAM software selection was considered to be a critical task, since post-machining would be performed on products made from very expensive materials. Scrapping a single part could result in the loss of thousands of dollars.

After evaluating a number of competitive products, the company selected Mastercam Mill (from CNC Software, Inc.). Mastercam is the most widely used CAM software for manufacturing, and packages are available for a wide range of CNC systems and machining applications. CAM was immediately integrated into the day-to-day workflow of Hi-Tech's Secondary Operations Department. It was also immediately put to use in the manufacturing of prototypes for some advanced parts incorporating high-temperature materials.

Bolstering Air Vessel Integrity: Hi-Tech is currently in production of custom molded carbon-filled PEEK pressure vessels that are used in systems that control cabin pressure in commercial aircraft. Compared to welded aluminum and steel vessels, the PEEK components are lower in weight, comparable in pressure containment (up to 2,500 lbs. in this case) and have no seams that could become compromised and allow air to escape.

Tolerances on this component are very tight and it would be impossible to arrive at the final specifications through molding alone. Numerous post-machining operations are performed on this component, including milling, drilling, tapping and surface machining (to meet flatness specifications).

Squelching Down-Hole Cross Talk: The integrity of the electronic signals in down-hole electronics is of absolute importance. To eliminate the prospect of cross talk between connectors used in deep-water oil exploration, Hi-Tech has been contracted to overmold them with PEEK, which has superior electrical insulation properties.

The connectors have unique contours and they must fit into very confined spaces. There would be no way to manufacture them consistently to the close tolerances required without post-machining. In this application, the precision contouring capabilities of Mastercam are particularly important.

Lightweight Power Re-generator: Meldin® is a proprietary high-temperature polyamide material that is particularly useful for manufacturing specialized machinery components. Its unique combination of properties includes a temperature range from cryogenic to intermittent use at up to 900°F, self lubrication, and superior rigidity and strength.

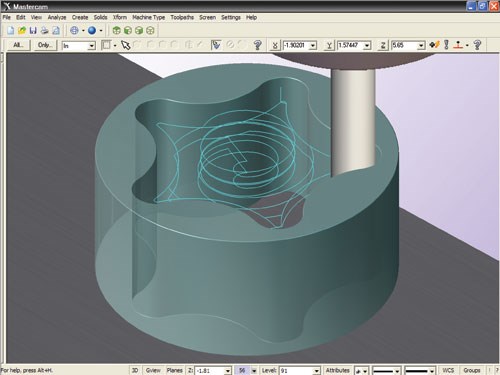

Hi-Tech is currently working with this material to manufacture a high-speed rotor used in a power regeneration system for military vehicles. The part that rotates ultra-high RPMs is part of a system that converts mechanical energy from the vehicle’s shock absorbers into fluid power. Important characteristics of the material for this application are its lightweight for precise control of the rotor and a tight molecular structure that resists chipping and abrasion over long periods of severe use. The precise geometry of the part and .002" tolerances for precise clearance demand post-machining.

The prototype rotors are milled directly from blocks of Meldin. At a material cost of hundreds of dollars per pound, this is a very expensive approach. Once the final design has been approved, Hi-Tech is hoping to mold the parts to near net shape and then machine them. This will dramatically reduce the cost of Meldin scrap.

CAM Combats Costs

Before Mastercam was installed, Steve Carr generated CNC toolpaths for post-molding machining operations by writing code manually. With Mastercam, what used to take days can now be accomplished in an hour or two. This has allowed a single programmer/machine operator to keep pace with machining requirements in a fast-growing secondary operations department, while reducing leadtimes for prototyping.

Because the raw materials are so expensive and so much value has been added to the parts when they arrive at post-machining, Hi-Tech has devised a number of CAM-based strategies to reduce costs. Making machined prototypes prior to sign-off on the final designs has helped customers reduce tooling costs. Once tools have been approved, molding the parts as close as possible to their final shape prior to post-machining minimizes the generation of scrap from materials that cost upwards of $50 per pound.

Computer simulation features in Mastercam (Backplot and Verify) are used to ascertain that toolpaths are safe to run without fear of crashes that could damage equipment, tooling and parts. They also verify that programs will remove no more or less than the appropriate amount of material. Computer simulation is also used to determine machining cycle times for more precise quotes and tighter scheduling of secondary operations.

Future Targets

In 2011, Hi-Tech Mold & Tool will be aggressively targeting its goal of specialized services to the medical components manufacturing industry. This will begin early in the year when the company expects to be ready for ISO-certification for medical component assembly.

Later in the year, Hi-Tech will open a new plant, dedicated to cleanroom manufacturing, primarily for medical components. Manufacturing medical components from high-temperature engineering resins, and post-machining them will ensure that high levels of precision will be part of the product mix.

For More Information:

Hi-Tech Mold & Tool

(413) 443-9184

sales@hitechmoldtool.com

www.hitechmoldtool.com

RELATED CONTENT

-

How to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

-

Baffle Blades in Plastic Injection Molds

Turbulent-flow plastic baffles eliminate blow-by, significantly improving cooling and cycle times.

-

Make Mold Cooling Easy and Effective

Strategies for designing an effective cooling system with less time and effort.