Adi Group Encourages Pre-Apprenticeship Program for Next-Generation

In a pandemic-stricken climate, a pre-apprenticeship approach may offer up a practical learning path to those young people whose formal education has been disrupted.

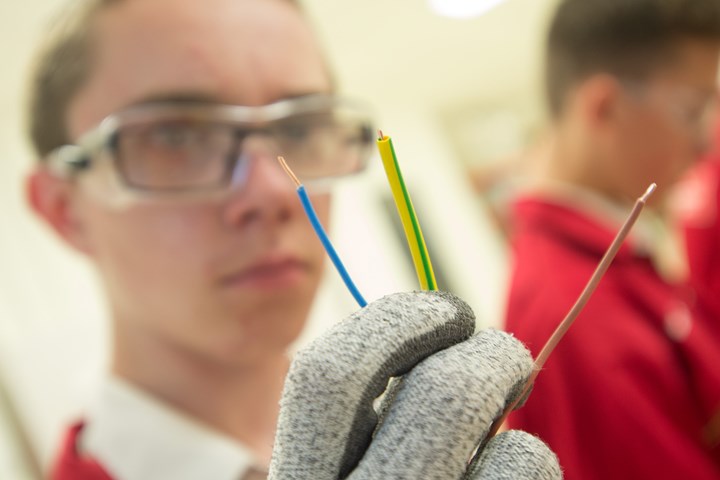

Photo Credit: adi Group

The COVID-19 pandemic has had far-reaching impacts on just about every industry and sector. But arguably, none have been as damaging than its effects on education.

Schools and universities were some of the first institutions forced to shut at the onset of the pandemic, and almost a year later, not much has changed for students. With little to no face-to-face teaching time, playing catch up with the curriculum and exam cancellations, uncertainty prevails for young people all over the country.

Research published by AccessHE, the network for social mobility through higher education for London, has revealed that over 27,000 students could miss out on college this year through COVID-inflicted learning loss, with the Association of Colleges also voicing their concerns in this area. Further, these effects are likely to have a knock-on impact to futures, with many rethinking career paths and seeking alternative routes to employment. So, now, more than ever, focus should be given to apprenticeships.

Backing this notion is James Sopwith, Group strategic account director at the multidisciplinary engineering company, adi Group (Urbandale, Iowa). Here, on National Apprenticeship Week 2021, James explains how the business’ tried and tested pre-apprenticeship project, which is now in its fifth successful year, is something that more employers should begin to consider.

“The pre-apprenticeship scheme is an EAL-accredited program, that each year, allows a class of twelve 14-16-year-olds to gain valuable insight into the engineering profession, as well as the professional world of work, alongside completing their normal curriculum-set studies.”

Students enrolled in the program spend one afternoon a week in a professional, hands-on setting, which happens to be at adi’s custom-built workshops in Kings Norton. Its location works well with the program’s exclusive partnership with nearby North Bromsgrove High School.

“The virus has already taken so much from us but taking these steps now will ensure we do not lose this next generation too.”

But although exclusive, the project’s fundamental design is that of promoting greater accessibility to the engineering profession to individuals who typically have limited opportunities to learn about and experience all that a career in the field has to offer.

“That is exactly the reason focus should be given to apprenticeships by employers in the current commercial and COVID-stricken climate,” says Sopwith. “In engineering, it’s a chance to re-educate young people who so often have misconceptions of what an engineer is. But in reality, as any one of us in the field know, those low pay, dirty environment perceptions couldn’t be further from the truth. By changing the way this group sees the wide-ranging job opportunities within engineering, we will ultimately be securing a more sustainable future for the field. We also want to encourage more women into the trade, more diversity and more young people in general as a matter of urgency as the STEM skills gap widens.”

While attention has been given to the shortage of skills required to fulfill engineering roles in recent years, Sopwith says, it is already apparent that the pandemic’s impact on education will have delayed efforts until academic routes fully reopen.

“And this is one of the key benefits of taking a pre-apprenticeship approach instead. It opens up a practical learning path to those young people whose formal education has been disrupted, as well as offering an opportunity to those less keen on entering the profession through traditional academic routes.”

adi reiterates this as the primary reason it chose to partner with North Bromsgrove High School, which at the time of design and delivery of the first program, was looking for a unique student proposition to compete against other local schools in the area, as well as a broader curriculum. The pre-apprenticeship offering was a key way to attract more students and supplement pupils’ learning with additional skills and experience that would go on to improve their academic performance and future prospects.

According to adi Group, the approach has already proven a success, with various candidates from a diverse range of backgrounds having gone on to achieve great personal results, and make a significant impact on the business.

How did this all begin? adi began with the vision of a former apprentice, Alan Lusty, and has become committed to continuing its efforts in ensuring the route remains a pivotal part of the industry’s future, no matter the challenges it faces. So, despite cut backs by other employers looking to save budget amid economic downturn, and disruption to the in-school learning side of the program, the project has reportedly remained in full swing. And the hope is that the business will continue to source employees from its pool of apprentices for years to come.

“We believe it is time for others to consider the option too. We have already collaborated with other like-minded businesses to replicate the tried and tested pre-apprenticeship project structures, and we are expecting to see more interest as its benefits, and remedies to the market’s current challenges become more apparent,” adds Sopwith. “So, while we’ve committed to doing our part, we can’t make the impact we would like to alone. It is going to take collective effort from manufacturers and engineering companies across the industry. It might even be an idea to take inspiration from other businesses operating in STEM fields and learn from their efforts in tackling the skills gaps, too.”

Notably, BP Oil has long committed itself to supporting STEM education, investing in research programs to understand young people’s perceptions, opportunities and representation in such fields, and then using the insight to build capacity in education in science areas across the U.K.

“Engineering could certainly benefit from a similar approach,” says Sopwith. “While our pre-apprenticeship project originates in Birmingham, that’s not to say willing engineering businesses cannot open the opportunity up to a much wider population in order to accelerate our sustainable future.”

He concludes: “The virus has already taken so much from us but taking these steps now will ensure we do not lose this next generation too. And as the UK Government encourages us to ‘train’, ‘retain’ and ‘achieve’ this Apprenticeship Week, we would encourage businesses take from it more than just buzzwords to really transform our industry for the better.”

Related Content

MMT Chats: Acquisition Trends and Lessons for Mold Builders

Jim Berklas is a former full-time M&A lawyer for several of the largest private equity firms in the country and has 25 years of M&A experience and 200 closed transaction. Today, he is founder and M&A Leader with Augmented Industry Services. He joins me for this MMT Chat on mergers and acquisitions trends and strategies within in the mold manufacturing industry. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreLeading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreConsiderations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

Read MoreMachine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreRead Next

MMT Chats: Working On and In an Apprenticeship Program

Four years later I follow up with two young moldmaking professionals who continue to help develop the apprenticeship program that got them to where they are today.

Read MoreBig Kaiser Presents Fifth Annual Donation to National Robotics League

Big Kaiser and its customers raised $6,275 in two months to contribute to hands-on STEM learning experiences for NLR students.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 1.png;maxWidth=300;quality=90)

_970x250 3.png;maxWidth=970;quality=90)