Tool Steel

Machine-Ready Blanks Help Mold Shops Reduce Production Time

Plate and sheet distributor TCI Precision Metals offers made-to-order square, flat and parallel blanks in a variety of material options and with added feature options.

Grace Nehls

Senior Managing Editor, MoldMaking Technology

Cutter Designed for Roughing in Face, Profile Milling Operations

The Sandvik Coromant CoroMill MR80 now caters to steel milling applications, which require the security of a round cutting edge — for instance, when face and pocket milling mold bases.

Read MoreAlro Steel Expands Metal Offerings Via Pottinger Steel Acquisition

Third company purchase this year brings carbon steel, alloys, stainless steel, aluminum and other metals under Alro Steel’s distribution capabilities.

Read MoreMicro-Milled Steel Plate Cuts Mold Build Times by 10-15%

Steel 21 emphasizes its tighter tolerances, improved surface quality and speed of processing using the patented “21 Micro Milling” process.

Read MoreVIDEO: Qualifying Modified H-13 for 3D-Printed Tooling

Next Chapter Manufacturing and International Mold Steel discuss their partnership to qualify a modified H-13 for tooling applications.

Read MoreHow to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection, there are many variables that can dictate the best option for moldmaking.

Read MoreCoating Technology Enables Tough Mold and Die Steel Machining

Millstar, a part of Cole Tooling Systems, presents a multi-layer hybrid nanocoating for cutting tools that provide key benefits for increased efficiency in any machining operation.

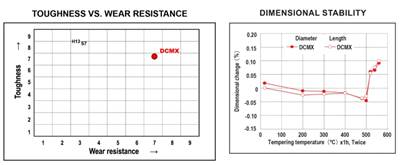

Read MoreTool Steel Alternative to S7-Based Molds

NPE2024: International Mold Steel showcases its DCMX steel as an alternative to S7, providing mold builders uniform hardness for even machinability and clean welds and other benefits.

Hannah Zelinski

Editorial Assistant

Mold Materials Guide Eases Steel Selection

Newly released Materials Guide from Swiss Steel Group offers mold builders a quick and easy way to navigate the company’s steel solutions, applications.

Read MoreShaping Steel Enables More Complex, Efficient Injection Molds

AddUp’s AISI 420 stainless steel is commonly used to manufacture molds for plastic injection molding, as it has high mechanical strength and good corrosion resistance.

Read MoreQualified Tool Steel Enhances Thermal Transfer, Long Tool Life

Next Chapter Manufacturing has successfully qualified HTC-45 tool steel, an optimized version of H13, to support better thermal transfer and faster cycle times for molders and die-casters.

Read MoreWhat You Should Consider When Purchasing Modified P20 Steel

When buying P20 steels that have been modified, moldmakers must be aware of the variations and key issues that affect delivery, cost and lead times.

Read MoreHigh-Grade, Ultra-Fine Grained Steel Attained Via Novel Heat Treatment

Swiss Steel Group applies its Extreme Performance Technology (XTP) treatment to steels for enhanced dynamic and mechanical characteristics.

Read MoreProject Reveals Added Benefits of New P20 Grade Steel in Machinability, Cycle Time and No Stress Relief

MoldMaking Technology's Christina Fuges talks with General Motors' Shane Appel about a project testing a new P20 steel grade's dimensional stability.

Read MoreReliable, Efficient 3D Printer for High-Quality Tool Steel Components

The updated TruPrint 2000 underscores Trumpf’s focus on the tool and die industry, including a larger, square build plate and various features to ensure high quality and mass production.

Grace Nehls

Senior Managing Editor, MoldMaking Technology

How to Produce More Accurate Molds and Reduce Rework

Patented micro-milling process for manufacturing steel plate flat and parallel helps mold builders shorten mold build times and increase accuracy.

Read MoreThree Considerations for Mold Steel Selection

Although a big challenge is selecting the right steel for the right job, steel selection has never been better in regards to quality, price and delivery speed. Here is a simple checklist when selecting your next mold steel.

Read MorePVD-Grade Carbide Milling Inserts Address Mold Machining Challenges

The new PVD grade from Walter USA is now reportedly capable of 30% greater performance in stainless steels and heat-resistant super alloys, and up to 75% greater performance in steels than comparable grades.

Read MoreAdvances in P20 Steel Potentially Eliminates Need for Stress Relieving After Rough Cutting

Omega Tool Corp. compares conventional, new P20 grades side by side in production fascia tools, finds no downside.

Read MoreHow to Lower Cycle Times With the Right Tool Steel

Combining excellent mechanical properties, high wear resistance and high thermal conductivity in a specialty tool steel yields cycle time reduction.

Read MoreAlro Steel Set to Acquire Access Metals

The acquisition is expected to enable Alro to grow its customer base in the eastern United States while providing improved service for cut-to-size metals.

Read More3D Printing Tool Steels Reformulated for More Flexible, Less Brittle Filaments

Markforged has reformulated its H13 and D2 tool steel filaments for use with its Metal X 3D printing system.

Grace Nehls

Senior Managing Editor, MoldMaking Technology

Self-Venting Mold Steel for Defect Prevention

High-tonnage pressed and sintered, porous metal Vortex removes the difficulties of trapped gas in the mold cavity through a system of interconnected pores.

Read MoreMetal 3D Printing Technology Targeting Moldmaking is Launched

Mantle announces the commercial launch and availability of its metal 3D printing technology, eliminating or reducing operations traditionally required to make precise, durable steel tool components.

Read MoreMoldMaking Technology's Top-Viewed Content in 2022 So Far: Features

A list of the most-viewed features in MoldMaking Technology from January-May 2022, from vertical machining to achieving the best mold finish. Give your favorites another look or catch up on what you might have missed.

Read MoreModified Composition Enhances Stainless Steel Capabilities

Edro introduces Böhler’s M333 Isoplast stainless steel which has been manufactured via a new melting technology for best-in-class polishability, conductivity, toughness and corrosion resistance.

Read MoreCorrosion-Resistant, Highly Machinable Tool Steel

Opticut mold steels from Swiss Steel Group member Deutsche Edelstahlwerke apply a novel treatment to the material to eliminate the deterioration caused by the addition of sulfur.

Read MoreCorrosion-Resistant, High-Hardness Mold Steel for Optimal Surface Finishes

Uddeholm’s premium Tyrax ESR can reduce polishing time by 40-50% and is suitable for long run production molds and high-performance plastics.

Read More

_300x250 3.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)