Five Axis

How to Implement Five-Axis Mold Machining for Higher Productivity, Versatility

Understanding the basics of five-axis capabilities justifies the investment, but exploring all the multi-axis machine benefits and approaches enhances the return on investment.

WatchMold Builder Invests in Five-Axis Milling to Open the Envelope

NPE2024: Mold-Tech Inc., dedicated to complete quality and support, continues to add to its hard milling equipment department with the Makino D200Z, enhancing mold lead times, accuracy and efficiency.

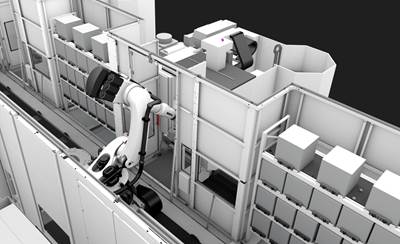

Read MoreUsing Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

Read MoreVMC Provides Versatile Machining of Complex Parts

The Mazak North America VC-Ez 20X vertical machining center features a 25-horsepower 12,000-rpm CAT-40 spindle with a 30-tool-magazine automatic toolchanger.

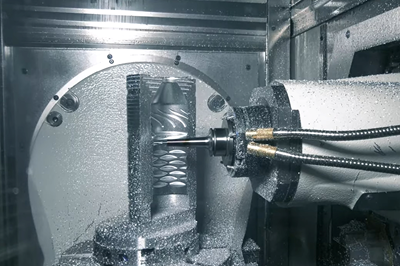

Read MoreHybrid Multitasking Five-Axis Brings Subtractive, Additive Processes to Moldmakers

Mazak’s VC-500A/5X vertical machining center delivers hybrid multitasking and hot wire deposition to meet machining and additive needs.

Read MoreSpace-Saving Five-Axis Provides Productive Mold Machining

The Grob G150 universal machining center and its spatial accuracy enhances its performance with complex, high-precision components.

WatchFive-Axis VMCs Attend to Versatile Machining Task Needs

Mold shops can choose from YCM Technology’s CF/CX or RF/RX Series of machines whether for simple or more demanding machining operations.

Read MoreHigh-Efficiency Milling Excels in Specialized Parts Production

GF Machining Solutions Mikron Mill E 500 U offers moldmakers a sturdy, reliable five-axis machine with integrated automation opportunities.

Read MoreMachining Center Provides Robust, Dynamic Milling Qualities

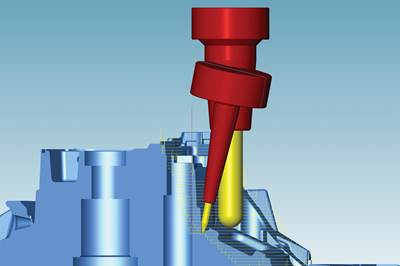

Roughing and finishing deep mold and die cavities is optimized using Chiron’s FZ 16 S five-axis machining center equipped with an HSK-A 100 interface, enabling reduced chatter, dynamic machining and the ability to tackle difficult materials.

WatchFive-Axis Vertical Mill Increases Mold Shop Capacity by Reducing Setups

Zero Tolerance now processes blocks — from squaring to waterline drilling to rough and finish milling — on a single five-axis CNC mill, reducing setups and moving blocks in/out of multiple machines without sacrificing accuracy and surface finish.

Read More

_300x250 1.png;maxWidth=300;quality=90)