WEBINAR: Want to Know How a Leadtime Leader Does It?

Well, one component to winning more jobs, competing on price, shortening delivery times and meeting quality demands is advanced automation. Listen to this archived webinar with 2015 Leadtime Leader Winner Cavalier Tool sharing its success in partnering with the right software supplier.

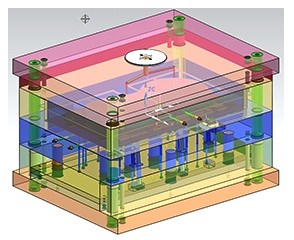

Mold manufacturers are experiencing intense global competition, and that is requiring them to reduce tool cost, decrease tool design through manufacturing leadtime and improve product quality. One way to take on these challenges is using the right software. This week's webinar hosted by Siemems PLM Software discussed and demonstrated how NX™ Moldwizard software can transform the tooling development process with advanced knowledge-driven automation that can improve overall productivity, accelerate the process, reduce waste and cost and improve quality.

NX Mold Wizard provides a structured workflow based on expert best practices, automation of mold-specific design tasks and libraries of standard mold components. It is a step-by-step process that promotes the most efficient workflow, while integrating complex elements of design technology into automated sequences. Supporting the value of this type of software investment was Brian Bendig, president of Cavalier Tool & Manufacturing, MoldMaking Technology's 2015 Leadtime Leader Award winner.

Listen to archived webinar today.

Related Content

-

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

-

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)