WEBINAR: When It Comes to Cutting Tools, It's Not About Price, It's About Performance

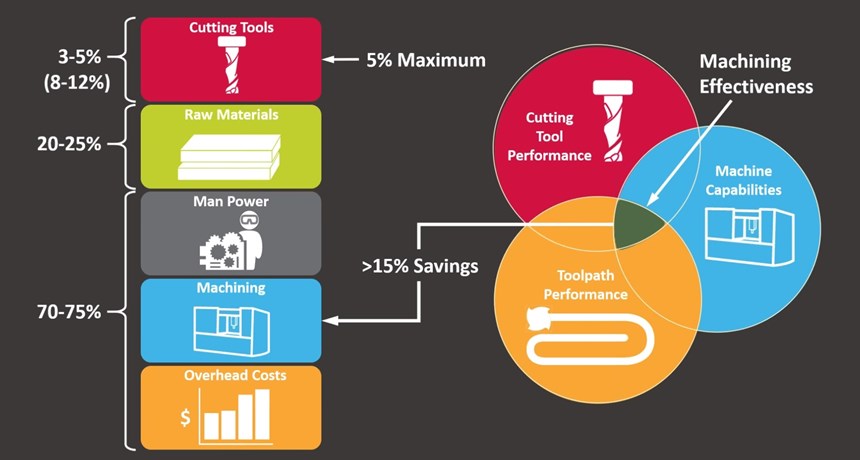

The dirty little secret about cutting tool cost is that it’s not about price, it’s about overall costs. Check out this free online archived webinar to learn all the details of cutting tool performance testing.

Do you understand the difference between cutting tool price and cutting tool cost? Do you know how cutting tool cost impacts job profitability? Do you know why a CNC programmer is vital to cutting tool purchases? To find out the answers to these questions and more, listen to this free recorded webinar.

Presenter Stas Mylek has worked at CNC Software, Inc., developers of Mastercam, for more than 12 years in the roles of Director of Product Management, Senior Product Marketing, and most recently, as Partnership Program Manager. His attention now focuses on building strategic alliances and partnerships that bring new and emerging technology to the CAD/CAM market.

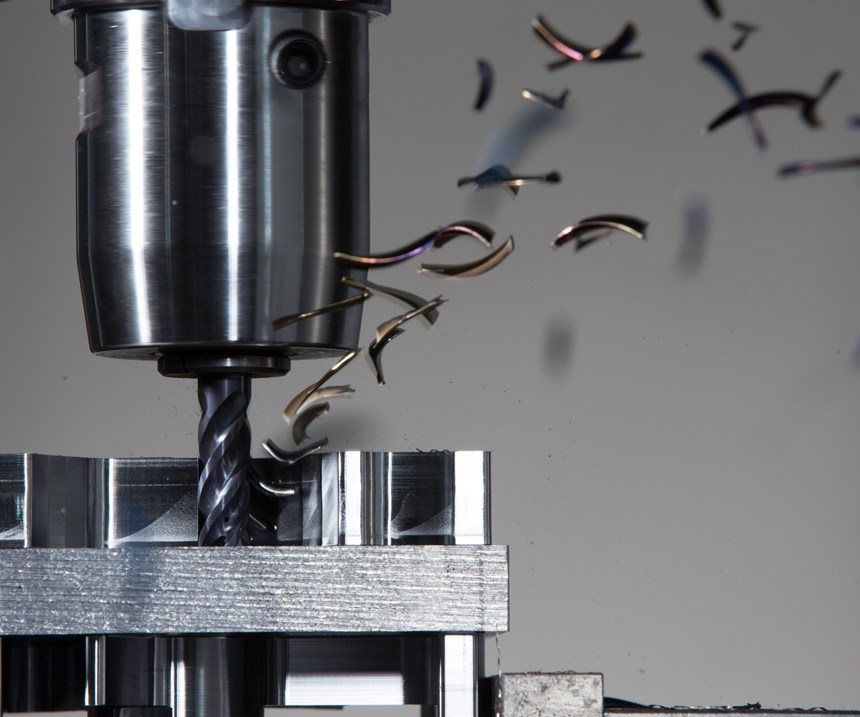

He also has authored many CAM technology articles for manufacturing trade publications, been a frequent trade conference speaker, and has conducted numerous seminars on Dynamic Motion, machining, and cutting tool technologies. Using this wealth of knowledge and experience, Stas spent time an hour diving into a variety of cutting tool topics.

Here is a peek at some of the questions raised during the Q&A:

Q: This project analyzed solid carbide tools. Can the same be done for high-feed or inserted cutters?

A: Yes, the same calculations hold true except you need to factor in the additional cutting edges and the cost per insert times the number of inserts per tool. We’ve started running some tests on these as well comparing various styles and approaches.

Q: In your tests, does the higher-priced tool win each time?

A: The higher-priced tools tend be on top for several reasons: engineering, quality carbide, coatings, design, quality--much of what you expect out of a top tool.

Q: Can the same exercise be done to compare solid carbide against a high-feed tool approach?

A: Absolutely. We ran a recent test in titanium where the high-feed mill approach performed very well. Still, not as well as solid carbide, but very respectable. Again, everything comes down to measuring results.

Q: Noticed there were no vendors listed, just Tool A through D? Do any vendors perform at the top?

A: Well, the goal of our exercise was to see who came on top but to understand what determined the actual tool cost and to create a method for identifying which tool produced the greatest bang for your buck. It was about understanding what the true cost of a tool really was. We work with many of the best cutting tool manufacturers out there, and depending on the application, anybody can win in a given instance. The benefit comes from testing results.

Q: Is the calculator that you used available?

A: We initially created this to test performance. It’s recently been expanded to include insert or high feed cutters as well as factoring in things like regrinds. There’s a possibility we could make it available, so I’d say, keep an eye open.

Q: Is there a specific make, model, or material of tool that lends itself best to issues you covered?

A: No, Dynamic Motion is as near to a universally applicable strategy as we’ve ever developed.

Q: Are these techniques exclusive to milling, or are there other applications?

A: The basic concept has been expanded to turning for button inserts, as well as modified and rethought for specialized applications like CoroTurn® Prime inserts.

Q: Does a shop need a state-of-the-art or “high speed” machine to benefit from these concepts?

A: Although there are inherent benefits to more modern machines, shops can see a dramatic improvement in almost any milling machine/tool combination.

Q: There are several feed rate optimizers on the market. How do these help with the tool use issues you discussed?

A: They’re useful for a variety of milling toolpaths. We even have a feed rate optimizer in Mastercam (HighFeed). As it relates to Dynamic, though, there’s not much to gain from running those paths through a feed rate optimizer. Dynamic motion is already built to target a consistent feed rate while adjusting the engagement to produce an even chip load.

For other archived webinars on everything from design to first shot, visit https://www.moldmakingtechnology.com/webinars.

Related Content

How to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

Read MoreMold Innovations Power Unique Auto Lighting Elements on Hummer EVs

Diamond machining, electroforming of micro-optical inserts and modified latch-lock system help injection molds produce unique forward lighting elements.

Read MoreTolerancing in Mold Design, Part 1: Understanding the Issues of Conventional Bilateral Tolerancing

Mold designers must understand the location, orientation and form limitations of conventional tolerancing before changing to another dimensioning system.

Read MoreMoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

Read MoreRead Next

A CAD-for-CAM Toolbox Helps Moldmakers Design Better Molds

An important CAD function that a CAM package should offer moldmakers is a set of specialized CAD-for-CAM tools that focus on the machinist’s needs after the machinist opens the part file.

Read MoreAdvanced CAM Software Streamlines Solid Modeling, Toolpath Creation, Verification and Connectivity

Advanced CAD/CAM improves performance of cutting tool designs, probing, process simulation and verification and data gathering and monitoring.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 1.png;maxWidth=300;quality=90)

_970x250 4.png;maxWidth=970;quality=90)