In the words of Henry Ford: “If you always do what you always did, you’ll always get what you always got.” A statement to consider as we move forward into the future of manufacturing.

Manufacturing has become increasingly more organized, custom-made, cellular and automated over the years, but as digitization becomes the new standard, competitive pressure among manufacturers will intensify, and only the innovative will advance. Digitization requires new technology ready for Industry 4.0. Every shop has heard this buzzword, but does every shop truly understand its impact? To unravel the mystery of Industry 4.0, mold builders need to understand how industry reached 4.0 and what Industry 4.0 means to the OEM, injection molder and toolmaker (see sidebar).

For many plastic processors and moldmakers, robotics and automation are only the first things that come to mind when thinking Industry 4.0 integration. It is when you start thinking of machine-to-machine connectivity, data gathering, measurable outputs and artificial intelligence that you are looking at connecting 4.0 (IoT) technology into your tooling and molding process.

The first step to applying Industry 4.0 is ensuring that every employee understands that it will help resources better comprehend and measure the dynamics that are taking place between the press, mold, and resin. Industry 4.0 is not intended to replace people, but rather, to assist people in making educated decisions by using the data that is generated. Having people understand this principle is key to a successful implementation of Industry 4.0.

Next-Level Tooling

So, what does this mean to today’s mold builder? Well, a mold builder’s primary goal is to provide the customer with the utmost quality, which demands the use of the latest technology, such as Industry 4.0. One such OEM looking toward the future by using Industry 4.0 is the mold manufacturing team at Scholle IPN.

Scholle IPN is a global packaging company that manufactures flexible packaging materials for a variety of industries. You may not have heard of us, but we guarantee you’ve interacted with our products that are used around the world in dispensing everything from soda, smoothies and coffee to motor oil and insecticides used in industrial farming. We engineer flexible packaging solutions that are safe, natural, economic and sustainable for 22 different markets. Our products are made around the globe — not so we can produce cheaper elsewhere but to effectively serve and produce right in the markets where we operate. Our molds use a variety of hot runner systems that are generally gated directly to the part, in high cavitation molds (16 cavities or higher). So, as we move towards the future and create new products or re-tool our core products, we need to look at the most technically advanced tooling available. With that objective in mind, the team at Scholle IPN set out on its Industry 4.0 journey to take its tooling to the next level: Tooling 4.0.

In the Industry 4.0 era, engineered molds with digital outputs will be the norm, and the mold supplier committed to “engineered” molds is the mold builder of the future.

MoldMaking Technology Editorial Director Christina Fuges asks Scholle IPN Senior Tooling Manager North America to define Tooling 4.0.

The Plan to Tooling 4.0

The Scholle IPN North American Tooling Team started the process by creating a tooling assessment form to measure where the company was at this specific moment in time.

The team created the form to analyze the condition of all molds, mold preventive maintenance, mold engineering data, spare part inventory, mold conversions, mold AMs (or daily shift preventive maintenance), toolroom skills and tool room equipment. The team then drilled down deeper into each area to find measurable data. Within these categories, we compiled data from the production floor.

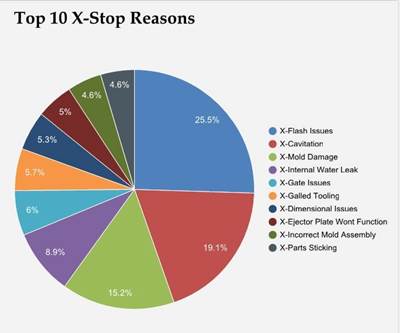

For example, in the mold condition category, we measured data that would help assess the overall status of each plant’s fleet of molds. The data we captured included the cause of mold stoppages, any molding heldware (nonconforming product) and targeted cycle times, to name a few. Once each plant completed this step, in each category they established a series of prioritized goals. These goals would then drive the plant's continuous improvement tooling projects, such as collecting data to ensure that the Standard Operating Conditions (SOC) were updated to reflect the current molding conditions that produced in-tolerance parts. Each plant will work on its prioritized issues for six months to a year and then re-assesses the current state.

It was then time to develop the plan to take tooling to the next level by using scientific molding and data gathering, which demanded the right tool, process and measurable outputs. The purpose of this next step is to learn what is going on inside of the mold during each cycle by taking measurements of the physical dynamics. Items to measure include pressure, temperature, and time, for example. So, instead of flying by the seat of our pants, we can now fly by instruments and actually understand what is happening inside of the mold and then make any necessary adjustments.

Some steps the Scholle IPN team included in the plan were:

- Meet cycle time requirements with new mold components by using additive manufacturing, better venting or monitoring with pressure sensors to provide feedback through the mold, into the press, then onto the production environment.

- Test mold designs virtually with software to get feedback and to set baselines for cycle time.

- Test a mold with software and sensors to see where the team needs to optimize for cooling, pressure, pack, balance, etc.

- Qualify a mold using a scientific method (see sidebar) to create a Design of Experiments (DOE) (see sidebar) to generate the process window and to set sensors minimum/maximum levels.

- Use high-speed electric molding machines that feedback information via pressure and temperature sensors and relay information back to the system, keeping the mold in control and achieving lights-out manufacturing.

Next, the team reviewed the fleet of molds in its Northlake plant location and chose a project based on historical downtime issues: two identical molds experiencing short shots and imbalance issues. The primary objective was to learn about the pressure dynamics that were occurring between the molding machine and the mold.

The team designed this project to run in two phases. During Phase One, the team ensures that the hot runner system is not losing any heat due to long drops required by the mold design (moving or floating components in the “A” half are triggering the long drop lengths). The team determined that full heat containment is required on these molds before moving to Phase Two.

During Phase Two, the team installs RJG pressure sensors into the molds and molding machines, runs a DOE to set the high and low limits for the system to measure and re-programs the robotic removal system to determine whether to accept individual parts or to send an individual part to the scrap bin.

Now that these 4.0 components are “talking” to one another, a non-filled part will then be placed directly into the reject bin. This is Scholle IPN’s first continuous improvement project on injection molds using Industry 4.0 technology: Tooling 4.0.

MoldMaking Technology Editorial Director Christina Fuges interviews Scholle IPN Senior Tooling Manager North America Don Smith about the difference between mold design and mold engineering.

Mold Builder of the Future

To apply Tooling 4.0 to future projects, Scholle IPN made its team and several quality tool builders’ as strategic partners. Scholle IPN looked, and continues to look for, forward-thinking mold manufacturers possessing all tools in the toolbox but will not exclude shops without all the tools, as long as they are interested and willing to take the next steps with them.

A top skill set Scholle IPN was looking to implement with its mold-building strategic partner was engineering injection molds instead of designing injection molds. Engineering, by definition, is the application of mathematics, as well as scientific, economic, social and practical knowledge to invent, innovate, design, build, maintain, research and improve structures, machines, tools, systems, components, materials, processes, solutions and organizations. Design is the intentional creation of a plan or specification for the construction of an object or system for the implementation of an activity or process.

Engineering a product (in this case, the injection mold) means to achieve measurable outputs via mathematics and science. Outputs include balancing runner systems (Beaumont theory), mold temperature control (calculate GPM; temperature sensors), conformal cooling (estimated cycle time and part quality targets) and calculations for optimized venting (pressure sensors). In the Industry 4.0 era, engineered molds with digital outputs will be the norm and the mold supplier committed to “engineered” molds is the mold builder of the future.

Here are some expectations that OEM/suppliers might place upon the mold builder of the future to take full advantage of advancing technology.

- Reverse engineering. Ability to take older molds and mold components and accurately measure and create, as built, 3D models and prints.

- Virtual mold analysis. Ability to digitally create a molding process with measurable targets before engineering the injection mold, establish measurable cycle times (fill, pack, cooling, pressures), determine warp, venting, part sizes and steel safe areas, and use pressure and temperature sensors, as well as other scientific molding information, and possess end of arm tooling and robotic part removal knowledge.

- Mold engineering capabilities. Ability to output 3D mold models for virtual analysis, as well as fully detailed/toleranced drawings (.dwg output) and possess a detailed mold assembly manual with PM recommendations.

- Hot runner system knowledge. Understanding of fixed tip, valve gate, hot edge gates, and system balancing.

- Manufacturing/measurement of interchangeable mold components. Ability to manufacture and guarantee interchangeable mold components, confirm/certify critical steel measurements, coordinate measuring machine and laser scanning capabilities.

- Experience building high cavitation, injection molds. Injection mold experience with 16-cavities and higher; pilot mold capabilities for data gathering (using mold analysis) and scientific molding experience (pressure, temperature sensors).

- Injection mold testing capabilities. FOT, FAT, SAT (see sidebar) and DOE experience, process development and turnkey capabilities.

As the prevalence of IoT increases, experts advise that the adoption of Industry 4.0 is necessary for business survival. However, moving an organization toward smart manufacturing is a multi-faceted project, regardless of company size. Simply put, Industry 4.0 and Tooling 4.0 are all about using technology to turn “dumb” products into “smart” ones.

About the Author

Don Smith is Senior Tooling Manager North America, Scholle IPN Packaging Inc.

For More Information

Related Content

Mold Builder Uses Counter-Intuitive Approach for Mold Challenges

Matrix Tool Inc. answers customers’ hard questions with creative solutions for cavity spacing, tool sizing, runner layout and melt delivery that reveal the benefits of running in a smaller press size at lower cavitation but higher yield.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreSteps for Determining Better Mold Prices

Improving your mold pricing requires a deeper understanding of your business.

Read MoreTransforming Moldmaking into Digital Industrial Manufacturing

Moldmaking and digitalization is at the core of this global industrial manufacturing company’s consolidation and diversification plan.

Read MoreRead Next

Mold Building Stats Improve Performance

Mold manufacturing is a numbers game rooted in measurement and data tracking to continuously improve.

Read MoreHow Will Industry 4.0 Impact Mold Maintenance?

Many toolrooms want to replace manual entries with electronic data when creating maintenance work orders and providing past historical issues, corrective actions and the effectiveness level of resolutions, but technicians require more information than electronic signals can provide to prove a return on investment of their time.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)