Technology Tuesday: Automation Fuels Productivity

Cruise through this week’s Technology Tuesday blog to see ways in which automation is boosting productivity and efficiency in moldmaking.

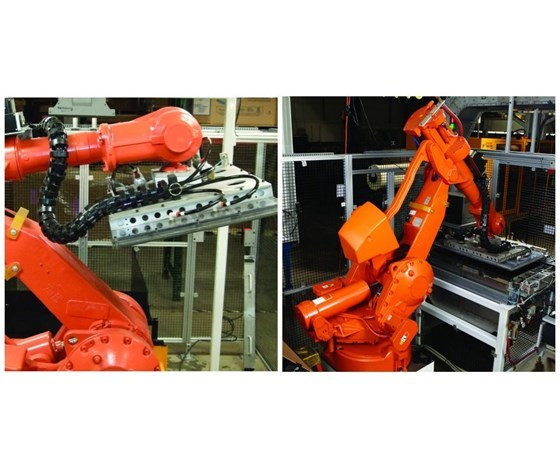

Automation helps shops respond effectively to demands for shorter lead times, lower costs and better quality. It opens opportunities to increase productivity and to efficiently use available resources. In thinking about making investments in automation, key questions emerge. How can humans and robots interact safely? How, specifically, will an investment lead to increased profits or shortened lead times? What are the latest features in automation equipment? Are investments in things like robots the best choice?

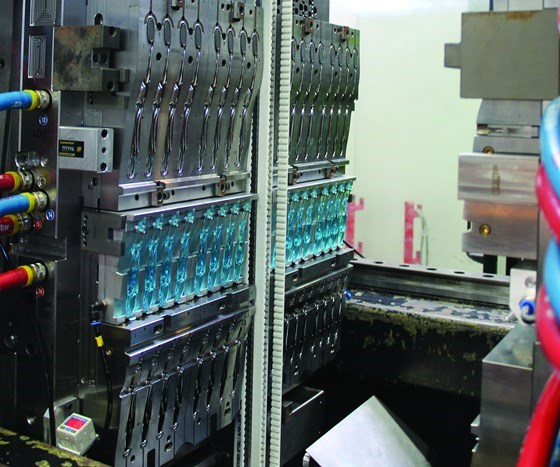

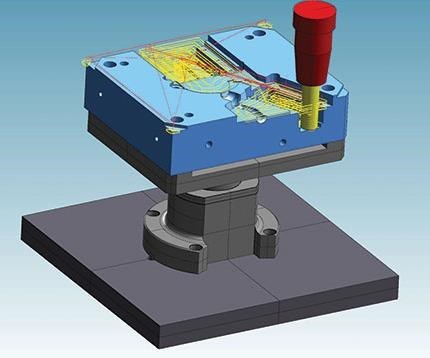

Interested in the latest automation strategies? Check out the Automation Zone. Get the latest details on automation products, like an automation cell from Methods Machine Tools Inc. that incorporates robots to produce 3D parts, or watch videos to see how automation influences shop practices in action.

Featured in this week’s slideshow are articles on the latest automation trends and strategies with suppliers and consultants from Yaskawa America, Inc., Industrial Molds, EROWA Technology Inc., Fairway Molds, Makino, Single Source Technologies, Build-a-Mold and OPEN MIND Technologies USA Inc.. Links to relevant articles are located in the slideshow captions.

Related Content

-

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

.jpg;maxWidth=300;quality=90)