Largest Amerimold Show Floor to Date; See Technology Display

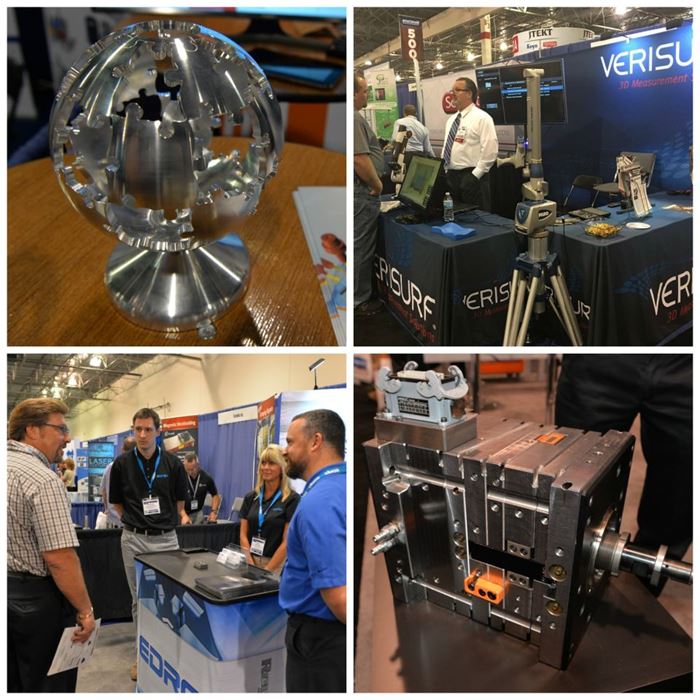

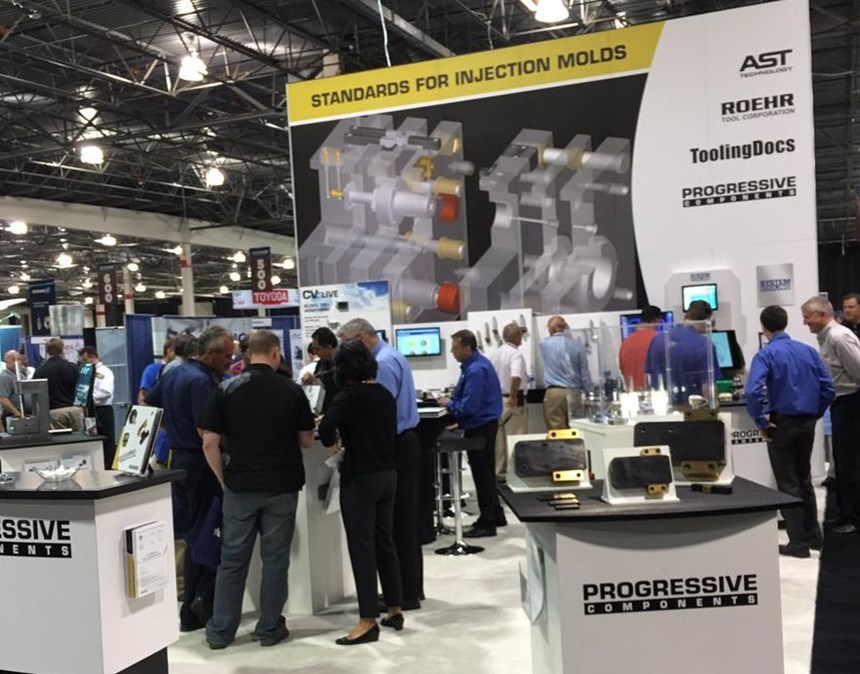

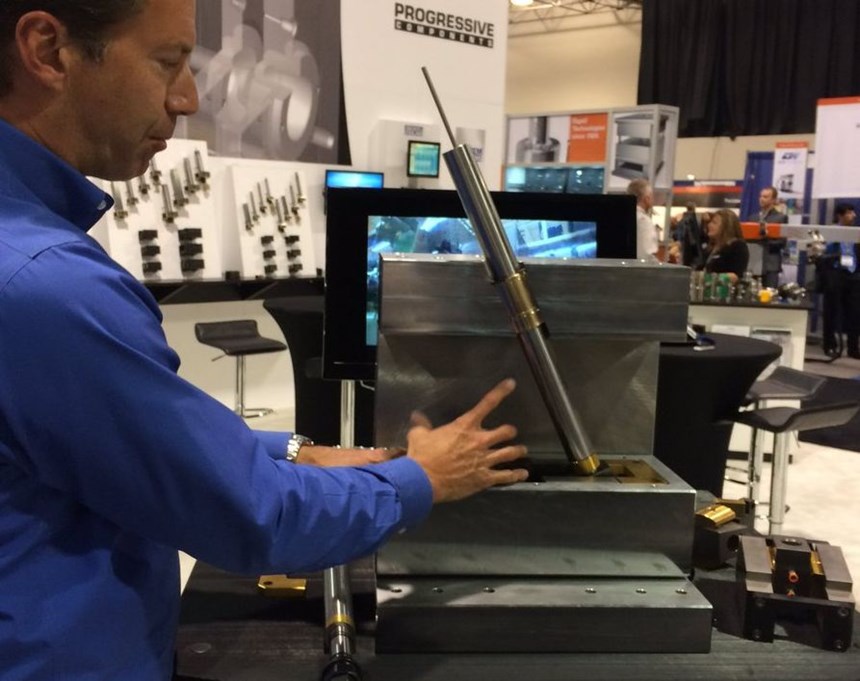

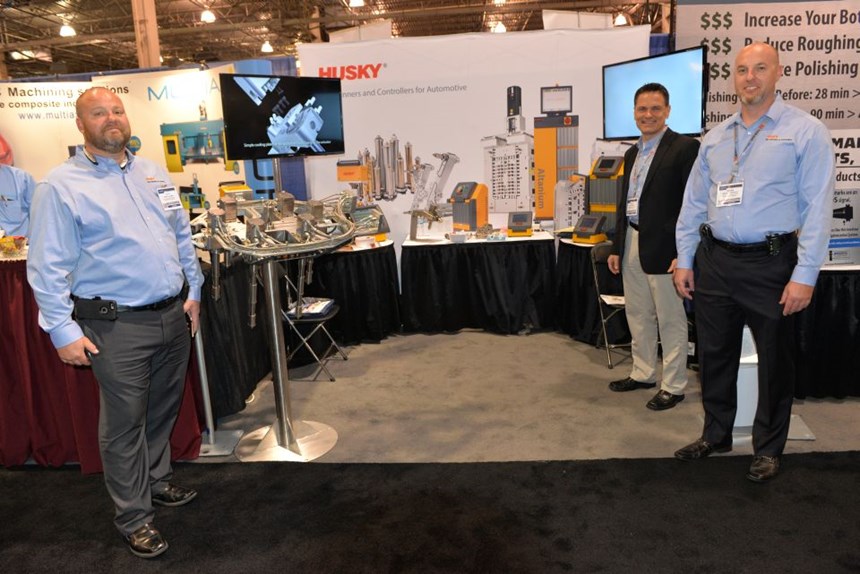

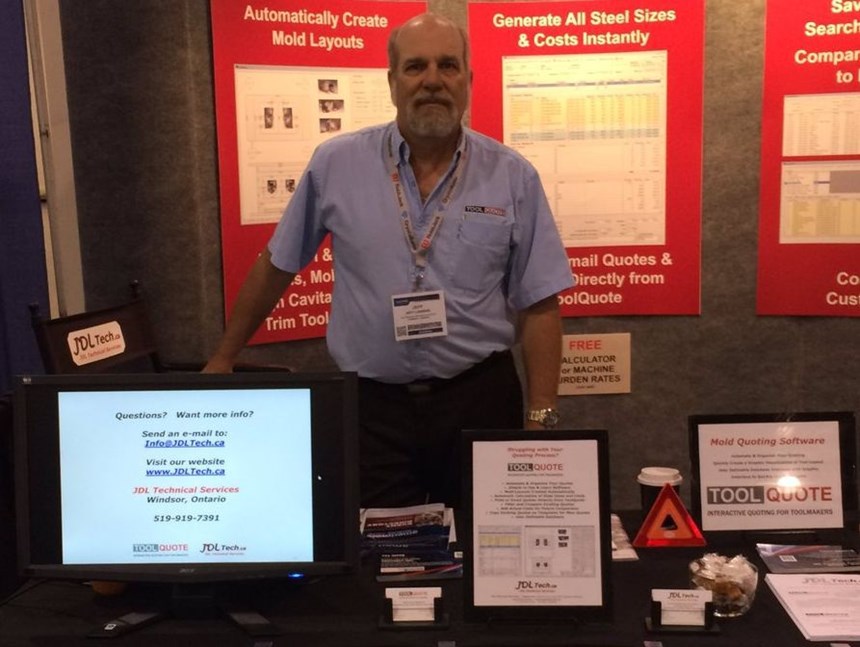

Amerimold, The Event for Mold Manufacturing, closed on June 16th, 2016, at the Suburban Collection Showplace in Novi, MI. The two-day tradeshow, technical conference and networking event featured more than 3,000 participants, representing every aspect of the plastic injection molding cycle. The Amerimold exhibit hall was the largest ever and included 200 exhibitors displaying products and services used for designing, building, injection molding and maintaining molds.

Amerimold, The Event for Mold Manufacturing, closed on June 16th, 2016, at the Suburban Collection Showplace in Novi, MI. The two-day tradeshow, technical conference and networking event featured more than 3,000 participants, representing every aspect of the plastic injection molding cycle. The Amerimold exhibit hall was the largest ever and included 200 exhibitors displaying products and services used for designing, building, injection molding and maintaining molds.

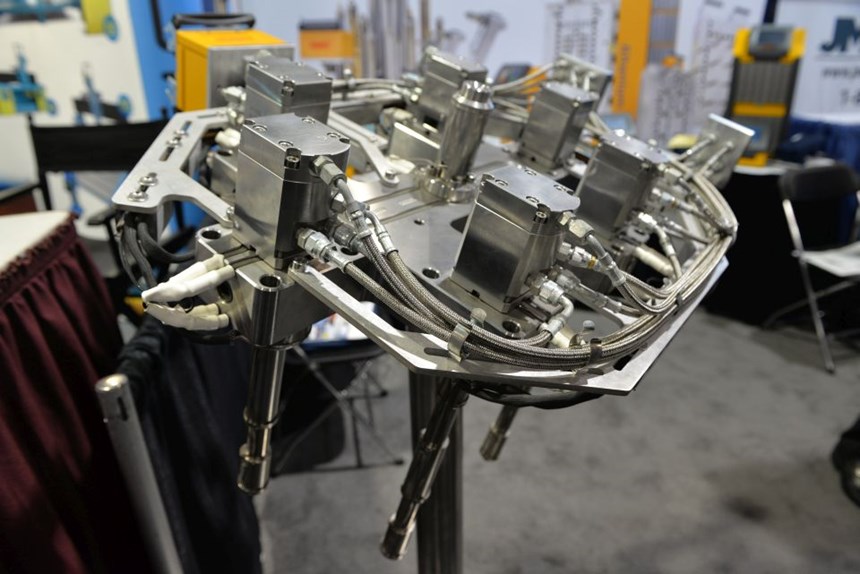

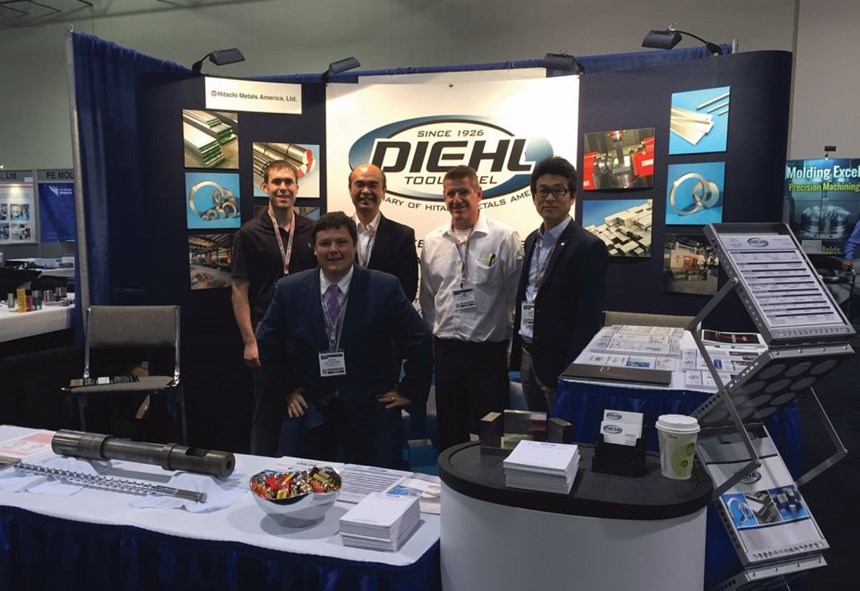

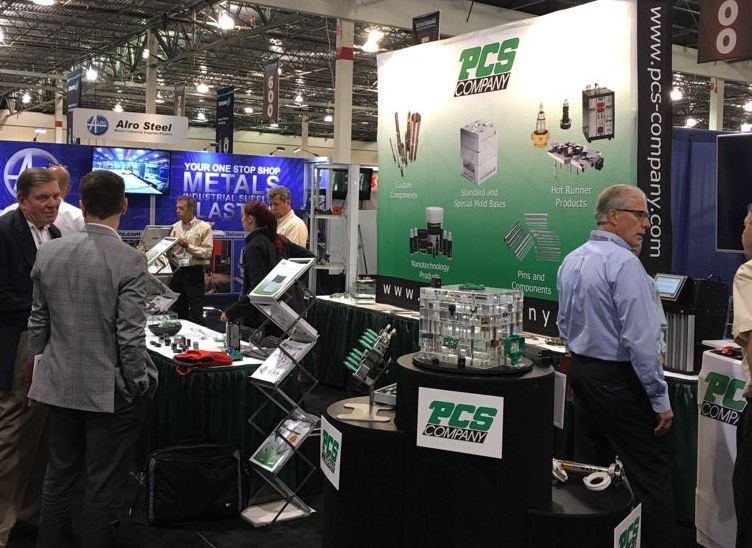

Check out this slideshow of just a sampling of the technology, processes and services showcased on the show floor.

Related Content

-

More Than Moldmaking at PTXPO 2023

The Moldmaking Pavilion returns to the Plastics Technology Expo (PTXPO) March 28-30, 2023, at the Donald E. Stephens Convention Center in Rosemont, Illinois, but there’s more to discover than moldmaking.

-

Where Mold Manufacturing and Plastics Processing Connect

The Moldmaking Pavilion is one of seven pavilions returning to the show that houses exhibitors offering technology and service solutions for your specific moldmaking needs.

-

MoldMaking Technology's Leadtime Leader Awards Competition Returns!

After a brief hiatus, MoldMaking Technology’s Leadtime Leader Awards Competition is back!