Most shops can relate to the need to save money while developing and manufacturing a product, including the mold. Let’s face it: there is a reason people still use the old phrase “time is money.” Any opportunity to save time affords the time to work on another task, such as making another part, or avoid the need to stay late to finish the last job of the day.

Traditional efforts to achieve higher efficiency in design and manufacturing processes have been unable to affect any real change within day-to-day workflows. However, today the manufacturing world is finally changing and changing fast. Technology trends like Industry 4.0 are almost forcing manufacturers to evolve to optimize work processes for higher profitability. Gone are the days of wasting time using dated workflows which, in many cases, engineers and operators have not updated in decades.

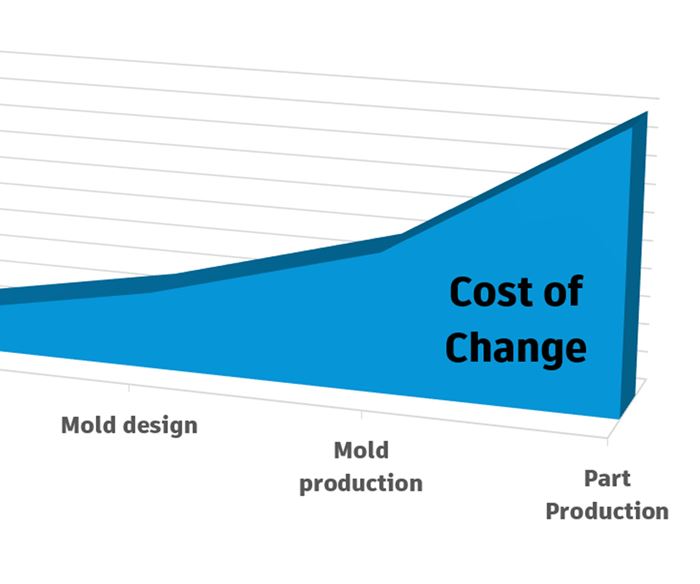

Solutions do exist to ease this evolution for mold manufacturers who agree that the most expensive mold is a reworked mold that engineers must modify, test, and transport to and from the tool shop, delaying the overall project timeline. Simulation tools can minimize, and in some cases eliminate, these delays.

Simulation Situations

Optimizing a mold shop’s work process will impact its manufacturing efficiency while helping the shop remain innovative. One work process optimization innovation is cooling simulation. Engineers often neglect this process area, despite customers commonly squeezing cooling channels in a mold as a last-minute detail, using parameters based solely on past experiences and assumptions. Even then, many engineers are skeptical of investing the time required to use advanced tools, such as simulation, to determine if the cost of cooling optimization will be worth the reward. This hesitation can be a result of their lack of knowledge and understanding of the behind-the-scenes calculations simulations use. While we should respect their traditional workflows, adopting new technologies like simulation upfront will ultimately yield long-term savings.

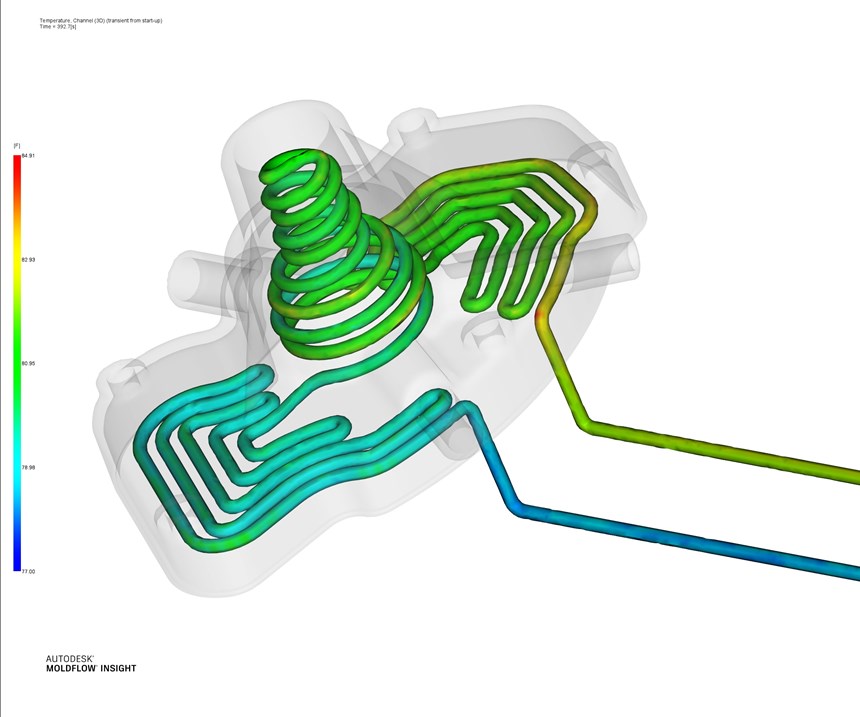

Simulation tools introduce the ability to optimize the plastic product development cycle from concept to design to production with fewer risks than physical testing. Engineers who experiment with cooling designs before cutting mold steel will be able to test more options more quickly, broadening the breadth of design possibilities. Plus, the ever-increasing complexity of part designs is also increasing the sophistication of cooling channels. Simulating cooling channel design iterations will help engineers determine such factors as hotspot locations when extracting more heat to improve part quality or cycle time reduction opportunities.

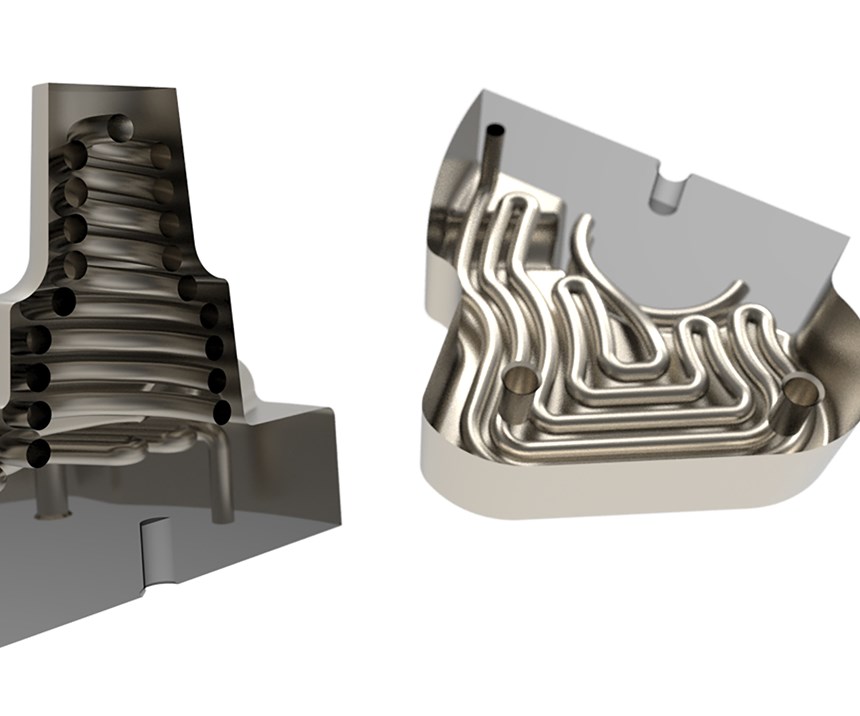

Additive manufacturing (specifically, metal 3D printing) enables mold designers to innovate cooling designs by integrating conformal cooling channels into their molds that allow the cooling channels to follow the contour of the part. This approach was previously very costly and difficult to achieve due to the shape of these channels. The ability to extract more heat through conformal cooling helps to not only create uniform cooling but also ensure part quality, and potentially reduce cycle time. When engineers use additive simulation software, which simulates 3D printing of a part, they can predict and mitigate part distortion, machine crashes during printing, and part tolerancing on those parts, further optimizing the print before using any physical material.

Metal 3D printing provides solutions for innovating old processes but also introduces new challenges. Additive technology is a heat-intensive manufacturing method that is prone to distortion (unlike traditional drilled cooling channels). Understanding this fact before initiating 3D printing is a tremendous advantage, given the higher costs associated with metal 3D printers and powders.

Simulation tools introduce the ability to optimize the plastic product development cycle from concept to design to production with fewer risks than physical testing.

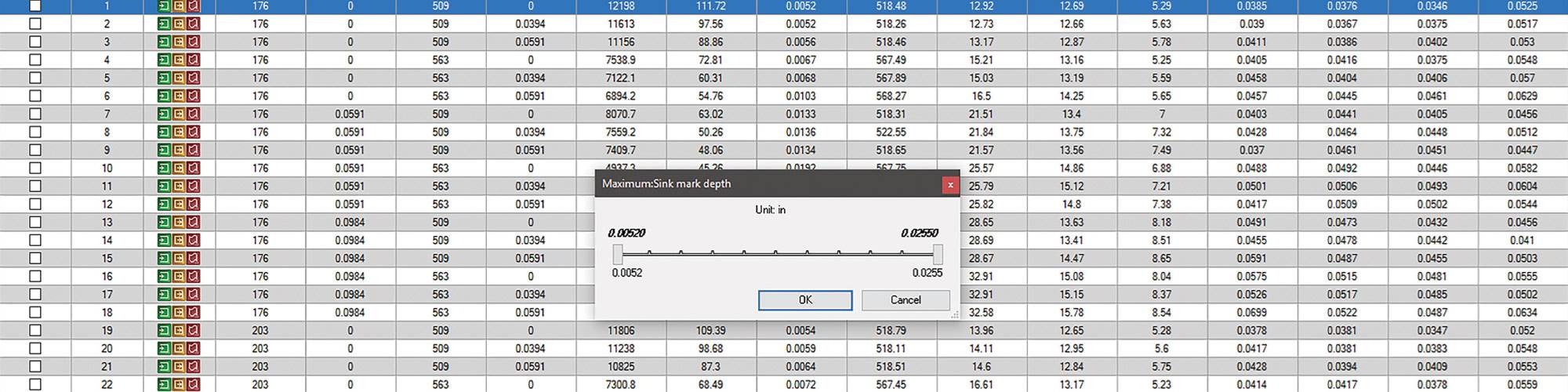

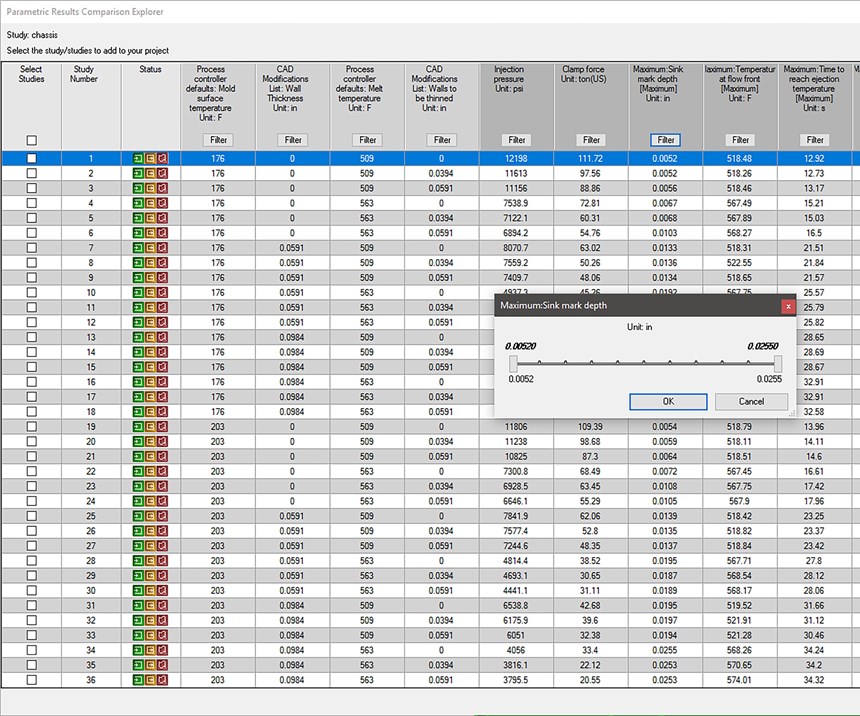

Not only does simulation help with cooling designs, but it also helps guide engineers through other design challenges. For example, material usage reduction. Simulation helps engineers develop part and mold designs that reduce the amount of material necessary to create a part. Engineers can do this through automated geometry modifications using a parametric analysis during which the simulation software runs several comparable analyses, while adjusting things like wall thicknesses, to identify the necessary balance between part quality and wall thickness. Without the use of simulation, it may be difficult to predict where material can be removed without impacting the part’s structural or quality properties up front.

Additionally, environmental pushes are causing the use of more recyclable materials, which may be less stable, physically and chemically, than traditional engineered materials. It is imperative engineers simulate these materials upfront to prevent downstream issues in the design process, such as unexpected cavity filling difficulties or part shrinkage. Simulation can also help analysts understand the robustness of the design and process during production by revealing the process sensitivity when adjusting for slight material batch variations or environmental variations.

When operators optimize these types of issues at the molding machine through a design of experiments (DOE) or other setting variation method, they tie up resources and use unnecessary material and energy creating several unusable parts. Simulating a DOE means less time is required for physical testing to locate a processing window. Engineers who use simulation instead of a trial-and-error approach to determine optimal conditions save press operators’ time and avoid the risk of a production shutdown to optimize designs and processing conditions.

Shopping for a Simulation Solution

With various simulation products available to predict plastic injection molding, deciding which one to choose can be daunting. To help identify which would be right for your shop, here are a few factors to consider:

- Short-term goals for using simulation: What exact question(s) need to be answered?

- Long-term goals for using simulation: What other uses are being considered for simulation? For example, optimizing press schedules and cycle times to maximize profit margins, or exploring benefits of other molding techniques, such as microcellular injection molding.

- Adoption time investment: How long will it take to start using the simulation software? Are there classes, support, or resources available to help? Is the software’s user interface easy to navigate?

- Fitting simulation into the existing workflow: What other software must simulation interact with (other FEA, CAD, or visualization tools)?

- Maintenance: How frequently does the software get updated? What is included within updates (new features, bug fixes, etc.)?

- Hardware requirements: What processing power, memory, or graphics requirements are needed, and will existing systems meet those as technology advances/develops? Is there a cloud-based option to help keep hardware costs down?

After a company completes its research on simulation software to identify the desired options, it is important to test each option. Shops should also speak with the technical sales teams of each simulation software supplier about their requirements and concerns, and request a demonstration on how their programs will improve productivity and part quality. Additionally, ask for a trial versions or limited-term licenses to try out each product.

Using simulation optimization tools upfront in new mold and product design and injection molding will improve product performance, raise manufacturing throughput, increase cost savings and strengthen innovation.

For More Information

About the Author

Mark Hennebicque is a business line manager at Autodesk Inc.

Related Content

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreTolerancing in Mold Design, Part 1: Understanding the Issues of Conventional Bilateral Tolerancing

Mold designers must understand the location, orientation and form limitations of conventional tolerancing before changing to another dimensioning system.

Read MoreMoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

Read MoreMold Innovations Power Unique Auto Lighting Elements on Hummer EVs

Diamond machining, electroforming of micro-optical inserts and modified latch-lock system help injection molds produce unique forward lighting elements.

Read MoreRead Next

Using Real-Time Production Data

One approach to smart manufacturing is using a single, cloud-based tool for production scheduling, job tracking and CNC machine monitoring.

Read MoreSurface Finish Considerations for Better Molds

Mold material, tolerances, texture, mold release, flow, splay, hand finishing, machining and software impact surface finish decisions.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)