Published

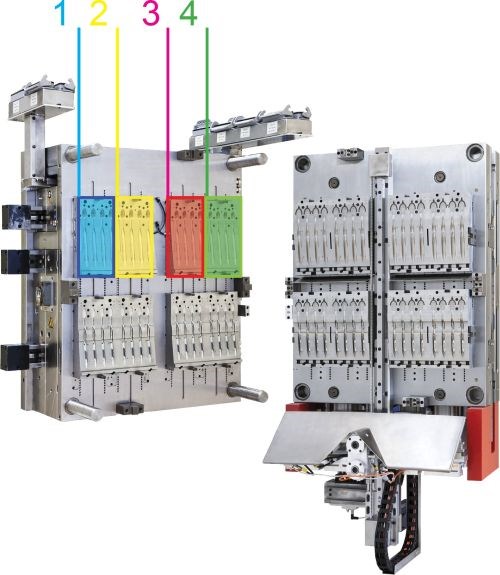

Seven-Component Mold

A seven-component mold technology allows toothbrushes to be made without time-consuming color changes. This complex multi-component mold can be a cost-effective solution for making identical products with different colors.

To make toothbrushes, moldmaker Zahoransky of Germany delivered a seven-component injection mold to Schiffer, a dental products company.

The 16-fold injection mold has two injection stations and one loading and removal station located outside of the mold. Two different materials in the same color are processed in the first station, while two different TPEs are used in the second station. One of these is injected in four different colors.

This seve-component technology allows toothbrushes to be made today without time-consuming color changes. Also, the costs of the expensive plastic material required when released during color change are now saved.

Building a seven-component mold was a major technical challenge both for the mold and toolmaker, considering that seven injection units had to be connected to the mold in the tightest of spaces. The availability of several material feeds, the different processing temperatures of the various materials and the close spacing between the different nozzles at the same cavity were also factors, which had to be taken into account.

Injection molding was done on a six-component machine from Engel. The seventh injection unit from Boy was integrated additionally in the production process.

Mold-Masters supplied the hot runner technology for this complex application, which involves a two-part soldered runner. Instead of having only straight channels, these runners have as many as three melt levels with gentle curves and turns. This means absolute design freedom owing to natural balancing, a uniform thermal profile and a comparatively low construction height. This technology allows two or more melt flow-ways to be integrated into a single runner. The design also allows six and more materials and colors in a single runner.

.jpg;maxWidth=300;quality=90)