Proprietary Systems and Expertise in Rubber Gives Roembke Mfg. and Design a Global Footprint

From the very beginning, Roembke Mfg. and Design has engineered and built molds for rubber products while also developing proprietary solutions for customers worldwide.

Explain Roembke’s history and expertise for building molds for rubber products.

Adam Shaal, Business Development Manager: Since opening our doors in 1977 we've always focused on building molds for rubber parts. In the beginning much of it was for automotive use like brake seals, wire harness connector seals, noise and vibration-dampening parts, with mostly wasteless, flashless transfer tooling for the automotive industry. Then in the mid-90s we started to build molds for liquid silicone rubber (LSR). We believe more than 40 years of experience with these types of molds sets us apart from many other moldmakers who started out in thermoplastics and then transitioned to LSR as many high consistency rubber molders began to transition to fully automatic LSR molding.

LSR is a very specialized product, and it takes a lot of experience to build a proper liquid silicone mold because the tolerances that are required to ensure you're building a flashless tool necessitates excellent, skilled employees and top-notch equipment. It's quite a bit different than your traditional plastic injection molds. For example, one of the biggest differences involves the flash point. With liquid silicone, if you have a mismatch or an air gap between your cavities of down to 0.0004 inch, you're going to get flash. Basically, if air can get out then the silicone can get out. Whereas with thermoplastics, you can be upwards of 0.001 inch before you'll see flash because of the material differences and because you're running at lower pressures with thermoplastic.

There are three different types of silicone. The first is room-temperature vulcanization (RTV) silicone that is used for caulking. RTV silicone cures very fast once it is exposed to air. The second level is high-consistency silicone, which is a pre-mixed formulation that cures in-mold with the application of pressure and temperature. It is often used for automotive engine components, extrusions, and parts that see heavy compression/decompression cycling. Then there is LSR, which is not premixed. Instead, at the molding machine you have two drums of material. One part contains a platinum catalyst that when mixed kicks off a chemical chain reaction causing the material to cure. Because of this formulation, LSR cures much faster than high-consistency silicone, which is an advantage, especially when cycle times are considered. With high-consistency silicone, you are typically looking at three to five minutes per cycle, but most LSR processing times are around 30 seconds. LSR is heavily used in the medical industry because, so far, no allergies have been indicated like they are with latex. In addition, LSR is processed using a closed system that doesn’t require direct material handling or open air exposure until after it has been fully cured.

How does Roembke ensure customers’ successes with molding tricky and complex rubber parts?

Shaal: We offer everything from cold-deck systems and quick prototype systems to full production molds and complete, automated turnkey molding cells.

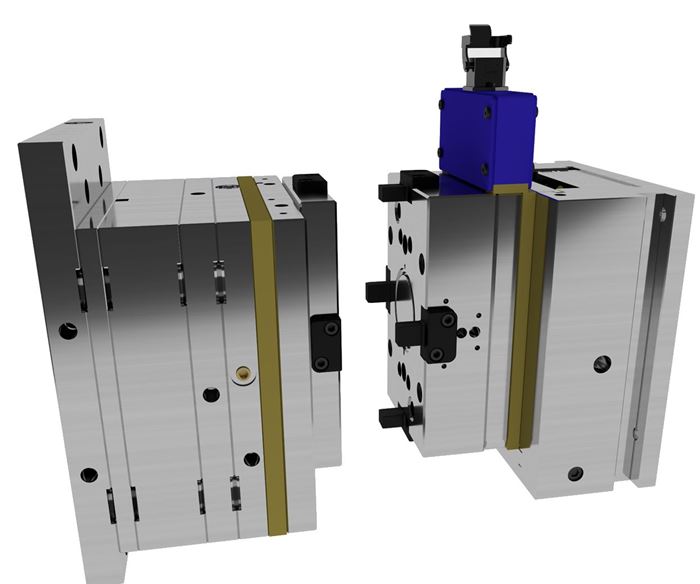

Our proprietary cold-deck system is the equivalent of a hot runner system in plastic. Our customers tell us our systems are much more balanced than other cold deck solutions and they are getting even material flows. But the other thing that sets us apart is we find that our cold decks have a more efficient cooling system. For example, if something happens and the power goes down in the plant, our cold decks can sit a long time before the material cures up. Given that we have the applications center, our guys must live with these systems every day, so we are constantly improving on our cold decks and we have an eye for maintenance and ease of use on these systems, which trickles down to cost savings for the customer.

We have full-time application and process development engineers where all they do is test molds that we've made, run trials and sample parts for customers, and debug turnkey molding cells. When you order a mold from us, we are going to run it and test it and get parts from it to ensure it works before we ship it to you.

Roembke has also developed a proprietary Quick Prototype System (QPS) that can be used for both LSR and HCR (high consistency rubber) materials. We prototype parts so that they are molded exactly as they would be in a production setting. This gives our customers the ability to take these parts and put them through true clinical trials or environmental testing versus having a part made from any available material just to get something into a customer’s hands. Oftentimes customers will request 5,000 or 10,000 sample parts to get them through their trials while we're building the production mold. We call it a quick prototype, but we build it the same way we would build a production mold using the same steel, same hardness to give them the best chance of success to develop their part.

There are risks when going from a lower grade prototype straight to production. These include parts not functioning due to dimensions. For example, the part may shrink differently between the two methods. One customer chose to have an aluminum prototype built elsewhere and then tried to go straight to production and the parts failed because the characteristics of the molded part from the cheaper prototype tool did not function the same in a true production setting. The part had excess flash. With our QPS, we can run trials and ensure the automation is going to work and that the parts are going to stick where they need to stick. We know the shrinkage is going to be there. Our customers can test different materials in the prototype tools, and they can take the cavity inserts out of the prototype mold and put them in a production mold and they will work exactly the same way.

Regarding the turnkey systems, we’re seeing them really taking hold in the market. In fact, our application center was filled with customers’ presses, so we recently added another 7,000 square feet to the building that is dedicated solely for constructing turnkey molding cells. That’s the biggest area we’re investing in today, with the second biggest focus being on our automation division.

Roembke can build several types of automated systems. It could be simple end-of-arm tooling to help remove parts from the mold. It could be complex automation with six-axis robots to not only remove the parts from the mold but then maybe do secondary operations at the machine. We also develop downstream automation. For example, a customer might be taking the molded parts and sending them through some form of a secondary operation like adding a slit feature. It could require inspection with cameras, parts assembly—there is a wide range of options.

What is Roembke doing to leverage its expertise in molds and molding rubber products?

Shaal: We partner with the material suppliers and press manufacturers. At trade shows we typically have one or more of our molds running demonstrations in their booths. They also provide us products to test before it becomes commercialized because they can do real-world testing in a true production environment to see how the material is going to react in different situations. But they also want to learn if it's moldable, how clean it molds, how efficient it molds and things of that nature. They provide us with a sample kit and we run parts for them and provide feedback. It’s the same thing with press manufacturers. For example, when Engel was developing its X-Melt Technology for LSR, they conducted trials with us at our shop to see how it would work. It's a big advantage for us because many times that's where customers start in rubber molding, either with the material or the press.

We have also entered into the training process, and years ago we partnered with RJG Inc. RJG always had their systematic molding for thermoplastic, but they wanted to develop a class focused on liquid silicone. They spent several weeks at our facility when we were doing multiple studies experimenting with different scenarios of LSR molding and we supported them as they developed their training program for LSR. That class happens at our facility at least twice a year now.

Related Content

Developments in High-Speed Machining Technology

There have been many exciting developments in high-speed machining relative to machining centers and controls, tooling and CAD/CAM systems.

Read MoreTechnology Roundup: New/Improved Technologies You Don't Want to Miss

With all the technology joining the market, moldmaking is a versatile, ever-evolving industry. As such, this technology roundup has no specific theme — it features a variety of products for applications and solutions across the industry.

Read MoreCAM Automation Increases Mold Production, Quality

Mold builder switches CAM software package after 20 years to take advantage of innovative programming strategies that reduce mold machining programming and processing times.

Read MoreHow to Automate Process and Design

Moldmakers can improve their operations and stop wasting time by taking these six steps for process and design automation.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

_300x250 1.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)