Popular Posts: April 2020

These popular blog posts from April 2020 feature a topic that has been on everyone’s mind in the past month: coronavirus and how the moldmaking industry is adapting to this global crisis.

The number one topic that has been on everyone’s minds for the past month was the coronavirus. So it comes as no surprise that some of our most read blog posts from the month of April reflect that. As the moldmaking industry has been adapting to this global crisis, we here at MoldMaking Technology have been covering shops and companies each week to see how they’ve been handling the situations, whether it be rapid production of much-needed personal protection gear for healthcare workers on the front lines, changing processes to prevent more spread of the virus and keeping the workplace safe and healthy for workers, or even keeping up company moral in these trying times.

Take a moment to read up on these stories, and make sure to visit Gardner Business Media’s complete log of COVID-19 coverage to see how the entire manufacturing industry, not just moldmaking, is handling this global impact.

Moldmaker and Steel Supplier Stand and Deliver during Coronavirus Outbreak

Bill Berry, President and Owner of Die-Tech & Engineering (DTE) in Wyoming, Michigan, took on a complex die project from in Minneapolis, Minnesota, for a component that is critical to current ventilator production. Die-Tech and Engineering and Twin Cities Die Casting are just two of the many American manufacturers coming together to help our nation through the COVID-19 crisis. Die Tech and Twin Cities Die Casting are working to help Ventec, a leading supplier of ventilators, to quickly ramp up production. Die-Tech is currently working on tooling for 10 more parts.

Read the complete article here.

Answering the Call: Plastics

Right now, we are in the middle of the COVID-19 pandemic, awaiting a massive stimulus bill, digesting news about the virus daily, learning about states in lockdown, and experiencing a declining stock market. I have been in the industry for 25 years. For the last 12 years I work for R&D/Leverage (Lee’s Summit, Missouri) as a global marketing director for the U.S. headquarters and UK facility. Over the years I have admired the many executives in the plastics industry I have worked for and have learned a lot from colleagues and peers as this industry has grown and changed.

Read the complete article here.

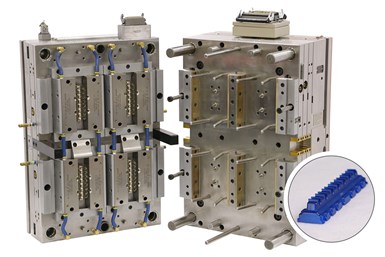

8 Ways to Increase Mold Life

Tool life is key to a company’s bottom line and profitability. With the design and building stages complete, it is time to set the mold in the press and develop a process. Here are key press settings and essential preventative maintenance steps to improve mold life.

Read the complete article here.

Related Content

Exploring ISO 9000 - Part 16 Control of Quality Records

A Series of International Standards for Quality Management and Quality Assurance. We begin 2022 with a review of Clause 4.16 Control of Quality Records.

Read MoreR&D Tax Credit Refresher

A list of the top 10 moldmaking activities frequently performed through daily business that qualifies for an R&D tax credit.

Read MoreFlowmeter Enables Accurate Water Volume Measurement, Regulation

Hasco’s flowmeter, which can be installed anywhere in the direction of flow, aids moldmakers in rapid and easy flow rate readings on injection molds.

Read MoreVIDEO: What You Need to Know about the R&D Tax Credit Today

A team member from Strike Tax Advisory reviews the tax changes that are impacting the R&D credits for mold builders.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

_300x250 4.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)