A Solution for Spindle Repair

Getting a spindle repaired or replaced to get it back up and running is critical in any shop, but that is often not a simple process. Take a look at this spindle repair shop's solution.

We all know that it is critical to get a spindle repaired or replaced to get it back up and running, but it is often a challenge. According to David Kirkpatrick, president of Superior Spindle Service of Taylor, Michigan, there are several components and systems related to spindles that could be the cause of spindle failures or at least contribute to them. For example, faulty lubrication lines and control issues that actuate the draw bar and encoder issues. Many of these causes can go undetected. Kirkpatrick believes that after a spindle is damaged a detailed failure analysis report that includes data accumulated thorough comprehensive inspection and testing is a must. Let's read how he breaks it down.

Kirkpatrick says that a comprehensive failure analysis report should clearly show when the real cause of failure is not the spindle itself, but something related to the motor, bearings, gages or even improper spindle mounting. Generally speaking, failure analysis amounts to the process of collecting and analyzing data to help determine the true cause of a failure. The goal is to recommend corrective actions that will help avoid future failures.

The critical phase of an in-depth failure analysis process is the report that documents findings and includes recommendations for corrective actions. Kirkpatrick recommends an intensive program that encompasses not only attention to the spindle, but also motors, bearings, air purge and other associated components. His company treats failure analysis as a primary service function.

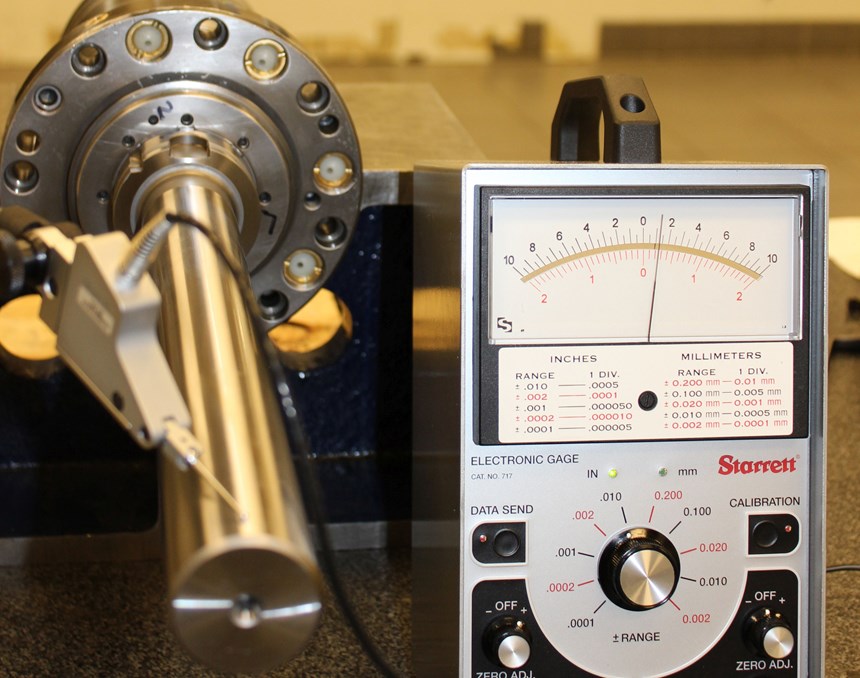

During the tear down procedure, every part is inspected to identify why and how the spindle failed. Once the equipment has been thoroughly cleaned, every part of the spindle’s geometry is examined, referencing OEM standards for dimensions and concentricity. Every step of this process is photographed and documented, and included with all findings in a comprehensive failure analysis report, along with specific recommendations on how similar failures can be avoided and spindle life can be extended.

To provide another level of failure analysis, suppliers that provide tooling draw bar systems and other third-party experts can also be called upon to complement the failure analysis effort by substantiating report findings as they pertains to their product.

A firsthand view of the CNC center on which the spindle is running is also recommnended. This can reveal setup and alignment problems, improper spindle mounting, motor-related problems and controller malfunctions. Kirkpatrick also noters believes that when a spindle is underperforming in a specific application, it is possible to improve on performance through spindle design modifications such as spindle metallurgy or shape.

Related Content

-

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

-

The Secrets to Hard Milling Success

The Secrets to Hard Milling Success

-

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

.jpg;maxWidth=300;quality=90)