News and Reviews from Industry Organizations, August 2018

News and reviews from the American Mold Builders Association (AMBA), the Mold Technologies Division of The Society of Plastics Engineers (SPEMTD) and Canadian Association of Mold Makers (CAMM).

Canadian Association of Mold Makers (CAMM)

Members of CAMM recently participated in a civic project that required their metalworking skills on a more artful level than even moldmaking requires. “Our Rotary Club is 100 years old this year,” Janet Kelly, Chair of the Rotary Club of Windsor (1918) Centennial Legacy Projects Committee, says. “The City of Windsor has a five-year plan to develop pieces of the river front and asked us if we would like to work with them to develop the piece of land just west of the Festival Plaza,” she says.

Enter CAMM, whose members were asked to partner with Rotary by machining and assembling five sculptures (two large and three smaller versions of the same design), which were designed by Windsor’s landscape architect Stefan Fediuk out of aluminum. “CAMM Chair Jonathan Azzopardi of Laval International and Mike Hicks of DMS (Canada) Ltd. were instrumental in bringing fellow CAMM members, including Cavalier Tool and Mfg., Omega Tool Corp., Windsor Mold Group and Integrity Tool and Mold, into the project. CAMM stepped up largely to build the sculptures for us and helped us with some design modifications because they had better ideas than we did,” Kelly says. “They’re very creative. The sculptures needed to be cut, polished and coated—it was quite a process.”

On May 29, 2018, Rotarians and CAMM members alike gathered at the Centennial Plaza to officially open it to the public. Visitors to the plaza’s main entrances were greeted by the large-sized gateway markers that feature shell-shaped gears meant to communicate that the Rotary Club’s service to the community is eternally ongoing, according to Kelly. These, and the three smaller versions placed at other entrances, welcome visitors in 40 languages.

The Mold Technologies Division of the Society of Plastics Engineers

The Mold Technologies Division of the Society of Plastics Engineers (SPE) honored Charles (Chuck) Klingler, vice president of Janler Corp. in Chicago, Illinois, as Mold Maker of the Year. The award was presented during Amerimold 2018 in Novi, Michigan.

Each year, the SPE Division recognizes individuals who have supported and advanced the moldmaking industry by making contributions above and beyond the norm. Both a Mold Maker of the Year award and a Mold Designer of the Year award are presented along with a $500 honorarium that is donated to the trade-related education program of the honorees’ choosing. Lake Park High School in Chicago will be the beneficiary of Chuck’s check from SPE. SPE named James Baldwin of Western Carolina Tool and Mold in Horseshoe, North Carolina, the SPE Mold Designer of the Year. His grant money will go to benefit the Blue Ridge Community College Educational Foundation for its mold design and injection molding programs.

American Mold Builders Association (AMBA)

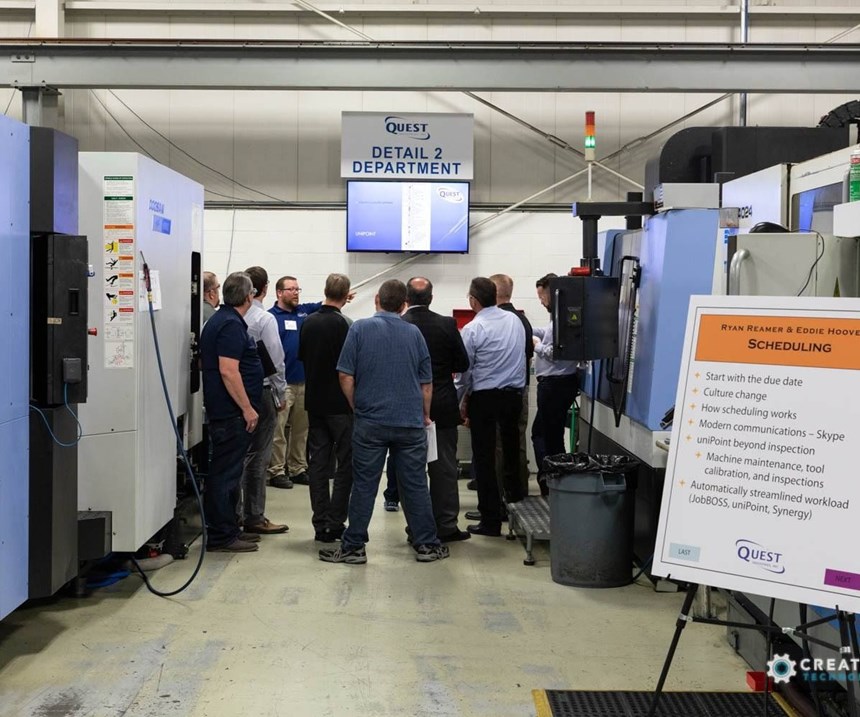

The AMBA supplemented activities that were offered during Amerimold week by hosting an educational tour of Quest Industries in Lapeer, Michigan. Attendees were treated to an informative and in-depth view of how the company uses its enterprise resource planning (ERP) system—backward—to optimize the way it schedules and moves work through the shop. That’s right. They plan jobs by looking at the delivery date first and then working backward. This strategy did not happen out of the gate in 2006 when Quest purchased its JobBoss ERP software, but today, JobBoss is its primary ERP system with the addition of Unipoint quality management software. As discussed in MoldMaking Technology’s May issue feature, Exact Synergy Enterprise (ESE) is the glue that ties all of the information together so that detailed information about every job, from start to finish, is always accessible to anyone who needs it.

Additionally, the AMBA conducted a Tech Talk session at Amerimold that presented workforce development strategies for closing the skills gap. Representatives from four AMBA member companies participated: Tim Myers with Century Die Co., Britteny Willis with Paragon D&E, Kylee Carbone with Westminster Tool and Tom Barr with TK Mold and Engineering. The representatives from these companies shared how they are creating apprenticeship and training programs, are partnering with area schools, are developing software training and are investing in equipment or software. These companies discussed how they are hosting open houses, are developing videos and other promotional materials, and how they are are participating in career fairs and industry advocacy at government and community levels. .

Related Content

Making Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreMold Builder Uses Counter-Intuitive Approach for Mold Challenges

Matrix Tool Inc. answers customers’ hard questions with creative solutions for cavity spacing, tool sizing, runner layout and melt delivery that reveal the benefits of running in a smaller press size at lower cavitation but higher yield.

Read MoreLeading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More_970x90 4.png;maxWidth=970;quality=90)