How to Set Accurate Manifold Preventive-Maintenance Frequencies, Part 2

The key to developing accurate and timely PM work instructions is understanding the impact of environmental factors on manifold performance.

The June issue’s article on manifolds and preventive maintenance (PM) presented opinions on the frequency of hot runner manifold disassembly, cleaning and repair from the manifold manufacturer, a manifold cleaning and repairing company and the molders running these systems.

“Environmental factors” were mentioned in the article, as each party noted difficulties with identifying and controlling critical factors, their influence on manifold performance and the resultant costs when they failed to identify and control those factors in an accurate and timely manner.

Understanding environmental factors and their potential impact on performance is key to developing accurate and timely PM work instructions, which technicians perform at optimal, scheduled times instead of waiting until the manifold starts causing issues or exhibits diminished performance. Diminished performance is a reduction in cavitation that occurs because the cavities freeze off, or they are lost to part quality, heater or thermocouple issues, seal failure or other mechanical problems.

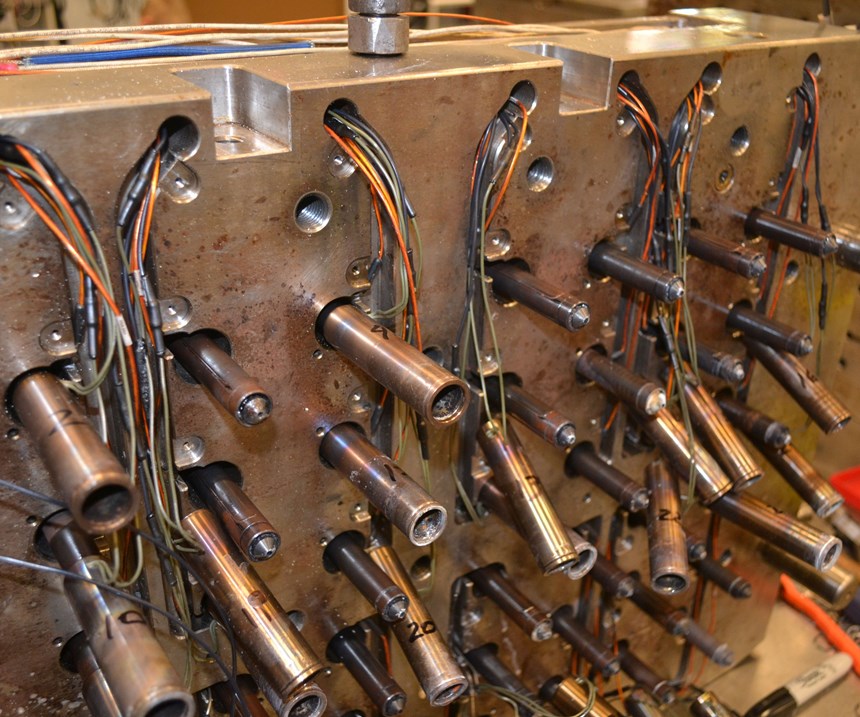

The goal of PM is to maintain the hot runner system in a way that is cost-effective while ensuring that it runs consistently and reliably, which maximizes performance (in terms of the part quality, cavitation and cycle time) and manifold component life (in terms of the heaters, thermocouples, valve pins, nozzles and tips). The difficulty with achieving this goal is in a molder’s understanding of manifold characteristics and the impact of environmental factors.

Facing the Factors

Here are three common environmental factors that a molder must understand, monitor and control when running and maintaining a hot runner system. This information will provide the necessary data so that molders can develop accurate and timely PM plans.

Resin and Processing Issues

Degraded plastic and contamination in the melt stream is the main culprit of a total manifold teardown. The result is black or brown specs or streaks in the molded part, which requires a hot aluminum-oxide sand bath (such as those that Procedyne offers) to remove the residue from the manifold channels completely. The manifold must be removed from the mold frame and completely stripped of components before being inserted into the sand bath. Heat-sensitive resins, incorrect shot size (or residence time), color changes, improper start-up or shut-down procedures cause many contamination issues.

Unfortunately, even the necessary in-house equipment and tools will not guarantee success without better troubleshooting for the root cause. Some resins are simply difficult to process, which can cause problems that require the expertise of a resin supplier. For example, a medical company ran an ABS with a white-colorant titanium dioxide (TiO2) that stuck to the manifold’s channel walls and required gun drilling because a hot sand bath would not remove all of the residue. On top of that, the sticking did not occur after a specific number of cycles. It ranged between 350,000 and 2,000,000 cycles, making a solid PM frequency difficult. The company’s solution was to buy a second manifold, so operators could quickly swap out the failed one as necessary. This strategy helped solve some production issues, but scheduling would still back up. The company believed that incorrect TiO2 or colorant levels caused the inconsistency, so the company began comparing the production data (press, run dates and cycles) with the resin lots. This data made it possible to have more meaningful conversations with the resin supplier.

Abrasive and corrosive resins will wear out nozzles, valve tips, valve bushings and gate inserts. As this tooling wears, residue invades piston cups and manifold bushings. As nozzle tips wear, processors are forced to crank up the nozzle temperatures to compensate, which further compounds flash and burned material.

Operators must perform color changes according to manufacturer instructions and use maintenance manuals for any required tools or fixtures. Technicians should use nozzle-tip insulators and high-temperature purging compounds when switching from a dark to a light color.

Even the necessary in-house equipment and tools will not guarantee success without better troubleshooting for the root cause.

Production Issues

Preventing manifolds from fully expanding during start-up is number one on the leak list or is the root cause of total encapsulation. Many manifolds and components are designed to be completely dependent on an appropriate soak time to fully seal the rear of the nozzle to the manifold, and the nozzle’s front seal (which is radial) to the cavity gate. However, production requirements continue to push the “hurry-and-get-it-running” mandate when molders should use the manufacturer’s recommended procedures or create their own.

Other mistakes, such as shutting the water off and leaving heaters on over a weekend, will quickly degrade the plastic in the manifold as well as critical seals and o-rings. This also will cook applied lubricants in piston cups and other valve-gated components. Another bad practice is turning the water on after the mold has reached the processing temperature. This does not speed the start-up process.

A better idea is to heat the manifold before the nozzles and bridge. This allows the manifold ports to slide more easily across the rear of the nozzles during expansion, minimizing the drag between these two components. Operators should perform the reverse when shutting down the manifold. This approach—because nozzles heat up quicker than manifolds—reduces the chance of burned material, as the operator waits for the manifold to reach processing temperature.

Another big concern is the presence of contaminated resins in silos, conveying lines, gaylords, hoppers, hoses, dryers, grinders and any other resin paths. Proper cleaning before the plastic hits the mold is essential because these resins stick and clog manifold flow passages, nozzles and nozzle tips.

Controllers, electrical connectors and cables also need a maintenance plan for periodic inspections and testing, a well as a designated storage area.

A better idea is to heat the manifold before the nozzles and bridge. This allows the manifold ports to slide more easily across the rear of the nozzles during expansion, minimizing the drag between these two components.

Maintenance Issues

Operators must clean and inspect moving parts for wear, damage and lubrication levels, especially when the tooling is close tolerance, and operating in unclean conditions, with high heat and under pressure. Otherwise, small scuffs turn into minor leaks that result in major leaks. Improper removal, cleaning and reassembly of delicate tooling and critical seals will influence manifold performance and, in some cases, void the manufacturer’s warranty. It is imperative for repair technicians to possess a working knowledge of the impact of heat expansion and residue levels on preload, seals, valve-pin function and stack height. Electrical knowledge is also key for proper heater and thermocouple inspection, testing, removal and installation.

Valve-gated systems that are air-based, oil-based or mechanically actuated add another level of complexity for technicians even though they all contain the same basic parts (valve pins, valve-pin bushings, cannisters or piston housings, pistons and a variety of internal and external seals). A lack of proper lubrication, rough handling of components during a PM sweep or incorrect assembly will create dings, scratches or burrs that cause wear.

Technicians often overlook the cleaning of air lines through the mold base and small inlet holes that actuate the valve pistons, which affects operating pressures. Valve-pin actuation pressure reduces when these lines and holes get clogged from dirty air or off-gas weeping. This results in uneven and sluggish movement from one cavity to another, causing uneven fill, shorts and long gates.

Long gate is the number-two culprit for manifold disassembly and repair (see the chart from the June issue). Fixed-gate systems also suffer from long gate but for different reasons. Fixed gates rely on a proper nozzle-tip configuration a relative distance to the gate and land area. Both systems require proper cooling and verification using timely flow-restriction analysis with a baseline water pressure versus a known gallons-per-minute (GPM) figure on all plates, cavities and cavity-gate inserts.

From a maintenance standpoint, technicians need to concentrate on more thoroughly controlling their part of the manifold-performance equation to reduce the amount and impact of environmental variables. This strategy will yield more accurate PM frequencies and instructions, improving manifold performance and defect consistency.

About the Contributor

Steve Johnson

Steve Johnson is president of MoldTrax, which provides specialized course work, hands-on bench training, maintenance software, maintenance products, toolroom design and maintenance-efficiency auditing.

Related Content

How to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

Read MoreHow to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MorePortable Low-Heat, Non-Arcing Resistance Welder for Mold Repair

Rocklin’s user-friendly MoldMender Micro Welder delivers simple and cost-effective localized repair in-house with precision and versatility, enhancing mold and die durability and reducing disassembly and downtime.

Read MoreRead Next

How to Set Accurate Manifold Preventive Maintenance Frequencies

Clearly setting accurate manifold preventive maintenance frequencies requires reliable comparative data on how a hot runner system performs over time.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)