Encoders, Flow Regulators and Stabilizing Cylinders Make Mold Spotting More Efficient, Precise and Cost-Effective

For complex molds, Cavalier Tool & Manufacturing counts its advanced spotting press among its most valued pieces of shop-floor equipment.

Cavalier Tool & Manufacturing Ltd. of Windsor, Ontario, Canada builds more than 200 mid-to-large-size molds annually, the majority of which are complex in their design. Because of this, Cavalier believes using a spotting press to fit molds is a critical step in its moldmaking process, and the most efficient and cost-effective way to deliver precision, production-ready tools to its customers.

“If we built molds for something like a pizza tray or a pie plate that is very small, very flat and very easy to make, my dependency upon spotting would be very low,” Brian Bendig, president, says. “I could almost always build that kind of mold and never have to spot it. But Cavalier builds large, complex molds with deep cavities, angles and shutoffs, and we would have a heck of a time building them without spotting them.”

Two years ago, Bendig and his team decided it was time to upgrade the company’s spotting press capabilities by purchasing a new Millutensil MIL-306 500-ton spotting press. The company’s old spotting press also has a 500-ton capacity, but Bendig says it was cumbersome to use, not as precise and required many more steps in the process to use. “This Millutensil is the sniper rifle of spotting presses,” Tim Galbraith, sales manager, asserts. Bendig agrees.

Increased Efficiency and Accuracy

Both Bendig and Galbraith credit the accuracy and efficiency of today’s CNC machining centers for making mold assembly and fitting processes easier. “I remember the days when we used to put a tool into the spotting press and spend a week spotting a mold down because we were not as accurate with our machining as we are today,” Galbraith says. He describes how moldmakers would use masking tape to tape their wrists, ankles and around their necks to keep the grinding dust from getting inside their clothing, there was that much spotting and grinding to be done. “But now, we are at the point where we are just tickling the mold, and it takes only three, or maybe two, hours to spot it.”

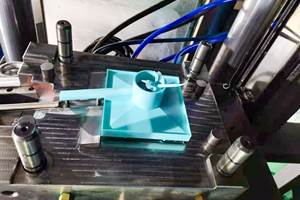

Bendig adds that while Cavalier’s Millutensil, which features a table size of 138 by 94 inches, has a 500-ton capacity, today there is rarely a need to use such high clamping pressures to spot molds. “We sometimes only spot with 50 tons of clamp pressure — or even just the weight of the mold itself — because we can cut so accurately, and we don't want to force the mold together like in the past. We just want to identify what’s high and grind that high spot off and fit it again, as needed. It’s a much quicker method of getting to the finish line, and it’s more accurate.”

With the Millutensil, setting up a mold is straightforward.

Helping Cavalier reach that finish line faster and more accurately is the fact that the Millutensil features encoders on each of its four tie bars that actively gauge the flatness and parallelism of the mold halves throughout the spotting process. “In a perfect world, when you're spotting, you need perfect, exact parallelism between the upper and the lower halves of the mold. The more exact you are, the more likely you are to spot properly. The Millutensil’s encoders, in the event you were to cock the plate, would identify the problem, automatically default to a soft ‘hold’ mode and sound an alarm to alert the operator before any damage can occur,” Bendig says. In addition, flow regulators and balance units at the top of the press ensure that it lowers exactly parallel, and there are large copper bushings that help prevent the crown from tipping or turning. “That’s how we are able to make it go up and down very accurately.”

The Millutensil’s design simplifies mold setup as well, Bendig adds. “In a real small press, you have four guides and one cylinder in the middle that pushes down, but imagine you have a mold that is very long, like your kitchen table. Where do you put the cylinders to be accurate? Do you put them on the center of the table? Do you split the difference with one on the outside and one on the edge? With the Millutensil, setting up a mold is straightforward. There’s no guessing or risk-taking because this is a four-post, down-acting press, meaning it's got four cylinders that cover greater than 60 percent of the usable platen, and they are spaced out evenly on the platen so that you have equal clamping forces going down.”

Beatrice Just, vice president at Millutensil SRL (Milan, Italy), points out that spotting operations are intuitively controlled using the system’s Siemens Touch-Panel tablet and diagnostics program, which provides the operator with a specific pictogram of every movement the press makes during the spotting process. If something should malfunction, the relevant point is displayed on the specific page within the diagnostics program for easy access to a solution. “This allows for down time minimization, quick troubleshooting and reduction of service costs, especially after the warranty period,” she says.

“We don’t need to run a trial cycle in a plastics press to look for flash because we have the Millutensil spotting press that ensures our molds are fitted perfectly.”

Bendig adds, “The benefit of the control is more accuracy and pressure. You can very accurately set the pressure, where an old press operated using a valve control that you would rotate to generate either more or less hydraulic pressure on the clamp force.”

Cavalier tracks a variety of metrics to help keep operations on schedule. One of those metrics involves its goal to get every mold to T-zero (functional tool trial) and have no flash. The Millutensil is key to meeting that objective. “If we go to T-zero and we see flash, we want to know what went wrong,” Galbraith says. “We don’t need to run a trial cycle in a plastics press to look for flash because we have the Millutensil spotting press that ensures our molds are fitted perfectly.”

Safer and More Ergonomic Operation

Ergonomically, the Millutensil has made an impact on how spotting is done at Cavalier. “Our old spotting press was as big as a dinosaur, and it was surface mounted, so we had to go up several steps to climb onto the platen and literally get into the press to set molds up. Sometimes it felt like we were spotting parts for Noah’s Ark,” Galbraith says. Additionally, the press was not parallel, which, combined with clamping forces, often led to crushed vents that needed to be redressed. “It was difficult spotting properly using an old and tired press.”

Cavalier’s Millutensil is installed at floor level so operators can simply walk up to it and work on it. “If they need tools from their toolboxes, there is no need to go up and down stairs to get them. It is ergonomically more efficient just from that standpoint,” Galbraith says. “The other benefit is you can drive a lift truck up and place the mold into the center of the platen, then roll it into the press to be spotted, which is really convenient,” Bendig adds.

Just says that Millutensil presses are designed with the spotting crew in mind. On the MIL-306, the upper platen features the capability of flipping 100 degrees (standard), 150 degrees and 180 degrees, helping to avoid stressful maneuvers during the spotting process by making the molds easily accessible. In addition, the lower platen slides in and out of the press, giving workers better ergonomic access to both halves of the mold in the same work space.

With ergonomics comes safety, and Just says the patented SITEMA safety device is unique to Millutensil’s presses. Differing from the multi-hole or toothed bar system commonly found on other spotting presses, this anti-fall safety device is externally installed on the right and left side of the upper floor of the press and mechanically wedged in a locked position, preventing the press’ upper platen from falling if power is ever lost.

What takes other shops 100 hours to do, we can do it in 50 or 70 hours in our Millutensil, so there's not only a time advantage, there's a cost advantage.

Bendig says that, unfortunately, spotting presses are one of the last things shops look at because it is a large capital investment for a non-sexy operation. “It goes up and down. It's not five-axis, and it doesn't have a robot,” he says. “It's got some disco lights, but that's one of the cool things we have here.”

Sharing the Press Benefits

The Millutensil may be the sniper rifle of spotting presses, but Galbraith and Bendig agree that to make the most of its capabilities, it is important to have sniper-quality spotters on the Cavalier team to achieve that perfect fit every time. The company has two employees who do nothing but mold spotting. In addition, it also has a company that works within its facility and provides spotting services for Cavalier and other mold builders in the area. “We insource work from no less than ten of our competitors every month because we are achieving much better results with the Millutensil than an old press can achieve,” Bendig says. “Our highly-skilled spotters have good artistic talent and experience to know how to grind off just enough. What takes other shops 100 hours to do, we can do it in 50 or 70 hours in our Millutensil, so there's not only a time advantage, there's a cost advantage.”

Galbraith points out that shops often have more than one spotting press because of the time it takes to spot one mold in an older press. The modern, advanced Millutensil, which is in operation 24/7, handles all the molds from Cavalier and those from other shops in the region. “When customers come in and they see our spotting press, they make mental checkmarks, so we do use it as a sales tool,” he says.

“At Cavalier, we recognized the long-range benefits of having a good, modern and robust piece of spotting equipment and what it brings to the table as far as getting T-zero parts flash-free, getting crisper parting lines, not crushing vents, no rolling edges and so on,” Bendig says. “At the end of the day, the molds run faster, and there’s also less tool runout.” He adds that it is a real art to be able to do spotting efficiently and effectively. “The Millutensil spotting press helps take the art of spotting to a higher level of perfection.”

Related Content

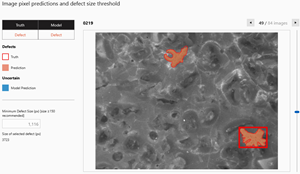

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

Read MoreMoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

Read MoreEvaluating Metal Powders for Conformally Cooled Mold Inserts

Mechanical properties and design software techniques reveal the benefits of a modified high thermal conductivity metal powder for 3D printing in moldmaking.

Read MoreThree Advances in Vision Measuring Technology for Moldmaking

Next-generation metrology solutions are streamlining shopfloor automation and quality control for mold builders.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

_300x250 1.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)