Considerations for AM Powder for Tooling

The start of any good product is the raw material, and that includes additive manufacturing powder for tooling.

Materials development in additive manufacturing (AM) is a growth area and one that mold builders should keep their eyes on as they consider offering alternate mold manufacturing solutions for their customers. The start of any good product is the raw material, and that includes AM powder for tooling.

The five material aspects to consider for AM powder for tooling are chemical composition, particle size distribution, shape, flowability and density.

The key to AM is determining the most appropriate path of production for the part. Once you design the part and determine the method of manufacturing, material selection is the next step. The three elements of a quality additively produced part are powder, parameters and the system. Let’s focus on the powder. The five material aspects to consider for AM powder for tooling are:

- Chemical composition

- Particle size distribution

- Particle shape

- Particle flowability

- Particle density

Changing any of these five powder aspects will impact the quality of the part you are building with AM, and each one varies across the available AM technologies. For example, particle size distribution for powder-based fusion technology requires 15 to 45 microns compared to direct energy deposition (DED) which can be 50 to 150 microns. As a result, some mold material suppliers have invested in a lot of R&D to study AM powder material and to ensure their materials meet industry standards and customer requirements.

One such AM powder is tailored for tooling and was developed with the appropriate corrosion and wear resistance properties as well as polishability. This material is both a traditional tool steel and AM powder with the same properties. Its microstructure, hardness (36-50 HRC, achieved by an aging treatment in the temperature range 425-600°C (790-1110°F) and mechanical properties are similar. Its main application is conformal-cooled inserts to reduce cycle times due to the high demand, short-run series and ever-increasing need for shorter lead times. Current development also includes a powder for high-pressure die casting.

The key is to get data before you build.

If a mold shop is ready to select an AM powder on its own or if the shop is working with an AM partner, inspection reports can verify powder characteristics. For example, for particle size distribution, use a laser to examine a sample of the powder; for particle shape, use a microscope to determine how spherical the powder is as well as the aspect ratio, and for flowability, measure the number of seconds it takes to flow 50 grams of the powder. These are all industry standards used to identify the quality of a powder. A mold builder should also be aware of the need to control for humidity and oxygen content during any handling processes to ensure powder quality.

Simulations can also prove the effectiveness of AM powder for tooling, such as finite element analysis (FEA) for structure and computational fluid dynamics (CFD) for flow and plastic component. A shop itself, or with its AM partner, can take the AM tooling powder data sheet (chemical composition and mechanical properties) and enter the information into simulation software to simulate the performance of the injection process. The key is to get data before you build.

About the Author

Sami Arsan, P. Eng, PMP, CAM-F, is Vice President, Advanced and Additive Manufacturing Technologies in North America for the Voestalpine Additive Manufacturing Centers.

For More Information

800-665-8335 / sami.arsan@voestalpine.com / voestalpine.com/additive / voestalpine.com/hpm/usa

Related Content

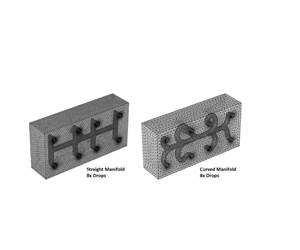

Guidelines for Advanced Hot Runner Manifold Channel Design

Recent simulation research highlights the difference between a drilled, straight manifold channel design and a curved channel design produced via additive manufacturing.

Read MoreVariable Density-Coated Tool Steel for High-Wear Molds

A mold builder can have an abundance of venting and fully dense solid areas in steel by using variable density sintering to eliminate gas trap defects in high-wear molds.

Read MoreMMT Chats: California Mold Builder Discusses the Difficulties with Silicone Molding and the Power of the Magic 8 Ball

MoldMaking Technology Editorial Director Christina Fuges sits down with M.R. Mold President and Owner, Rick Finnie, to discuss how he began his moldmaking career, M.R. Mold's LSR Education, and the struggles of working with silicone. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreVIDEO: What Does Integrated Predictive Modeling Mean to Moldmaking

Although conformal cooling is not a new concept, new technologies have made it a very hot topic, including predictive engineering models and 3D printing. Learn about a new conformal cooling process and algorithm and what it reveals about hot spots and conformal cooling design.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

_300x250 4.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)