Battling Robots Continue to Attract Youth to STEM-Based Learning

Heidenhain was a sponsor of the recent National Robotics League’s national competition “where education and mayhem meet.”

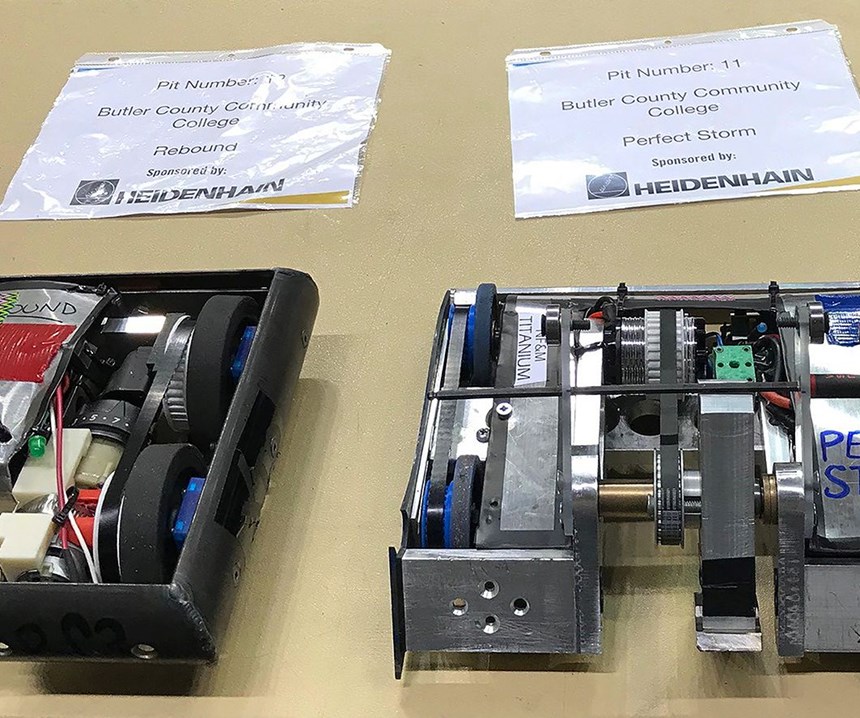

For generations, robots have fascinated humankind so it is no wonder that battling robots are magnets for youth and industry “veterans” today. Heidenhain was a sponsor of a recent battle bots competition put on by the National Robotics League (NRL) at the California University of Pennsylvania on May 17-18.

I would not have known about Heidenhain’s involvement if I had not bumped into Gisbert Ledvon, TNC Business Development Manager, at DMG MORI Innovation Days (DMG MORI has Heidenhain controls on some of their machines). He was leaving that day to attend the competition and mentioned it to me, so I asked him to let me know how it went when he got back.

“We believe it is so important to support our country’s youth who are involved with engineering and manufacturing,” he says. “It is quite impressive to watch their intelligence and machine skills put to use to create ultimate robots that dole out damage yet withstand destruction from opponents.”

Heidenhain sponsored the Team PIT area, with Ledvon and other company representatives assisting with pre-evaluation of high school students from 58 teams who presented engineering documentation on their respective robot contenders. “I had the privilege to pre-interview two of the teams prior to the competition,” Ledvon says. “The first team had six girls and two of them will pursue a career in manufacturing, specifically mechanical and electrical engineering. The others will go into law and human resources. They all felt that this project helped the better to understand how things are made and how a team has to work together in order to achieved a goal even though every person has different skills. Some of the girls worked on turning and milling machines or created 3D models for components to be built on a 3D printer. Others had the task of documenting the project and keeping the team on track. Each team had to provide a detailed report on how the entire project got started all the way to final testing in battle.”

He says the second team was composed of three girls and one boy. The young man told Ledvon that he is considering a career working in manufacturing and became interested in participating in the competition by a relative who works as a welder.

“I asked both teams if they now understand that things have to be made and ‘don’t just come from Amazon.com,’” he says. “They all laughed but continued in the conversation and we discussed how important it is that a country like the United States continues to build up these manufacturing skills so that we can make our airplanes, medical devices, cars, etc., here and not rely on other countries to provide us with the technology. They all agreed and felt that this project and competition really opened their eyes about how complex it is to build something like a robot from scratch.”

Beyond Robots

Heidenhain is actively supporting the U.S. manufacturing education effort through a school support program where the company provides special pricing for CNC simulators at schools or for apprentice programs in shops. “Our latest success story is the Community College of Denver whose Advanced Manufacturing Center (AMC) is now a Heidenhain-certified training partner (ATP) for the state of Colorado. To become a Heidenhain ATP, CCD staff completed several rounds of advanced training on the five-axis Heidenhain TNC machine controls and successfully passed an extensive exam. There are multiple Heidenhain TNC controls in operation at the AMC, and student classes are currently being offered there from basic to advanced control programming and training.

“Heidenhain now also offers a training program called HIT, which stands for Heidenhain interactive training. HIT works on the Moodle learning platform used by many schools and universities,” Ledvon says. “This tool works in the cloud and can be used free for 90 days. A professional license, including a virtual classroom of 20 students, is less than $1,000 for 24 months.

“Of course, we always offer free workshops for teachers and trainers who want to learn more about five-axis machining technology at our Training Academy or at the Community College of Denver.

Related Content

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreFrom Injection Mold Venting to Runnerless Micro Molds: MMT's Top-Viewed June Content

The MoldMaking Technology team has compiled a list of the top-viewed June content based on analytics. This month, we covered an array of topics including injection mold venting, business strategies and runnerless micro molds. Take a look at what you might have missed!

Read MoreSteps for Determining Better Mold Prices

Improving your mold pricing requires a deeper understanding of your business.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)