For more than 25 years, W. Fassnacht Werkzeug- und Formenbau has been providing high-quality molds to a diverse range of industries. Recently, the Swabian company was named Germany’s Toolmaker of the Year 2017 because it believes in doing things in a small but smart way.

The company has sustained healthy growth since its inception in 1990. A continuously growing customer base left company founder Wolfgang Fassnacht and his team of 20 workers at a crossroads about eight years ago: Should they grow the company, or keep it a medium-sized family business? “When I asked my team if they wanted to remain a small-but-smart mold shop or grow into a big business with up to 300 employees, everyone agreed to continue doing things in a small way,” Fassnacht says.

Today, the branding “made by Fassnacht” is synonymous with high-quality molds and attracts international customers from the automotive, medical, packaging, electronics and white goods industries. “I never wanted to create a niche for my company. I always thought that it is too risky in times of economic crises, as we saw in 2009,” Fassnacht says. “Today, there is no industry that we are not servicing.”

But like most mold shops these days, Fassnacht faces fierce competition abroad, especially from Asia, he says. So, the company constantly reinvents itself to remain globally competitive. Among Fassnacht’s measures to ensure a solid, future-oriented business is his aforementioned decision to keep the company small and healthy. The company also has heavily invested in automation systems and in a laser cusing machine to additively manufacture mold inserts. He also makes a priority of trusting his employees.

Focus on Core Competencies

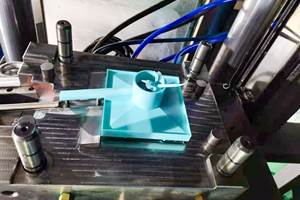

These are the reasons why Fassnacht won the “Toolmaker of the Year” award in November 2017. The Fraunhofer Institute for Production Technology and the WZL tooling laboratory at RWTH Aachen University, Germany, organize the competition. The award’s jury also praised the shop’s decision to outsource less demanding work and its choice to concentrate on its core competencies—the design and manufacturing of multi-component molds, in-mold-labeling and tools with integrated assembly functions.

“We don’t sell machine hours, we sell design and manufacturing know-how and keep our core capabilities like five-axis machining, electrode milling, EDM and design in-house,” Fassnacht says. “Things like plates, rails and other standard parts we buy from other suppliers, which helps our small team to concentrate on the essential tasks.”

“We don’t sell machine hours, we sell design and manufacturing know-how and keep our core capabilities like five-axis machining, electrode milling, EDM and design in-house.”

For the same reason, Fassnacht has continuously invested in automation. The factory’s centerpiece is a five-axis Röders machining center that mills electrodes and other mold components, a CNC measuring machine and two EDM machines from German company Zimmer + Kreim, which has supplied Fassnacht’s handling system as well.

The linear automation system is called Chameleon. It features magazines on a length of 7.5 meters, offering space for 600 electrodes and 21 workpiece pallets. The Chameleon handling robot moves through the flexible manufacturing system on an expandable rail system and can handle pallets from 500 by 500 millimeters and 400 by 600 millimeters.

“We first thought we’d be less flexible with this automation solution, but we soon realized that it pays off to invest in automation and batch-size-one production, even for a small company like ours” Fassnacht says. “Some of our molds require up to 400 different electrodes, which are hard to handle without automation. Moreover, we used to waste a lot of time when we had to interrupt an EDM process for urgent design changes. New setups and machine changeovers caused machine downtime and extra work for the operators. Today, we stop the EDM process, and the handling system temporarily stores the workpiece until the machine is ready to finish the machining process.”

Increase in Productivity

The automated production cell also contributed to an increase in productivity, even though Fassnacht never deviated from his decision to keep his company at a size of 20 employees. He says, “One reason for our increased efficiency is higher throughput. The other is improved quality and higher machining speeds thanks to the new EDM machines, which are about five times faster than our old ones. Spotting times have been reduced, which has a huge impact on our labor costs and our ability to deliver molds to our customers more quickly.” Ten years ago, Fassnacht produced 30–40 molds per year. Now, depending on complexity, the mold shop annually makes as many as 80 injection molds that weigh as much as 5 tons.

While Fassnacht admits that his company has grown from a craftsman’s workshop to a modern mold shop that is inspired by industrial manufacturing principles, it is the people who make the difference. “We need automation to remain competitive, but the key to success is what happens before and after a flexible manufacturing system. The most important factor is the mold design and whether time and money are lost for rework and post-processing. What set us apart are our smart mold solutions and the people behind them.”

While Fassnacht admits that his company has grown from a craftsman’s workshop to a modern mold shop that is inspired by industrial manufacturing principles, it is the people who make the difference.

Investment in Additive Technology

Part of Fassnacht’s smart mold solutions are additively-manufactured mold inserts with conformal cooling. “Molds should earn money in the injection molding process in terms of cost per part, especially when we are talking about large volumes,” Fassnacht says. “Our conformal cooling solutions add value for the injection molder. Very often, however, our customer is not the end-user, but a contractor with a fixed budget. In those cases, it takes some effort and cycle time calculations to convince them to invest in an additively-made insert. Other customers demand designs with conformal cooling channels. Historically, these molds reach achievable and realistic reductions in cycle time in series production of up to 40 percent.”

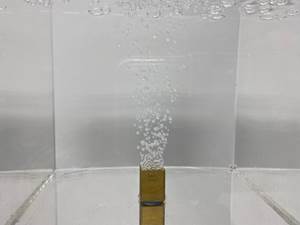

Fassnacht came across the selective laser melting technology as early as 1995. When Concept Laser exhibited its first M3 linear machine as the world’s first industrial 3D metal printing system at Euromold in Frankfurt in 2001, Fassnacht decided to use this technology to create inserts with conformal cooling and hybrid parts, where the complex geometries of the mold insert are “fused” onto a conventionally machined base. When more and more customers started to realize the potential of metal additive manufacturing, conformal cooling and the resulting cycle time reductions, Fassnacht decided to take the technology in-house. He invested in a laser cusing machine from Concept Laser in 2008.

“Meanwhile, we have found ways to manufacture many additively-generated inserts more cheaply than conventionally-machined ones,” Fassnacht says. “Since we cannot use the machine to its full capacity, we also do contract work for other companies, including local mold shops.” According to Fassnacht, competition comes from Asia, not from the mold shop around the corner. He enjoys talking to other shop owners to exchange information and share ideas and news on the latest developments. He says, “Competitions like the one in Aachen bring tool and moldmakers together. This is how I learned about metal additive manufacturing and became one of the first moldmakers to bring such a machine in-house. We all need to cooperate, not compete.”

“We all need to cooperate, not compete.”

Related Content

The Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D-printed parts.

Read MoreVIDEO: How can 3D Printed Tooling Improve Injection Mold Venting?

Proper venting is one of a mold builders toughest challenges as molders struggle to keep vents free flowing in production. Learn how to apply 3D printing to mold venting and the benefits of additive venting inserts.

Read MoreVariable Density-Coated Tool Steel for High-Wear Molds

A mold builder can have an abundance of venting and fully dense solid areas in steel by using variable density sintering to eliminate gas trap defects in high-wear molds.

Read MoreEvaluating Metal Powders for Conformally Cooled Mold Inserts

Mechanical properties and design software techniques reveal the benefits of a modified high thermal conductivity metal powder for 3D printing in moldmaking.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)