3D Printing Workshop at NPE2018

New in 2018, the 3D Printing Workshop at NPE2018–The Plastics Show, is an immersive, half-day workshop focused on emerging technologies in 3D-printing and additive manufacturing impacting plastics and moldmaking.

New in 2018, the 3D Printing Workshop at NPE2018–The Plastics Show, is an immersive, half-day workshop focused on emerging technologies in 3D-printing and additive manufacturing. Presented by Additive Manufacturing Media, Plastics Technology and MoldMaking Technology (I will be there to kick it off), the 3D Printing workshop will build upon a successful model introduced at IMTS 2014 and expanded at IMTS 2016.

Attendees will benefit from a program focused on practical applications of 3D technologies related to plastics processing. This new event will conclude with a 3D Printing Industry Reception sponsored by Additive Manufacturing Media.

The focus of all Additive Manufacturing Events is on industrial applications of additive technologies for making functional components and end-use production parts. It will cover the processes, applications and materials to give you practical knowledge on how to implement AM in your facility.

Agenda

1:15 – 1:45 PM

Multi Jet Fusion vs. Traditional Mass Production Methods

HP has made a lot of noise in media with the Multi Jet Fusion (MJF) technology. Forecast 3D has been providing 3D printing services for over 20 years and currently has over 30 printers— SLA, FDM, PolyJet, MJF and SLM. Decisions to invest in new technologies is not based upon an OEM’s perspective, but real opportunities in the marketplace. Forecast3D invested in 12 MJF systems to specifically target production, not prototyping.

This presentation will not be about what Forecast3D can do, but its experience in the industry and why they have invested heavily into the future of production with MJF. Forecast3D has strategically partnered with customers and industry experts to expedite producing business cases to validate MJF. They will highlight how these customers are executing the implementation of new technologies into their supply chain. While adoption is not simply plug-and-play, there is a path to successful integration and it is not as difficult as some companies may believe.

Attendees will learn how their company can start identifying MJF for production applications, use tools that exist today to identify parts that are more efficiently produced with MJF and show their organization that customers are already using MJF for production today.

- Ken Burns Technical Sales Director Forecast3D

- David Tucker Market Development Manager, 3D Printing, HP Inc.

The Greatest Impact of AM: Conformal-Cooled Inserts

Conformal cooling achieved with metal additive manufacturing and used in injection moldmaking is where traditional manufacturing will be the most impacted by additive manufacturing. To successfully execute the merger of those two disciplines takes planning and a solid process. This presentation will walk through the key elements of this process and address the challenges that arise with each step: Part Design and Simulation, Tool and Water Design, The Supply Chain, The Additive Manufacturing Machines, The AM Build, The Post Processing, Tool Integration, Insert and Tool Quality, Insert and Tool Life, Communication, Project Timing and Project Cost. It is a massive value stream that must be constantly streamlined to work effectively at any real scale. Conformal cooling using direct metal laser melting has its challenges, but the benefits once fully adopted will change tool building, and manufacturing forever.

- Lou Young, President Linear, AMS

New Composite Materials Make 3D-Printed Molds More Efficient and Affordable

Limitations on mold life, cycle time and 3D printing system costs have prevented the use of 3D printed molds to a small percentage of high value, time sensitive projects. The presenter will introduce a new class of composite materials for 3D printing of injection molds that utilize carbon nanotubes and demonstrate how its use can dramatically reduce the cost of producing molds, while improving performance through shorter cycle times and extended mold life. Attendees will be provided with detailed information on how to address the design, printing, post processing and mold operations issues relating to use of 3D printed molds using this new technology printing material. Applications and economics will be reviewed to provide attendees the information needed to identify appropriate mold projects and implement them in a cost effective manner.

Attendees will learn the mechanical and thermal characteristics of carbon nanotube technology (CNT) materials and how they differ from other carbon reinforced materials; the practical requirements for a 3D printed molding material and how CNT-reinforced plastics match up and compare with conventional mold printing technologies. Design for printing issues will be covered, as well as post processing for integration with injection molding systems. Real mold examples will be used illustrate key points. Mold design and printing system requirements and costs will be presented to provide attendees with a costing template to identify what projects make sense using this approach.

- Robert Zollo, President and Founder, Avante Technology, LLC

Specialized Materials for Functional Prototyping and Low Volume Production

The ability to create production-ready functional plastic components is an important growth area for additive manufacturing. However, one of the biggest hurdles in 3D printing is to utilize materials specialized to a specific application. ARBURG’s freeformer open system is capable of running specialized materials to create fully functional components, such as true living hinges made from polypropylene.

Interfacial Consultants, a world-class contract R&D firm in Advanced Materials and Manufacturing Processes that has been actively developing new materials for additive manufacturing, will share how it is uniquely positioned to create customized materials for use in the freeformer at low volumes. For example, environmentally-friendly water-soluble support materials for polyolefins and polyetherimides as well as the first 3D printing purge compound.

Interfacial Consultants will talk about their supports, printing PP and Ultem as well as the purge compound. They will also discuss our interest in small scale production and opportunities in medical applications.

- Thomas Raymond, Manager Additive Manufacturing, ARBURG Inc.

- Dr. Philip Brunner, Director of Strategic Accounts, Interfacial Consultants

Influence of 3D Printing on Safety-Critical Performance Properties

UL will share its latest research findings on the impact of 3D printing on safety-critical printed part properties, such as flammability, ignition, and electrical properties that were investigated for different 3D printing parameters. Results were also compared to conventional, injection-molded samples. Based on these new findings, and combined with known mechanical behavior, UL will highlight an approach for acceptance of 3D printed materials and components in end-use products.

- Thomas Fabian, PhD R&D Manager, Material Science, UL LLC

- Kenneth R. Vessey Jr.Staff Engineer, Performance Materials Division, UL LLC

3D Printing Versus Injection Molding–New Technology Changes The Balance

EDM did not replace the CNC machine. It is another way of removing material from a solid block. Now just about every shop has both types of technology to make molds, inserts or parts. The same can be said for 3D printing or additive manufacturing. It is not a fit for all parts, but it is a fit for some parts. That list is growing every day. We need to look at the bigger picture.

Carbon, a toolless injection molding machine, is creating a new category of manufacturing and accelerating into production. It is the first company to create non-porous parts from materials, comparable to existing thermoplastics in material properties and stability. At the intersection of hardware, software and molecular science, Carbon enables you to prototype and manufacture parts in same material and technology.

- Scott Kraemer, Production Development Engineer, Carbon

The Promise of 3D Printing for Shoe Manufacturing

3D printing is one of the key trends in the industrial world. It is said to change the way we make things. In particular, the footwear industry is one of the leading industries in terms of adopting this innovative technology.

Thus EOS, as a world leader in industrial 3D printing and Under Armour, a world leading manufacturer of sports performance apparel, footwear and accessories have teamed up to provide superior solutions to the market. This presentation will provide an insight into the partnership and discuss how 3d printing impacts the footwear industry. In addition, an overview of further applications where 3D printing is applied successfully will be delivered.

- Lester Hitch, Life Cycle Solutions Specialist, EOS North America

5:30 - 7:00 PM

Networking Reception at 3NINE Orlando

The 3D Printing Industry Reception features food, drinks and a number of opportunities to network with industry professionals that can help your business.

Register today!

Related Content

Plastic Prototypes Using Silicone Rubber Molds

How-to, step-by-step instructions that take you from making the master pattern to making the mold and casting the plastic parts.

Read MoreVariable Density-Coated Tool Steel for High-Wear Molds

A mold builder can have an abundance of venting and fully dense solid areas in steel by using variable density sintering to eliminate gas trap defects in high-wear molds.

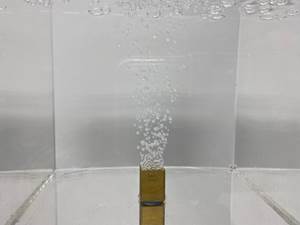

Read MoreVIDEO: How can 3D Printed Tooling Improve Injection Mold Venting?

Proper venting is one of a mold builders toughest challenges as molders struggle to keep vents free flowing in production. Learn how to apply 3D printing to mold venting and the benefits of additive venting inserts.

Read MoreTechnology Roundup: Additive Manufacturing, Mold Materials

Upgrade your manufacturing process or tool steel choices with new/improved additive manufacturing and mold material innovations from AddUp Inc., Mantle, Next Chapter Manufacturing, Edro and more.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

_300x250 4.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)