MMT Blog

Four Industry 4.0 Tech Adoption Insights from Indiana Plastics Manufacturers

As more plastics manufacturers step into the Fourth Industrial Revolution, insights have emerged about how best to approach the digital transformation journey.

Read MoreUnveiling Excellence: The 2024 Leadtime Leader Award - Who Will Claim the Crown?

MoldMaking Technology’s Leadtime Leader Awards competition comes to a close as the community discovers the 2024 winner at NPE on May 7 at 4 p.m. in Booth W2143. Make your plans to be there!

Read MoreHow to Machine Aluminum Molds to Enhance Efficiency and Quality

Ways to optimize the machining process to fully leverage the benefits of an aluminum mold.

Read More3 Es of Small, Family-Owned Mold Shop

Isaac Trevino, Business Development Manager, with Best Tool & Engineering is a mechanical engineer and entrepreneur at heart. In this interview, he talks about working in the business of moldmaking, evaluating ERP solutions, making partnerships to train the next generation and managing expectations.

WatchRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

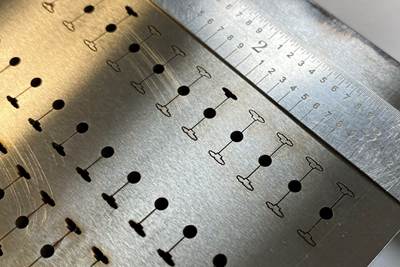

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreWho is Our 2024 Leadtime Leader Winner?

Our Leadtime Leader Competition has been an ongoing award since 2003. It is a prestigious award given only to North American mold builders who excel in moldmaking. Find out when and where you need to be for the reveal. Sponsored by Progressive Components.

WatchERP Empowers Mold Builder to Increase Speed, Efficiency, Accuracy

Highly integrated but easy-to-use ERP system helps Delta Mold Inc. increase unattended hours, uptime, productive labor hours and improve mold delivery times.

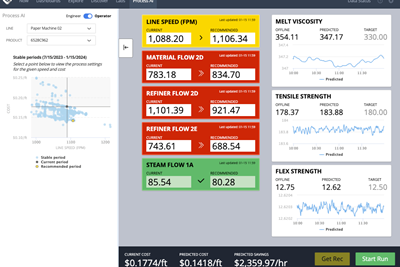

Read MoreUse AI, Machine Learning to Take Variability Out of Manufacturing

Variability has always created insurmountable challenges for manufacturers. However, in the last decade, impact has been more painful due to a lack of experienced workforce. By leveraging technological advancements, particularly in AI, manufacturers can gain a transformative competitive advantage in both cost reduction and workforce development.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreInjection Molds and Integrated Solutions Through Ambition and Innovation

Jordan Robertson, VP, Business Development and Marketing for StackTeck discusses various mold technologies to improve efficiencies in automation, cooling, lightweighting and sustainability.

WatchHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More