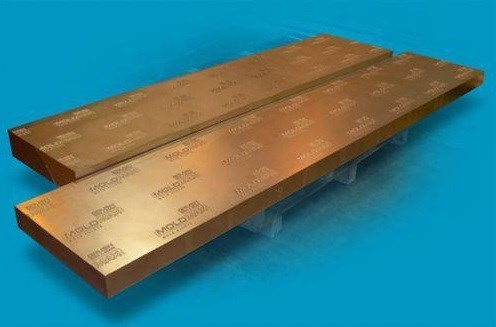

Copper Alloys for Injection, Thermoform and Blow Molds

Appears in Print as: 'Webinar: Copper Alloys for Injection, Thermoform and Blow Molds'

June 23 at 2pm EST, MoldMaking Technology is hosting a webinar that will review the strengths and weaknesses of the copper alloys used in plastic molding today. Register here.

#aluminum

Materion Performance Alloys has worked with MMT over the years providing technical content on a variety of mold material issues, including common mistakes with copper alloy usage and copper alloy classes. That education continues tomorrow, June 23 at 2pm EST when MoldMaking Technology hosts a webinar by Materion that will review the strengths and weaknesses of the copper alloys used in plastic molding today.

Topics will include: how copper alloys differ from steel in plastic molding, how copper alloys can improve the plastic molding process and characteristics of copper alloys versus steel.

Watch the recorded webinar here.

RELATED CONTENT

-

Reaching the Next Level of Efficient Machining

Clamping devices can help to achieve fast and efficient mold plate and cavity/core insert changes during machining.

-

A Review of Copper Alloys for Plastic Injection Molding

Copper alloys are attractive to the mold industry because of their high thermal conductivity, ease of machining by a variety of processes, and corrosion resistance to water, cooling fluids and the plastics being injected.

-

The Realities of Aluminum Tooling

Using aluminum tooling instead of traditional tools steels reduces cycle time and costs, but requires up-front, open communications between moldmaker, molder, material supplier and hot runner manifold supplier.