Uniloy North America: Total Systems Outlook

Uniloy North America has specialized in blow mold machine and mold manufacturing for more than five decades.

Share

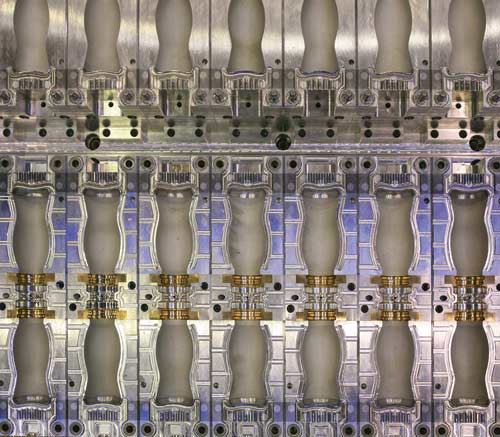

Uniloy North America (headquartered in Tecumseh, MI) has specialized in blow mold machine and mold manufacturing for more than five decades. With more than 150 employees in the Tecumseh location and 50 employees in its Batavia, OH location (where machinery manufacture takes place), the company offers complete turnkey solutions for blow molding operations—which include machinery, molds, tooling, training and service. The company also can supply auxiliary equipment such as resin handling, leak detection, trimming, conveying, labeling and filling. Industries served include packaging for food, pharmaceuticals, petrochemicals, household and personal care products, industrial and automotive parts.

According to Uniloy’s New Business Development Manager Dan Meehling, the company goes beyond the design and manufacture of blow molds, it focuses on the entire manufacturing process for blow molded parts and containers. “This entails container design, R&D lab/prototype manufacturing, engineering, market and systems testing and field service technicians that follow the molds into the customer’s plants and install and train their employees,” Meehling elaborates. “We don’t just cut cavities—we understand our customers, their markets, the dynamic demands on their containers—basically, every element of processing productivity. Beyond new molds, we also offer a 10-step repair and refurbishment program to get new life from existing molds. And, for many applications we can offer rental molds to keep our customers productive. It is a total systems outlook.”

Technical Know-How

A critical aspect of Uniloy’s blow mold operations is its dedicated test lab and blow molding machinery—located next to where the molds are manufactured. Meehling notes that the company’s experienced leading process technicians and the latest in blow molding equipment allows the company to optimize performance of its molds and trim tooling while assimilating the actual environment in which its customers will be running production. “We also are able to assess the container design and material used to determine the appropriate blow molding process—whether it be reciprocating screw or continuous extrusion and appropriate trimming options to create the maximum container output for the customer,” he says.

Plus, the company’s more than 50 years of experience providing packaging for such markets as the dairy, juice, water, medical and pharmaceutical—among others—have provided Uniloy employees with an “intimate” understanding of the challenges facing its customers and allows them actively participate in the development of packaging solutions no matter what the need, Meehling adds. “We are so involved in the dairy market, for instance, that I like to joke that our people know how to make cottage cheese, let alone container systems for fresh and long shelf life milk. When our customers come to us for a new package, we enjoy a head start on devising a solution that our competitors do not have, especially those that don’t also manufacture blow molding machines.”

Instead of waiting for opportunities to come to Uniloy, Uniloy anticipates the market with packaging concepts that will meet the challenges and requirements of its customers. Lightweighting, barrier dynamics, new materials, serving size, etc. are some of the aspects that Uniloy is constantly monitoring and addressing to lead the market and create “pull through” opportunities.

And, Uniloy enjoys spreading its capabilities and product innovations through word-of-mouth of its most satisfied customers. “Our domestic success has been a huge advantage for us in terms of taking our business to all areas of the globe,” Meehling states. “Whether that’s an organic dairy who wants to extend geographic reach through Extended Shelf Life (ESL) technologies, or a custom molder who wants to speed changeover to improve their product mix, or whatever, when foreign businesses look to the United States for recommendations for their particular application, more often than not, Uniloy is the supplier of choice.”

Maintaining Sustainability

According to Meehling, companies that don’t pay attention to sustainability as a concept that will impact their business will be in trouble. “We see sustainability as an extremely important issue and are paying close attention to it as we shape our strategies going forward,” he states. “Typically, our applications are packaging or packaging related—wherein, the driver for that market has become sustainability. Environmental, social and most importantly, economic (cost) pressure are making it mandatory for businesses—especially packaging concerns—to pay attention to this fast emerging concept.

“At the moment, I believe that no consensus on the definition of sustainability exists,” Meehling continues. “The concept is causing confusion in the market, some companies are suffering from ‘sustainability fatigue’ and that there are

suspect and arbitrary claims by companies of being sustainability compliant. Nonetheless, those that truly understand the underpinnings of the concept, given the economic upside, will broaden their opportunities this year and in the years to come. And, we are finding that the solutions are sometimes counter-intuitive to conventional thinking. That is where the real opportunity exists!”

Meehling forecasts continued success for Uniloy. “By continually building on our strengths, we will broaden our reach into new and emerging markets, stretch the technical and application capabilities of its machinery platforms and enhance our aftermarket service and product portfolio.”

Read Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)