Understanding True Asset Utilization and Its Implications On Profitability and Leadtime

Asset management, data collection, and maintenance and tooling management systems are essential to improving shop efficiency.

According to a 2006 report by China’s Die and Mold Industry Association, the country is still importing more molds than they are exporting. However, between 2004 and 2005, exports had grown 50 percent, whereas imports had grown just 14 percent.

In response to this global competition, some domestic moldmakers are zeroing in on labor costs. They assume labor is the main competitive advantage of the emerging economies, and that capital costs are reasonably level globally. They make further

assumptions about the efficiency of their operations based on perceptions, and rush to automate a potentially flawed process.

According to a 2005 Plante & Moran study of the plastics industry, successful moldmaking businesses were utilizing their equipment more than four times more than companies that were struggling, based on a potential 24/7 operation (see Figure 1a). Successful companies also had an average leadtime of 36 days per mold versus 77 days for the less successful group (see Figure 1b).

Typically, companies are not aware of their true asset utilization and its implications for profitability and leadtime. When challenged to improve performance, they usually focus on equipment and labor issues, and rarely consider other inefficiencies. Increasing utilization delivers more machining capacity to improve leadtimes.

While there is no silver bullet for improving utilization, there is low hanging fruit, which can be found if robust data collection is used to uncover the lost capacity in operations, and to keep processes running smoothly.

Why Is Machine Tool Utilization So Low?

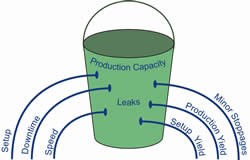

Moldmakers use EDMs and machining centers to manufacture relatively large and complex parts; however, a significant portion of the potential machining capacity of the operation can be wasted though numerous small leaks in efficiency (see Figure 2).

Machine tool setup is a lengthy, complex and error-prone process. To manufacture a mold, a part program, the material and the necessary tooling must be assembled at the machine tool. Mold part programs are typically very large, yet some manufacturers still download them using slow serial communications. Material blanks are also very large, and they must be referenced to the machine tool zero using work offsets and coordinate rotation settings. Tool lengths and diameters must be measured and entered in tool geometry tables in the CNC, and test cuts must be performed to adjust tool wear offsets.

Machine downtime can also leak capacity. Setup errors can lead to machine crashes. Electrical storms can lead to a loss of critical files stored in the CNC, and if backups are not readily available, it can take days or weeks to get the machine back into production. Though modern production equipment and CNC controls are very reliable, unplanned downtime can occur if routine maintenance is not performed in a timely manner.

Machine processing speed is typically assumed to be fixed by the capabilities of the machine, but high-speed machining techniques can change the equation, especially for the complex contours typical in the mold industry. Part programmers often set very conservative feedrates to allow for process variation in material, tool condition, width and depth-of-cuts. Operators can override programmed processing speeds for a variety of legitimate reasons, including a lack of experience.

Minor stoppages for tool maintenance vary significantly from operator to operator and from tool vendor to tool vendor, and few companies have policies or a system to manage tool life. Some companies prefer to use low-cost tooling and machine at relatively low speeds, whereas others invest in high-performance tooling to process at higher speeds, believing that the productivity of the applied assets and labor are more important.

A marginal quality process capability also leaks operation efficiency. Low-grade equipment or poorly adjusted equipment can make the difference that determines if an operation relies on hand finishing and rework, or has the confidence to cut-to-zero.

Machine tools and their related processes can be very inefficient, but it is important not to make assumptions and rush to implement expensive solutions. Very small training or process issues can prevent large capital investments from delivering the expected returns.

The organization must take the time to collect data about what is really happening on the shop floor, and build organizational credibility by implementing the highest-impact, lowest cost solutions first. This approach to continuous improvement is the only way to get sustainable support from management and workers, as the initial results build the emotional and financial credibility for future projects.

The Essential Role of Data

Without data, companies tend to invest in large silver bullet investments based on a few individual perceptions of what needs to be fixed. Even if the investment is sound, it takes a very long time to achieve a positive ROI. The investment can be derailed by other small problems, and since there are limited opportunities to make large investments, only a few individuals experience its effects.

In practice, there are numerous opportunities for low-cost investments that can have a significant impact on operational efficiency. Smaller projects can produce shorter term ROIs, and engage a larger percent of the production team in continuous improvement projects. Most of this low-hanging fruit addresses process standardization and training issues, adopting low-risk best practices already proven to work within the organization.

Manual data collection rarely produces acceptable results. Bias from both shop floor workers and management teams tends to mask reality. It is resource intensive, so only very basic data can be collected. Each department or function collects their own data and therefore inter-function process improvement discussions wastes time trying to determine or defend whose data is correct.

Today’s machine tools, robots and quality measurement systems are Ethernet-capable, and most allow a wide range of data to be collected automatically. The accurate recording of what parts are running on a machine, the cycle time, part counts, error messages and other essential events builds a complete accurate picture of what is really happening on the shop floor, freeing up resources to perform analysis and process improvements.

Looking at the same data from multiple points of view provides insight into best practices and potential problems. Analysis by operator, shift, machine and various time periods all uncover specific opportunities. Analysis by the percentage of lost production, the number of occurrences, mean-time between failure and mean-time to repair or recover, can each expose a different element of the same best practice or problem (see Figure 3).

Automated data collection and analysis tools capture the complete picture of machine efficiency, allowing manufacturers to identify the best practices that are already proven to be effective within the organization. Identifying quick-return, low-risk investments, builds credibility and eliminates the multitude of small problems that may prevent a larger automation investment from producing the anticipated returns.

Asset Maintenance and Tool Life Management

Maintenance and tooling budgets receive the most pressure in all machining operations, because they are every day expenses. Even though maintenance practices and tooling technologies can significantly impact the performance of the equipment, the hourly cost of the capital invested and its related overhead are sometimes forgotten. Surprisingly, few companies have written policies or systems to manage the costs or effectiveness of maintenance or tooling.

Some companies have invested in Computer Maintenance Management Systems (CMMS) or Asset Management systems, but they tend to be used only to schedule resources and record what work was performed. Preventative maintenance is scheduled in calendar time based on manufacturer’s specifications or the maintenance team’s experience. This often leads to higher than necessary maintenance costs.

Some components such as ballscrews and slideways are only wearing when the axes are moving. Components such as lubrication pumps may only be operating periodically. Components such as circulating fans are running all the time that power is applied, whereas batteries are only being utilized when the power is removed. The high-speed spindles that are used extensively in moldmaking may have wear profiles that depend on the speed and power that is being applied.

Asset maintenance life management systems (see Figure 4) can collect data from assets to determine if power is applied, axes are moving and the spindle is turning, and the data can be used to accurately track how components are being consumed. When an asset life remaining is below a threshold value, preventative maintenance can be scheduled in advance. Any other low-cost components that are close to the end of their maintenance life can be included to minimize the number of interventions. Components that have a limited number of maintenance cycles before replacements are required can also be managed.

By managing interventions based on usage rather than calendar time will reduce direct maintenance costs, and prevent the unnecessary loss of production capacity. Maintenance teams can use the system to perform smaller interventions and prevent the backlog that typically occurs at plant shutdowns.

Some companies have invested in tool inventory management systems, either using people in a controlled toolroom or with a vending-machine tool dispenser. This answers the question of how much tooling is being used, but it does not tackle overall effectiveness.

Some operators change tooling based on the sound of the cutting process, whereas others rely more on visual inspection of the parts produced. Some operators are quick to replace tooling on the first negative indicator, whereas others may take a more holistic approach. This variation can increase tooling costs significantly.

Tool management systems can be integrated in the CNC or applied externally to monitor tool life and apply policies for tool maintenance (see Figure 5). For machining centers, cutting time, cutting cycles and cutting power data can be collected for each tool in each machine. Similar characteristics can be collected for EDM machine electrodes. Appropriate thresholds can be established for each tool, considering the tool technology, material and the cutting application.

Any tool that prematurely fails to reach the policy threshold is investigated and the reason is collected for later analysis. Variance in tooling vendor performance can also be analyzed, and establishing the tool maintenance policy eliminates the operator-to-operator variation.

Tool management systems can also extend machining cycles by providing multiple tools for each operation. When a tool reaches one of the policy thresholds, an identical tool can automatically be selected. For an EDM, this may require an investment in a robotic toolchanger. This element of tool management minimizes the amount of operator supervision required, and is part of the solution to running machines unmanned on additional shifts, and achieving 24/7 operation.

Summary

In the U.S., asset utilization varies between successful and struggling moldmaking companies. Managing assets has many dimensions, and efficiency leaks can be found in setup, downtime, speed, minor stoppages and process capability. Data collection plays a critical role in understanding specific problems, formulating part of the solution, and monitoring and sustaining process improvements. Initially, the data will point to simple improvements that require a minimum of capital outlay, building credibility for future investments. Maintenance and tooling management systems, in particular, can play a role in managing two of the critical elements of machining. Achieving efficient, 24/7 operation will also provide the machining capacity to shorten leadtimes and make domestic moldmakers globally competitive, despite the challenges in labor costs.

Related Content

What You Should Consider When Purchasing Modified P20 Steel

When buying P20 steels that have been modified, moldmakers must be aware of the variations and key issues that affect delivery, cost and lead times.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreRead Next

How to Achieve Tool Shop Optimization

A five-step methodology to face your delivery, quality and cost challenges head on.

Read MoreHow to Solve Common Inventory Management Problems Related to Tooling

A practical look at what to consider when purchasing client/server inventory management software and how to implement such a program, as well as why and how it can benefit mold manufacturing operations.

Read More

_300x250 4.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)