Tips for Successful Hard Milling of Complex Molds

And when mold and die applications demand hard milling of materials up to 66 HRC, using the right end mills, cutting parameters and machining methods is critical for success.

Today’s moldmakers are seeking reduced leadtimes while producing highly accurate molds. And when mold and die applications demand hard milling of materials up to 66 HRC, using the right end mills, cutting parameters and machining methods is critical for success.

Hard milling is challenging due to several factors, including the requirement of machining hardened steels with defined cutting edges. Milling these materials requires high-speed machining centers that are set up for hard milling, along with CAD/CAM that has been programmed accordingly.

Using the latest solid carbide end mills along with proper toolholding, workholding, feeds, speeds and cooling, mold manufacturers can reliably and economically produce complex molds. Complicated contours can be accurately machined, and time-consuming grinding or polishing rework may be omitted entirely, or at least partially.

Choose end mills that meet the following requirements: solid carbide substrate with a high hot hardness and toughness; coating and cutting geometry matched to the material hardness; and, tool concentricity not exceeding 5 microns (meeting this requirement will extend tool life and promote excellent surface finish quality).

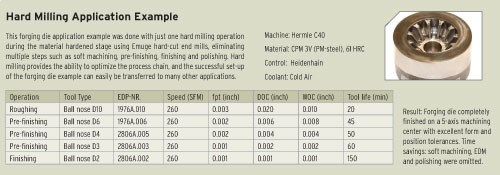

Determining the optimal cutting parameters and methods will yield the best results for hard milling of molds. Select a speed and federate that is recommended for the type of workpiece and material hardness as well as the engagement conditions of the tool. Consult your end mills partner for technical data recommendations for specific applications. When hard milling, dry machining is preferable in order to avoid thermal cracks in the cutting tool. For example, when using multi-flute end mills, cold air provides an effective cooling of the tool’s cutting edges, resulting in efficient chip material removal.

Cooled air reduces temperatures in the cutting area, which in turn permits higher cutting speeds and up to 30 percent longer tool life. This type of cooling enables modern TiALN coatings to achieve their full potential, avoiding damage to the cutting edge from thermal shock. In addition, the cold-air nozzle helps to remove the tiny chips produced in copy milling, including from deep recesses or cavities in the mold.

Proper clamping of the tool and workpiece are also important for successful hard milling—including high rigidity and good vibration damping of the machine tool and the workholding devices; and, high concentricity of the toolholder for high surface finish quality and consistent tool life.

Hard milling with solid carbide end mills is an established and reliable way to manufacture molds with hardness of up to 66 HRC. Secondary and grinding operations can be omitted for increased productivity and enormous cost savings.

Related Content

-

Surface Finish: Understanding Mold Surface Lingo

The correlation between the units of measure used to define mold surfaces is a commonly raised question. This article will lay these units of measure side by side in a conversion format so that companies can confidently understand with what they are dealing.

-

Exploring ISO 9000 - Part 16 Control of Quality Records

A Series of International Standards for Quality Management and Quality Assurance. We begin 2022 with a review of Clause 4.16 Control of Quality Records.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

.jpg;maxWidth=970;quality=90)