The RP Education Problem

Lack of awareness and education is impeding the growth and expansion of the rapid prototyping industry.

There is a major problem that impedes the growth and expansion of the rapid prototyping (RP) industry. No, I am not talking about high costs. The real problem is the persistence of a lack of awareness and education. It is appalling that this topic is relevant fifteen years after the inception of the industry. Without significant improvement in RP awareness and education, you will probably be reading these very same words five years from now.

For those that doubt the validity of this claim, let me offer some evidence. But first, let's agree that the goal is knowledge, and this comes from a combination of awareness and education. To merely list a few technologies or describe the general process is not enough. The goal is knowledge and understanding that is sufficient for the consideration, evaluation and selection of an appropriate prototyping methodology.

Recognizing the Information Gap

For four years, I led a panel discussion on the future of RP at the Society of Manufacturing Engineers' (SME) Rapid Prototyping and Manufacuturing Conference (RP & MC). In each of those sessions, the bulk of the discussion has centered on what it will take for this industry to flourish. Every year, the answer has remained the same: awareness and education. Twelve industry experts voiced this opinion on four separate occasions.

To further illustrate the problem, consider large companies with substantial RP operations. A challenge that most face is raising awareness of the technology and fostering new users. Some estimate that only 15 to 20 percent of their organization takes advantage of their in-house RP operations. More frightening is that the majority of the employees are unaware that the technology is available to them.

Still don't believe that the RP industry has an education problem? As a test of the understanding of the technology and industry, answer these questions.

Do you or does anyone you know...

- Use LOM as an example of RP?

- Use SLA to describe technologies other than stereolithography?

- Believe that SLA produces brittle parts?

- Believe that RP is too expensive?

- Believe that FDM is very slow and inaccurate?

- Read articles that list Cubital as an RP vendor?

If you answered "Yes" to any of these questions, you can appreciate the dire lack of awareness and education. For those that don't understand that "Yes" is an indicator that there is an information problem, it is definitely time to get up to speed.

Impact of the Information Gap

As an informed person, why should you care that the rest of the world is woefully uninformed? The reason is that it affects you, your department and your company. The ignorance of industry is limiting your access to advanced technology and materials. The unknowledgeable may be keeping your cost for equipment, materials and services artificially high. The uninformed may be endangering the justification of your RP operation.

As the knowledge gap is bridged, the RP industry will grow. This growth translates to sales and profits, and offers evidence of future opportunities. As a result, vendors have the financial resources and motivation to invest in R&D. This, in turn, delivers new advances, new technologies and new materials on which you can capitalize. These advances further increase industry growth, which fuels an upward spiral in functionality and capability.

As the number of systems sold increases, costs may decrease. It is expensive to develop new technology and materials. When this expense is amortized over hundreds of systems, the impact on price is appreciable. When the costs are spread over thousands of users, vendors can decrease prices without negatively affecting their profitability.

Internally, a lack of awareness and understanding diminishes the number of opportunities to apply RP. If the majority of your design and manufacturing team does not use the technology, the company loses the benefits of RP and that diminishes the value of the solution. This can put budget requests for upgrades, materials and additional systems in jeopardy. In some cases, this may jeopardize the continuation of the in-house RP operation.

I could go on, but I think this is enough reason to motivate the informed to care about the uninformed. Hopefully, there also is enough motivation to do something about it.

Old Information and Established Beliefs

The information gap is actually a Catch 22. On one hand, few have been given cause to become informed on the latest in RP. On the other hand, those who want to be knowledgeable find that there is a limited supply of good, reliable and factual information available to them.

With so little time and so much to do, few will make the effort to reevaluate old decisions or to reinvestigate established beliefs. If we reevaluated every decision and every belief, there would be no time to get anything done; yet, we must recognize the hazards of operating on old information. Ignorance is not bliss, it is dangerous.

What it takes for someone to reevaluate old decisions or to reinvestigate a topic is a reason. This motivation can come in many forms: keeping up with peers or competitors, job security, project demands or corporate initiatives. In each one of these examples, there is the motivation to invest our most valued resource—time—to make new, informed decisions. With the limited size of the RP industry, there is not enough external motivation to dig in and learn the technology. And with the limited informational resources on the topic, there is little that sparks an internal motivation to become knowledgeable.

RP is still perceived as a time machine. In a business cycle where speed has been overshadowed by cost cutting and cost control, why bother investigating the technology? When published articles cite the same old benefits and reuse the same tired case studies and feature the same companies again and again, what motivation is there to dig in and learn the latest on RP?

As one of the informed, you have already discovered the lack of information on RP. Somehow you managed to find the information that you needed. I bet that for many of you, it came the hard way: first-hand experience. You had the motivation, you invested the time and effort to find the facts that you needed and you spent the time to learn the topic. How many others would go through this effort? You have experienced the scarcity of information and you recognize the barrier that it imposes.

The problem is huge and multifaceted. Everyone must take some responsibility and everyone must do something about it. Users, non-users, companies, vendors, the media and trade associations can take action to rectify the situation. The RP industry must address both sides of the Catch 22 simultaneously. The industry must build the information resource stockpile while building the motivation to seek it out and learn from it.

Action Required

To break the cycle of ignorance, we must work on both sides of the issue. We must motivate the uninformed to take another look at RP and to become knowledgeable on the topic. At the same time, we must generate more information for these investigators to absorb.

As individuals we can make a difference. Start by mentoring a student or peer. Introduce them to the topic and provide the spark that ignites the desire to learn. Continue your efforts by contributing your knowledge and experience. You could speak at a conference or seminar or offer a first-hand account to an article or case study. Make your information available to the public; don't hoard it as a valuable asset that gives you a competitive advantage. If you don't have the time or inclination to contribute in these ways, something as simple as attending and participating in industry events can help. Your attendance builds further justification for the association to continue with future events. Just by attending and sharing your experience with the RP novices, you help to build the motivation to learn and begin to fill the information gap.

As individuals, we also can affect change by demanding information. Let's demand more information and a higher quality of information. Let's demand facts and not accept bold claims. Let's expect more from those that possess the wisdom of RP.

Demand, share, inspire and contribute. That will build the bridge over the information gap. Once bridged, the industry can accelerate the delivery of better tools, advanced applications and lower costs.

Related Content

3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.

Read MoreProducts and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

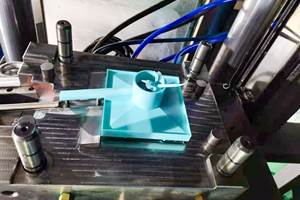

Read MoreVIDEO: How can 3D Printed Tooling Improve Injection Mold Venting?

Proper venting is one of a mold builders toughest challenges as molders struggle to keep vents free flowing in production. Learn how to apply 3D printing to mold venting and the benefits of additive venting inserts.

Read MoreEvaluating Metal Powders for Conformally Cooled Mold Inserts

Mechanical properties and design software techniques reveal the benefits of a modified high thermal conductivity metal powder for 3D printing in moldmaking.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)