The Need for Speed

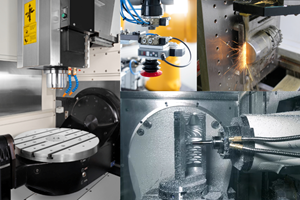

The trend for higher speeds in machining technology has moldmakers scrambling for the cash to purchase this equipment and the subsequent training to bring them "up to speed".

Industry demand for shorter delivery times has resulted in the advent of high-tech machining equipment and tools that are designed to make the overall moldmaking process more efficient and allow the moldmaker to design more complex molds without sacrificing speed. Most moldmakers believe that they are staying on top of the technology, but some still see a demand for more education and equipment to master these more complicated processes.

Machining Challenges for Moldmakers

According to Randy Pocker, president of Exact Mold & Die (Cleveland, OH) - a builder of molds of up to 10 tons, single- and multi-cavity projects, replacement cavities and components - keeping up with the new technology has been challenging. "Some of the machine tools won't allow you to use the latest cutting technologies since they were never designed to use those technologies [i.e., high-speed machining]," he comments. "Some machines are not run to the full potential since we don't have the time to spare to send employees to training in the advanced courses."

For Auburn, ME-based Creative Machine Co. - a mold builder for a number of industries - the biggest issue with machining technology is machine breakdown. "Ninety-nine percent of what we run is aluminum, so when you run aluminum, it doesn't matter if you are running a one-inch or a .0010-inch cutter, it's running at full speed top rpm - just pushing the machine as fast as it will go - and it's hard on the machine," explains James Cornwall, an engineer responsible for all of the company's 3-D modeling and CNC programming. "A lot of moldmakers run steel, which is run a lot slower, so it isn't as hard on the equipment. So we've been looking at different models."

Cornwall adds that cutters also have been an issue. "Since we make molds for foam, rubber and flexible materials, the biggest problem we've found is that we try to do everything with two pieces: a top and a bottom," he explains. "There's no slides, no moving pieces, so you are trying to put all of this geometry into two pieces and it becomes very complex. We actually cut undercuts, which in hard plastics is a no-no because then you can't get the part out. But when you have a soft, flexible part you can actually have an undercut and pull the part out."

Exact Mold & Die's Pocker would like to see affordable machining technology that is more knowledge-based and user-friendly while also being less dependent on the skills of the operator and capable of running unattended. His wish list also includes machine tools that can be upgraded in the future.

Daniel Rubner, manufacturing manager for Eagle Tool Company (Dyresville, IA) - a manufacturer of plastic and die cast injection molds for a number of industries - reports that the company is currently updating its drilling equipment and is looking into milling at higher speeds. "We'd like to be able to mill hard steel - right now we are only milling electrodes and then EDM'ing the cavities out," he states. "In the next year we will be purchasing another CNC machine or milling machine."

The same goes for Creative Machine. "I've met with half a dozen manufacturers and suppliers, and we're planning on hiring another engineer to do more programming when we purchase more CNC machines throughout the next year," Cornwall comments.

Generally, the state of the economy has thus far prevented Exact Mold & Die and Creative Machine from implementing this technology in-house. Cornwall adds, "Money isn't the only factor as to why we haven't yet purchased these machines - you also have to justify the purchase as far as workload goes. You have to more than need them for awhile. We're a small company, so if we're buried for awhile and that workload maintains, the cost can be justified."

A Machinist's Wish List

It seems as if moldmakers can readily identify their machining needs. But what is it that they wish for? For Eagle Tool's Rubner, he'd like more innovations in software specifically. "I wish there were a way to be told that everything was cut," he says. "We do a lot of 3-D contouring and if you go into a part that has sharp corners and don't get all of the material out of there, I wish that could be highlighted. Right now, it's up to the operator to pick out those little corners and make sure that he gets in there. Our parts are pretty complicated - you have to look very carefully to make sure that everything is gone."

Cornwall of Creative Machine wants a new cutter. "I would love for someone to make a spherical cutter - a quarter-inch sphere with an eighth-inch shank on it," he states. "I know of no one who makes them." Something else that Cornwall feels is more of a possibility is remote monitoring of the shop floor. "We would like to be able to - through our website - go online, log in privately and actually have video cameras on the machines, so we can check things out remotely," he adds. "We run the machines all night and that would help avoid downtime if there was a problem. I could just call one of our employees that lives down the street and have him start the machine back up."

Advice to Put Into Practice

No matter your needs or wants, Pocker of Exact Mold & Die advises moldmakers to constantly seek out training to stay on top of technology. "Try and stay as current as possible in the machine tool area by constantly grooming and cultivating customers that allow you to make enough profits to keep this investment up and see if new technologies are adaptable to moldmaking," he states.

Don't go by price alone, cautions Cornwall. "Be careful what you buy - don't go to the lowest bidder!" he advises. "Also look at the quality of the equipment."

According to Bob Hazelton, supervisor of electrode manufacturing, Medsource Technology (Pittsfield, MA) - which builds molds for medical devices - the key to utilizing high-speed machining is to let the technology do the work. "Get your unattended hours up on the machines," Hazelton urges. "Don't let someone mill something for an hour when you can throw it in a CNC, shut off the lights and go home and it can get done without any human error. Use your head. This is the way the industry is heading - everything is going to high speed and software."

Manufacturers' Machinations

Currently the machining industry's focus is on the need for speed. Machines are being designed with higher speed rates and higher speed spindles so that moldmakers can be quicker and more efficient. Cutting tool and software improvements also will help moldmakers who cannot yet afford this technology to enhance their current equipment.

What major advancements do you foresee in machining technology (high-speed machining, five-axis machining, milling, grinding, gun drilling, drilling, boring, cutting and engraving) this year?

Richard Layo, president, Dynamic International, Inc. (Pewaukee, WI) - suppliers of a complete line of machining equipment: With regards to high-speed machining, there is definitely a trend toward higher feedrates and higher speed spindles - 30 to 40 percent faster than even five years ago.

Although the economy right now is soft, I think that things will pick up in 2001 and it will be a very good year. Everyone is waiting on the interest rates to see what will happen. If moldmakers can't afford the new machines, and own machines with computers that are less than five years old, a lot of times software can be added to upgrade these machines and enhance their performance. It won't bring it up to current technology, but it will improve the machining capabilities dramatically over what is being done now.

Jim Sundberg, VP sales, TechniDrill Systems, Inc. (Kent, OH) - manufacturers of a complete line of deep hole drilling machines: We see everything moving toward a floor-type, four-axis, deep-hole drilling machine accepting molds in excess of 200,000 pounds. This machine is virtually unlimited as to the size of the mold that can go on it and will permit the use of either gun drills or BTA (single-tube system) tooling, milling cutters, counterbore tools and caps.

Hans Beek, manager of applications engineering, Toshiba Machine Co., America (Elk Grove Village, IL) - manufacturers of a complete line of machining centers and machine tools: It's all going to be in the controls and in the machine tools. Our goals are to get longer life from the tooling so that we don't have to exchange it that often - and higher speeds of course.

Roy Garrison, advanced systems engineer, Toyoda Machinery USA (Arlington Heights, IL) - supplier of CNC horizontal machining centers: Larger machines will be introduced this year, and more linear motor machines. Larger machines need to have better acceleration/deceleration and higher speeds. We're machining a lot of the same things that EDM machines are doing right now, so anything that's not tremendously deep or has sharp corner radiuses, we can cut on our machines and actually reduce the time.

David Mann, assistant sales manager, Yasda Precision America Corp. (Elk Grove Village, IL) - manufacturer of high precision machine tools: We are machining very efficiently and accurately on very hard materials - thanks to improvements in machine structure, spindle stiffness, cutting tools and toolpath software. It's now possible to machine Rockwell 60 material and harder.

How will these advancements affect the moldmaker, mold designer and the moldmaking process in general?

Layo, Dynamic International: All parties have to make sure that they are educated on the new technologies in order to stay current and competitive. The moldmaking process will be much faster and much more efficient, resulting in shortened delivery times. It also affects mold design a little bit - the mold designer can design the tools for high-speed steel cutting where it eliminates some EDM'ing on the tool itself. The design has to be more geared toward the new tooling technology.

Sundberg, TechniDrill: The use of multiple tooling on one machine means that you don't have to move the mold block from machine to machine. The more you can do on one machine the better off you are - especially if it is a large heavy block. So, if we can do the tapping, the counterboring and everything else on the same machine, it makes it more desirable and profitable. I really see no effect on the design process overall.

Beek, Toshiba: These advances will make the whole process much more efficient and will reduce the restrictions that are usually placed on the mold designer. Better tooling will allow the designer to make more complex molds without sacrificing machining speed. And better controls will allow for closer tolerances and less hand finishing.

Garrison, Toyoda: It's tough to get the industry to change their thinking process. Instead of having to write codes for the machining of the graphite and electrodes and things like that, we're trying to get them to increase their efficiency by looking at high-speed machining and hard milling processes. These processes leave a much better surface finish, which reduces polishing time. We can reduce the actual time it takes to make a die or mold by 50 percent. Also, power can be reduced because EDM machines generally use up a lot of energy. We're not claiming to be able to eliminate all EDM machines, but we are claiming to be able to do much of the same work and a lot faster. EDM has many more steps and more programs.

Mann, Yasda: Newer materials used in moldmaking are getting harder and tougher to machine due to higher wear and resistance properties. By being able to do grinding, drilling, milling or tapping at Rockwell 60, we are making the process much quicker. We also can eliminate conventional processes like jig grinding and EDM while still holding critical accuracies.

Related Content

Discover Metalworking Technologies Targeted to Mold Shops

What EDM, automation and machining technologies are currently available to the mold manufacturing industry? MMT has compiled a list of some of the latest.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreSoft Wired: Cutting High Taper Angles with Wire EDM

Examine the wire’s properties to determine the right one for achieving the best cut.

Read MoreMachining and EDM Innovations to Look for at IMTS

MoldMaking Technology previews some of the EDM and machining products and exhibitors applicable to mold builders that will be featured at IMTS 2022.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

_300x250 4.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)