The Heat is On

A survey of the industry reveals what moldmakers have on their hot runner wish lists this year, as well as what new products and technologies hot runner companies predict are going to be "hot" in 2001.

Overall, moldmakers are relatively satisfied with the state of hot runner equipment and components. However, they do have some issues with customer service, quicker delivery times and hot runner suppliers not following mold specifications. In addition, a significant grievance is the fact that there are no uniform standards for hot runner systems. From the other side, hot runner manufacturers and suppliers are trying to address those concerns and help hot runner designers in producing the highest quality parts - both with new product introductions and improving their website capabilities.

The View From the Trenches

Robert Vaughan, senior mold designer for Porex Medical Products (Ontario, CA), a mold builder for medical components and devices, has experienced problems with electrical connections either wired incorrectly or the hot runner supplier not thoroughly examining the supplied prints and following his company's standards. "When this happens, it involves rewiring the connector - which isn't a big deal, but it's something you don't want to have to do because you're paying for it to come in correctly," Vaughan states. "And even though it's not that hard to fix, it can delay things, as you expected it to come in right the first time."

For Peter McInerney, project engineer at West Hatfield, MA-based Wilderness Mold, which builds molds for the electrical connectors, medical devices and telecommunications markets, the problems lie in customer service and delivery. Because of this, they "have been forced to look more closely at competing suppliers and give the local sales reps direct feedback to get to the bottom of the problem."

The same holds true for Trend Technologies (San Jose, CA), a tooling provider that specializes in computer enclosure parts as well as automotive and consumer products. According to Glen Shrigley, general manager for the plastic injection tooling division, delivery times have been their major dilemma. However, the company has come up with a novel way to solve the problem.

"We recently partnered with a major hot runner manufacturer and are working exclusively with them on our hot runners," Shrigley explains. "We've found there's a lot of good hot runner manufacturers out there, but the difference is the leadtime to get the manifolds to us so we can reduce the leadtimes for our tooling. We have typical leadtimes of between six to eight weeks to design and manufacture tooling, so the custom hot runner system has to be built and delivered in less than four weeks. This is where the challenge usually is and most hot runner manufacturers can't deliver in this timeframe."

Luckily, any problems Advance Tool (Blaine, MN) may have been facing have already been solved. According to project engineer Mel Houle, the company is "really familiar" with all of the design criteria surrounding hot runners. "The industry has actually accelerated leadtimes, which was a problem many years ago," Houle comments. "However, that problem has been almost 100 percent addressed. The other issue that came up last year is the ability to get designs really fast. Now all the manufacturers and suppliers have online design help that we use every day, so from our standpoint, the hot runner industry has really come to the plate and helped custom moldmaking people like ourselves out."

Despite Houle's overall satisfaction, there is always room for improvement. "We're still looking for quicker leadtimes and cheaper equipment," he states, adding that hot runner equipment suppliers help out on both of those fronts.

Trend Technologies' Shrigley finds working closely with the hot runner supplier offers excellent benefits. "We're working with our hot runner supplier to develop a valve gate system that will gate right on the cosmetic surface of a part and leave a minimal witness line," he says. "Typically the valve gate systems leave a little ring, so trying to gate right on the surface with a valve gate system becomes quite challenging. The hot runner supplier is developing and building this system at their own cost for us - they see future potential if this manifold system works."

Vaughan of Porex feels that the hot runner suppliers should follow the drawings that are submitted, build the system that way and if there are any questions, ask. "We're held accountable to provide them with the right drawings so they should be held accountable to follow those drawings," he notes. He adds that he would like to see more clarity in the way the suppliers present their information and more uniformity and standardization with all of the manufacturers and suppliers. "I would like the presentations of catalogs and services to be easier to follow and to have a similar layout so that I can feel comfortable that I am preparing my drawings properly, no matter what manufacturer I am considering," he comments.

In agreement is Rick Finnie, president of M R Mold & Engineering (Brea, CA), a manufacturer of compression, transfer, rubber injection, liquid injection and plastic injection molds. "I saw a recent article indicating that SPI was working on developing some standards," he says. "We think that is a very good idea - there should be a standard for everybody to follow."

Finding a variety of hot runner suppliers to work with would be easier if standards were in place. According to Vaughan of Porex, he prefers to work with three or four companies and establish a good working relationship with each of them. "That way, we're not bouncing around every new idea to too many companies," he states. "You need to find suppliers who are willing to listen to suggestions to help meet your needs. Also, good service is a must."

Wilderness Mold's McInerney concurs. "We are starting to look at a wider variety of hot runner suppliers - many of whom give excellent service and have great technology behind them," he says. "They are forever coming up with new ideas and they keep us posted pretty well. It doesn't seem like there's a month that goes by where I don't hear from a new hot runner supplier.

"Explore all of your possibilities - keep your eyes and your ears open, as well as your mind," he adds. "There are a lot of smart hot runner designers and manufacturers out there."

Answering Moldmakers' Needs

Common goals of hot runner suppliers and manufacturers include utilizing current systems and applying them to newer molding applications as well as developing new systems and nozzles to improve color changes with multi-material molding. Here's what the major suppliers had to say about the state of the industry.

What major advancements do you foresee in hot runners this year? How will these advancements affect the moldmaker, mold designer and the moldmaking process in general?

Tony Brusca, president, ALBA Enterprises, Inc. (Rancho Cucamonga, CA) - distributor of hot runner systems, connectors, couplers, three-plate latch systems, hot sprues and temperature controllers: There's been a lot of movement in a lot of directions into both larger and smaller parts. We also see more complicated parts - more of the high-end engineered materials where people want to use hot runner systems in these complicated parts, and it is more difficult to get a nozzle onto the part. Therefore, there's been an awful lot of creativity in applying hot runner systems to some applications that - maybe a year or two years ago - we wouldn't have even been asked to look at. Now everyone is saying, 'Can you do this, can you inject this; and this is where we need to inject it,' so we're seeing a lot more complicated applications as well as more and more of the high cavitation. Another area that's growing is two-material or two-color molding, as well as TPEs [thermoplastic elastomers] and TPRs [thermoplastic rubbers]. Quick color changes also are a big deal, and nozzles are coming out that are designed for quicker color changes and that also offer the ability for some maintenance to be performed in the mold. If you have a special nozzle, you have to design the mold to accommodate the nozzle.

Ken Kurtz, product manager for hot runner systems, D-M-E Company (Madison Heights, MI) - manufacturer and distributor of hot runner systems, mold tooling, mold components and electronic controls: One of the major advancements that will help the industry lies in the ability to interact with customers on the Internet. We are in the process of improving our web capabilities so that CAD designs will be able to be downloaded, which will improve the speed of projects getting started and completed. The Internet is a big trend right now - it's easier to do business on the Internet, the information can flow faster by way of downloads and the 24/7 access gives you a high degree of convenience.

Dirk Vander Noot, vice president, Gunther Hot Runner Systems, Inc. (Buffalo Grove, IL) - hot runner systems manufacturer and service provider: I really don't foresee any breakthrough technologies in hot runners this year. A major advancement will be how hot runner designs will be implemented through the Internet via a website. It will be much easier and faster for a designer to complete their mold design through this technology, especially in 3-D applications.

Martin Baumann, marketing manager, hot runners, Husky Injection Molding Systems, Inc. (Milton, VT) - hot runner equipment manufacturer and supplier of hot runner technology: We see an increased interest in multi-material molding and hot runners play a key role in this technology. From a hot runner point of view, this presents some design challenges in regards to the layout of the systems - making sure that the system is configured correctly for the application. With multi-materials, you don't necessarily need completely different nozzles; it's just how the system is configured. For example, if you have three materials, you need three different manifolds in one hot runner system. So, the challenge is designing the layout, making sure that there's enough support in the plates to ensure that the mold is very rugged and addressing the fact that there are significantly different part weights. Therefore, from a design point of view, the system is more complicated. It's pretty much known technology, it's just how you package it that can be challenging.

There also is a renewed interest in doing even smaller parts with the direct gating rather than cold runners or hot/cold combinations. Sales of our smallest nozzle have been strong and the driving force behind that is basically to reduce resin consumption and molders looking for faster cycle times to get more productivity out of the molds.

What developments are underway within your company specifically in regards to hot runners?

Brusca, ALBA Enterprises: We've come out with a line of KS nozzles, which are designed for quicker color changes. We also design custom nozzles that will allow us to help customers with their particular problems or materials. We're just trying to meet our customers' needs with all of these new applications and anticipate where the market is going, but at the same time we're not trying to drive it. We also want to position ourselves for the commodity materials - the cap and closure industry, for example.

Kurtz, D-M-E: New from D-M-E are HTS hot runner systems, which we distribute worldwide. This product line is primarily focused on edge gate technology and we have developed standard manifold layouts for 2 x 2 through 2 x 16 gate configurations. All of these standard manifolds have a balanced flow path, which means equal flow lengths and diameters to each gate to enable part consistency. The ability to edge gate directly from a manifold is unique to this design and output can effectively be doubled with the same size mold base.

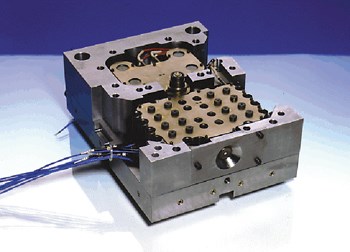

Stellar hot runner systems are externally heated and designed for micromolding. These systems can handle challenging engineered materials - including high-temperature crystalline resins - that are ideal for the electrical, electronic, medical and packaging markets.

Vander Noot, Gunther: The developments underway with Gunther Hot Runners is the continuation of miniaturization of the hot runner system, namely smaller pitch centers and stack heights for valve gate systems. We also are working together with the resin suppliers in developing hot runner systems for MIM (metal injection molding) and ceramic applications.

Baumann, Husky: We are introducing the 500 series nozzles - a small nozzle. It allows valve gating with a one pitch, nozzle-to-nozzle spacing. We also have just introduced a nozzle tip that has a mixing function right in the tip before the melt enters the gate. It improves color change and delivers a more homogenous melt to the cavity. A tip like this has never been available in this industry although there have been attempts to do things like this.

|

|

Related Content

Considerations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreRead Next

Hot Runner Justification

How OEMs, molders and moldmakers can better determine when it makes sense to use hot runner technology.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)