Testing the Waters With Multi-Material Molding

This shop’s sampling capabilities enable customers to take a step-by-step approach to these applications without the risk and expense of purchasing a dedicated press.

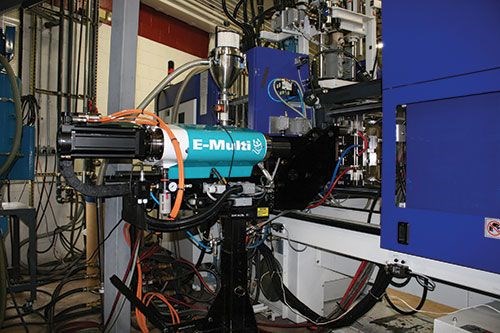

Capability to mount horizontally to the mold enables E-Multi users to mimic a wide variety of injection press configurations.

About three years ago, one of Accede Mold & Tool’s long-time customers asked for guidance on producing multi-material parts for an OEM further up the supply chain. The customer had only single-shot presses, and although it was interested in adding multi-material capability, it couldn’t justify the expense. After consulting with Accede, the customer realized it wouldn’t have to.

Thanks to an auxiliary plastic injection unit that fits vertically or horizontally onto any standard press, Accede was able to develop a process to produce the part using the customer’s existing equipment. In a scenario that’s since been repeated many times over, the customer is still using that process—and that unit, an E-Multi system from Mold-Masters—to this very day. Read this case study to learn more about the unit’s effect on Accede’s sampling and validation operation.

Related Content

-

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

-

How to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

-

Quickly Troubleshoot New Molding Defect with Moldfilling Software

SyBridge Technologies analyst compares original, new Moldflow process simulation results, solves molding defect without tool needing to be taken out of production.

.jpg;maxWidth=970;quality=90)

_300x250 3.png;maxWidth=300;quality=90)