Tech Trends: On the Cutting Edge

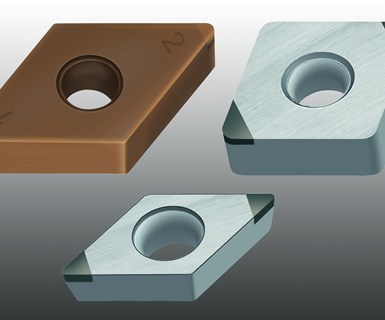

This collection of highlighted cutting tools products offer complete solutions for machining processes from companies like Walter, Seco, Big Kaiser and Tungaloy.

Keep in the know about recent mold manufacturing with a review of recent products and services announcements from MoldMaking Technology’s comprehensive list of supplier companies.

Cutting tools are used on machine tools to cut metal, and are one component of the overall mold machining process to consider when looking to improve speeds, feeds, wear and surface finish. This week, we look at some highlighted cutting tools, which range from products that can help with finishing high-temperature superalloys in either continuous or interrupted cuts, handle both roughing and finishing operations effectively in all material types, enable access to clean fixturing surfaces and quick setup changes or make fine adjustments possible.

Interested in More on Cutting Tools?

Be sure to check out the Cutting Tools Zone for the latest articles, blogs, products, news and videos.

Browse our entire database of moldmaking products in the products section. You can browse to stay updated on the latest product offerings, or search for specific product information based on categories.

Related Content

Considerations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreForces and Calculations Are Key to Sizing Core Pull Hydraulic Cylinders

To select the correct cylinder, consider both set and pull stroke positions and then calculate forces.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)