Products

Mold Solutions Target Safety, Storage and Productivity

NPE2024: Globeius and its suppliers showcase solutions focused on decreasing downtime, reducing energy consumption, increasing safety and more in an injection mold shop.

Read MoreMolding Equipment Features More Connectivity With Robots, Auxiliaries, Industry 4.0

NPE2024: Wittmann USA showcases five injection molding machine work cells, integrated with robots, auxiliaries and 4.0 technologies to highlight their efficiency and sustainability.

Read MorePlant Software Enhances Real-Time Condition Monitoring

NPE2024: MiVue, a division of the ACS Group, is showcasing expanded capabilities for its plant monitoring software for plastics processors.

Read MoreOptical System Delivers Rapid Machine Vision Solutions

NPE 2024: The VS Vision System by Keyence incorporates fast setup time and built-in AI to ensure for quick inspection and real-time data visualization.

Read MoreMaintenance Products, In-Booth Demonstrations Highlight Mold Cleaning

NPE 2024: iD Additives is featuring live, in-booth mold cleaning demonstrations using its Eco-Pro 360, in addition to an exhibit of its other mold cleaning solutions.

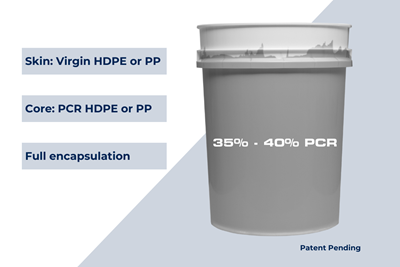

Read MoreCo-Injection Mold Design Blends PP and PCR Materials

NPE2024: Co-injection mold technology by Top Grade Molds promotes environmental sustainability, without compromising quality or performance.

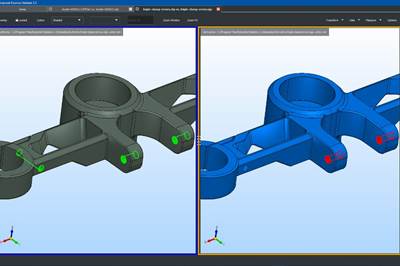

Read MoreValidation Software Enables Efficient Translation of CAD/CAM Data

Verisurf CAD/CAM, now providing access to Kubotek Kosmos Validate software, is designed to ensure data integrity and enable users to perform metrology workflows in a seamless CAD environment.

Read MoreState-of-the-Art Machines, Custom Manufacturing to Reduce Injection Molding Waste

NPE 2024: Sodick-Plustech, Matrix Tool and RJG are highlighting injection molding machines, custom tool and molding capabilities and an AI-powered interface, respectively.

Read MoreSurface Roughness Tester, Software-Supported CMM Simplify Moldmaking

NPE2024: Mitutoyo America addresses increasingly complex mold design testing with SJ-210/SJ-410 surface roughness testers and the MiSTAR CMM, geared toward inline automation.

Read MoreMoldmaker Showcases Molding Equipment for LSR, Injection Molds

NPE2024: M.R. Mold showcases its proprietary line of products for liquid silicone rubber (LSR) and plastic injection molds alongside four industry partners.

Read MoreValve Gate Nozzle Enhances Direct Side Gating Capabilities

NPE2024: Ewikon is introducing the pro Edge VG range which sets new benchmarks in terms of ease of maintenance, gate quality and flexible use.

Read MoreProduction Tracking Software Enables Smart Factory Functionalities

NPE2024: Wintriss is demonstrating the advanced features behind its ShopFloorConnect software and ShopFloorTracker hardware, key to capturing, tracking and managing data collection.

Read More

_300x250 1.png;maxWidth=300;quality=90)