Striking a Balance with Global Production

Due diligence and the right business model gives Burteck the flexibility to reap the rewards of overseas mold manufacturing while limiting potential drawbacks.

When asked what makes plastic injection mold manufacturer Burteck “tick,” Program Manager John Eastham doesn’t hesitate. “It’s the people,” he says. “We’re a group that loves plastics. We’re passionate about manufacturing, and we want to see it grow in the U.S.”

Coming from a representative of a company that sources approximately 60 percent of its production from China, such a statement might seem disingenuous on the surface. Nonetheless, Eastham insists that Burteck is doing its part, noting that its domestic production has increased approximately 30 percent since the company was founded a mere four years ago and continues to increase. Constructed just last year, its 16,000-square-foot, fully outfitted moldmaking facility is a relatively new addition to the Windsor, Connecticut, community, one that provides gainful employment for 18 people, including eight seasoned toolmakers. Given that Eastham’s most significant immediate-term worry is coping with what he calls “an enormous amount” of quoting activity, Burteck could very well continue its robust growth—and its contributions to the U.S. economy—for some time to come.

Eastham readily admits that, in isolation, patriotism and passion for manufacturing couldn’t have brought the company to where it is today. From the very outset, Burteck’s success has been driven by a recognition that business in the modern era is global. The company was set up to take advantage of the cost savings that come with sourcing tools overseas, and he doesn’t anticipate that its basic business model will ever change. However, that business model isn’t what most people envision when they think about offshoring, he says. In fact, it’s the reason behind his claim that even the most discerning customers can’t tell whether a mold was produced in China or at the company’s Connecticut plant. What they do see is less expensive tooling, shorter lead times, and the convenience that comes with sourcing high-quantity mold packages from a single supplier.

Taking Ownership

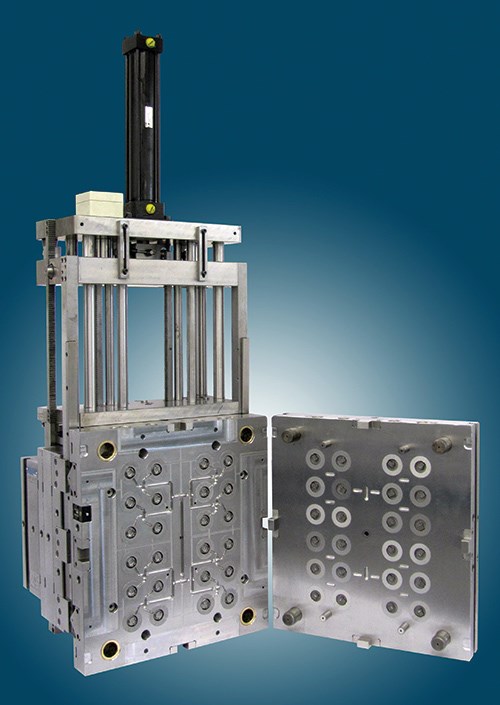

When company President Peter Burgess founded Burteck in 2010, he and his team recognized that the company’s relationship with overseas toolmakers would have to differ from traditional arrangements. For one, Chinese tools have a reputation in this country for not performing as intended. Beyond that, the company chose to specialize in Class 101, high-cavitation tooling characterized by tight tolerances, complex geometries, hot manifolds, two components, and complex, moving parts like slide actions and unscrewing devices.

Given these challenges, going through a broker—salespeople who are typically paid on commission to represent multiple manufacturers—would never work, Burteck’s leadership reasoned. Although working directly with a toolmaker would keep costs lower, even this traditional customer-supplier relationship wouldn’t be enough for Burteck’s purposes. The company needed control. So, leadership instead opted for a formal business partnership with a firm that operates two separate toolmaking facilities in the Shanghai area.

Having an actual ownership stake in the Chinese toolmakers goes a long way toward ensuring their priorities match those of the U.S. operation, Eastham says. “We’re not a customer of this company. They have a stake, too,” he explains, noting that the relationship offers the flexibility required to accommodate urgent work. In fact, Burteck maintains a dedicated team based in China to facilitate better coordination on tooling that ships to the U.S., all of which is designed at the Connecticut headquarters facility. The team also oversees quality control and sampling operations (the latter of which are often videotaped).

Due Diligence

What Eastham calls “due diligence” on U.S.-bound tools doesn’t stop with the team in China. Upon arrival in the U.S., each and every mold goes through a stringent checklist to ensure it meets customer specifications. Surface finish, vents, gate sizes, manifold heating zones—virtually every aspect of every tool is thoroughly checked and documented, Eastham says. Other steps common to every build include hanging tools by a lift strap to ensure they’re level and spotting to ensure proper operation.

A Flexible Approach

As word of mouth about Burteck spread during the past four years and business increased, the company continued to ramp up its capabilities in the U.S., a trend that continues today. During the past few months alone, Burteck has hired an apprentice and added three new machine tools (a Haas VF 2YT VMC, as well as a Mikron HSM 500 LP VMC and an AgieCharmilles sinker EDM with carousel electrode changer, both from GF Machining Solutions).

A number of factors account for the ramp-up in domestic capability. Certain work, such as a new market in micromolding, requires capabilities that aren’t available in China. (The company plans to showcase its capabilities in this area at the NPE show next month.) Beyond that, economic forces driving the widely heralded reshoring movement have made manufacturing in the U.S. more attractive, Eastham says. In fact, some customers are even willing to pay a bit more for a tool that’s fully machined and assembled here at home.

Yet, despite recent trends, the flexibility that comes with an overseas partner is just as advantageous as ever for the growing company, Eastham says. That’s because Burteck can flex capacity as needed according to the requirements of the job. “If we’re quoting a 15-mold package, we know we can do the whole thing,” he explains. “Having all the equipment and staff you need domestically just isn’t feasible sometimes.”

This capacity flexing is often more complicated than choosing to manufacture here or there. For example, one recent job involved roughing in China and finishing in Connecticut to complete the build before the holiday season. Whether due to timing considerations, particularly complex tooling, stringent surface finish requirements or other proprietary concerns, opting for a “hybrid build” can enable faster turnaround than would be possible otherwise.

Regardless of where the work is performed, Burteck’s chief priority is ensuring that all tooling carrying its name is held to the same high standard. As long as it meets that goal, a careful, strategic approach to global production can help adapt to whatever the future has in store.

“The philosophy of ‘USA or bust’ is a very narrow-minded point of view,” Eastham says. “I think people who bang their fists on the table and say ‘This way or no way’ are missing opportunities. The proof of that is where we are today.”

Related Content

Ceramic Deburring, Deflashing Tools Take Into Consideration Difficult Materials, Operator Safety

Boride Engineered Abrasives introduces its new mold polishing equipment, the Work Finisher Tool, which is lightweight, long lasting, won’t rust and is safer and easier to use.

Read MoreFAQs: What Are the Leadtime Leader Awards?

Here are answers to some frequently asked questions about MoldMaking Technology's annual Leadtime Leader Awards competition.

Read MoreMMT Chats: Project Engineer Applies Lean Manufacturing Principles to Growing Sustainability Role

MoldMaking Technology Editorial Director Christina Fuges catches up with MMT’s 30-Under-30 Honoree Katherine Pistorius, who has added Regional Sustainability Coordinator alongside her Project Engineer duties, which demonstrates the many paths one can take in a manufacturing career. Here she shares how this opportunity unfolded for her and what the job entails today and in the future. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreVIDEO:"The Smith Boys" on How Moldmaking is an Innovation Machine

"The Smith Boys" AKA President of DME Peter Smith and Director of Sales, Scott Smith discuss why the moldmaking industry is an innovation machine and how it is crucial to remedying global supply chain issues.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)