Staying One Step Ahead of Customer Needs

The key to optimal customer support for any mold manufacturer is doing more—from upfront design engineering during the initial stages of product development to emergency mold repair services. And this is exactly the business model Kansas City-area blow moldmaker Creative Blow Mold Tooling offers.

Share

The key to optimal customer support for any mold manufacturer is doing more—from upfront design engineering during the initial stages of product development to emergency mold repair services. And this is exactly the business model Kansas City-area blow moldmaker Creative Blow Mold Tooling offers to stay ahead of its customers’ needs.

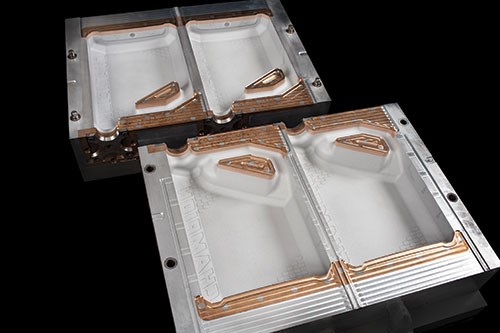

Creative began building this model in 1984 when the company was established to design, manufacture, repair and reverse-engineer blow-mold tooling for the plastic container industry. Today, the company’s plant in Lee’s Summit, Missouri accommodates mold manufacturing for wheel, shuttle, injection stretch blow mold and reciprocating screw platforms. This provides the necessary flexibility for the company to meet its customers’ diverse and changing needs, and also helps to maximize Creative’s productivity and manufactur-ing processes.

“In our operations, we couple upfront design efficiencies with lean manufacturing techniques to maximize throughput that generates an effective value stream and reduces lead times. This allows us to meet our customer’s scheduled deadlines,” explains Jim Hensiek, director of business development.

The “Doing More” Model

Hensiek believes success comes from being different and willing to do more for the customer than just building tools, and that is why Creative invests a significant amount of time and resources in working with clients on front-end design, some of which it doesn’t get paid for.

“It’s all about the relationship,” Hensiek says. “We collaborate with customers on a variety of issues, many times before a project has been approved. Once the tooling is built and delivered, if a customer needs us on site to assist with run-off or other issues, we commit our people there the next day. Staying in touch with our customers, being good listeners and helping them meet their internal company goals have earned us their confidence. This ‘trust factor’ is essential to becoming a preferred vendor in their supply chain.”

With Creative already focused on customer plant productivity, quick turnaround and communication, the logical next step in the company’s business model was to initiate a 24-hour emergency blow mold repair service. According to Hensiek, this means that technicians give immediate attention to molds when they arrive at the dock via a series of tests to determine the severity of the damage. This information is then communicated to customers and turnaround time is defined, putting everyone on the same page with regard to expectations. Once the repair work is complete, the customer is contacted and the mold is returned to the plant.

The Team

To successfully accomplish Creative’s goals, 35 employees are split among three shifts that cover 24 hours a day, five days a week. According to Hensiek, this team approach ensures that a customer’s product is built right, every time, on time—shortening the customer’s supply chain.

This team has evolved through an ongoing effort of recruiting and developing dedicated and knowledgeable people to service the customers. Team members possess a long history on both sides of blow molding: experience in plastic packaging plant operations, and expertise in mold design and manufacture. Since this caliber of employee is tough to find, Creative has focused on local high schools, personal relationships and referrals for these new hires. Once on board, each employee is quickly oriented to Creative’s processes and methodologies.

Hensiek says the company strives to live up to its core values every day. These values include:

• Customer focus. Creative says it is passionate about serving the needs of its customers, whose success is a key measure of Creative’s success.

• Teamwork. The company encourages collaboration within the team as well as with its extended team of customers and suppliers.

• Respect. Creative says it strives to treat everyone with respect and dignity, recognizing that innovation comes from considering unique perspectives.

• Integrity. The company also says it strives to be honest and ethical in everything it does, without compromise.

• Excellence. Creative recognizes that, in order to grow, it must learn, adapt and embrace change through continuous improvement.

“We treat people the way we want to be treated,” Hensiek explains. “We foster a team environment where everyone can express their opinion and be confident that their ideas will be considered. We have open communication with our team members as to company performance, new projects in the pipeline, next quarter outlook and issues of importance within the business beyond the work performed each day.”

Creative is also fortunate to have close access to community college training opportunities through which employees can expand their knowledge base. The Metropolitan Community College Business and Technology Center in Kansas City offers a variety of classes in CNC machining, CNC programming, lean manufacturing, design for Six Sigma, and supply chain and operations management.

Creative also participates in a consortium of local manufacturing companies that commit to hiring students as interns at the end of each semester. These interns have become a source of new talent for the company.

“Some of our employees have reached a level of expertise that qualifies them to teach these same courses, which can be done adjacent to work schedules,” Hensiek says. Creative also offers online and e-learning opportunities, including training through its memberships in the AMBA and NTMA.

The Technology

Along with a commitment to quality personnel is a significant commitment by ownership to capital expenditure investment. In 2009, Creative increased the size of its Lee’s Summit facility, adding 10,000 square feet for additional equipment and an expanded inspection room.

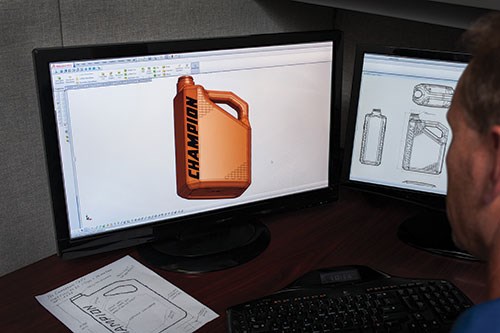

In addition, a blend of 19 vertical and horizontal machining centers gives Creative the capacity to take on short-turn projects. By setting up and running multiple components simultaneously, Creative is able to eliminate wait time for completion of certain components prior to mold assembly and inspection. The company also stocks certain new mold components based on customer demand, reducing the setup and machine time required to build a finished part. A new DMG Mori Seiki vertical high-speed machining center and an additional Haas horizontal machining center are two recent additions to the company’s machine line up. When it comes to software, Creative’s enterprise resource planning system integrates SolidWorks, Pro/E and AutoCad for design, and Mastercam for programming. Shoptech’s E2 helps to manage the production schedule and job costs.

All of this investment has re-positioned Creative with its current customers, increasing its capacity to take on more project opportunities while continuing to meet manufacturing schedules and project deadlines.

“Now with the additional production capacity and market confidence in our ability to deliver, we can build new market relationships, adding market share in the extrusion blow molding (EBM) and two-stage injection stretch blow molding (ISBM) markets,” Hensiek says.

Creative knows that its goals require ongoing investment in people, technology and processes. The company continues to be committed to remaining lean and highly productive to meet customer requirements and compete for new work.

Related Content

Questions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreMaking Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreConsiderations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)