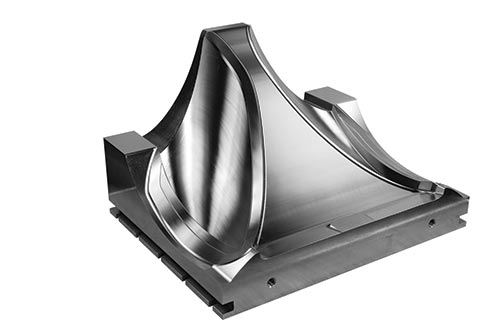

Smooth Surfaces without Hand Finishing

Advances in NURBS functionality speed up cycle times, meet high-accuracy finish requirements and allow molds to be completed on the machine.

Many moldmakers consider post-production work and hand polishing to be a fact of life. After weeks of work creating the mold, its surface is often not smooth enough when it comes off the machine, and it requires manual labor to finish it properly. Manual labor consumes time, and it’s becoming more difficult to find qualified (and willing) workers to complete this work. In addition, the costs associated with this work are a source of an ongoing frustration and a profit-killer.

It doesn’t have to be this way, however. There is advanced NURBS technology that can enable molds to be completed on the machine and eliminate hand finishing.

NURBS is an acronym for non-uniform rational basis spline, a technique that was developed in the 1950s as a mathematical way to regenerate freeform curves and shapes such as car bodies and ship hulls. It is commonly used in CAD software packages along with CAM systems and is part of industry standards like CAD files. But even when typical NURBS technology is used, hand finishing is still necessary to produce the required smooth finish.

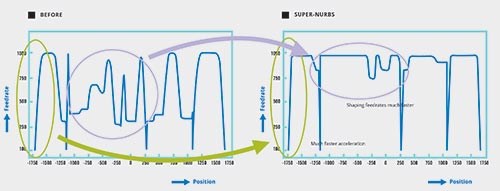

With complex curvature shapes, a CAM system will output a series of X, Y and Z points (in a three-axis example) and create the curve using piecewise linear movements. In order to generate the curve, it will actually utilize many small linear movements. When left in that form, the control will attempt to drive to each individual point and ask for confirmation of its intended destination as part of the feedback processing loop.

The machine may never actually reach its programmed speed because it can only crunch so much data before it has to start slowing down to maintain the feedback loop and keep the programmed accuracy. Machinists and programmers cannot improve on this scenario by using NURBS that has been standard in the industry, because the control decides how fast it can go while maintaining the point-to-point accuracy of the shape.

A New Approach

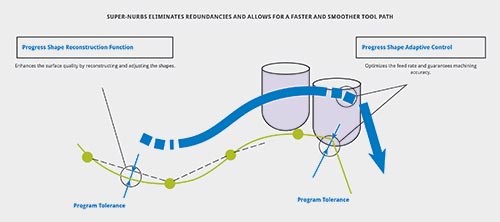

With advanced NURBS functionality, however, the control projects a tolerance band that is predetermined by the programmer through the series of points. Based on this, it will create a spline that is a “best fit” and may eliminate some of the points that are redundant to the spline path, allowing for a smoother tool path. And because some of the points are eliminated, the positioning feedback does not need to crunch as much data and can speed up the movements while still maintaining accuracy (see Chart 1). Benefits of this approach include elimination of redundancies, resulting in a faster, smoother tool path; high-quality surface finishes on the machine; ultra-high feed rates due to faster control loops speed; and parts out the door faster with better finish quality and accuracy.

Fine Functionalities

Today, there are advanced NURBS technologies that perform so well that molds can be finished on the machine. Here are five functionalities to look for that, when combined, make costly hand finishing a thing of the past. As an added benefit, these functionalities will also significantly speed up cycle times while still meeting high-accuracy finish requirements.

1. Advanced Control Functionality. Look for a control that functions by projecting a predetermined tolerance band and creating a spline considered to be the best fit for the job. This eliminates redundancies and allows for a faster and smoother tool path (see Chart 2). With less data to crunch, movements are sped up while maintaining a high level of accuracy to generate high-quality surface finishes.

2. Faster Control Loops Speed. The feedback loop determines how quickly the machine can “talk” to the encoder and servo units. Look for NURBS technology through which the machine more quickly tells the servo where to move and receives confirmation that information has been received. This enables more ultra-high feed rates to be used.

3. Digital-to-Digital. While controls are digital, many machine tools in the industry still use analog data, which requires translation activity that slows down the machining process. Look for

NURBS technology that employs a digital-to-digital control loops feed that speeds up the communications process and enables faster machining. With this technology, there’s no need for a look-ahead, because the system is inherently fast without it.

4. Machine Build Quality. The build quality of the machine can enhance the overall functionality and effectiveness of NURBS technology. Look for features such as ribbed castings for strength; a large base casting with three-point leveling; integrated ballscrew mounts to ensure rigidity; a cantilevered column to reduce weight and resist bending; hand-scraped cast mating surfaces for superior flatness and contact; and a work area enclosed in sheet metal to prevent hot chips and coolant from contacting castings, which minimizes thermal influences.

5. Mechatronics. Look for a machine that is built as a complete, integrated package, where the machine and control are made by the same builder. This approach means the mechanical and electrical are blended to assure optimized communication between the machine and its control. These advances can only be achieved by using a mechatronics approach that unleashes the full potential of your machining processes.

The right NURBS functionality can help mold manufacturers achieve controlled, high-speed, high-quality machining; faster roughing speeds; better surface finishes; and parts completed on the machine.

Related Content

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreThe Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreRead Next

Rethinking Three-Axis Capabilities

Ballnose cutters don’t necessarily require five-axis machining routines to impart fine surface finishes that don’t require hand polishing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)