“Smart” Technology Boosts EDM Efficiency, Quality

Three EDM innovations showcased at GF Machining Solutions’ recent “Solutions Days” open house have one thing in common: they automatically adjust generator settings according cutting conditions, operator preference or both.

AgieCharmilles-brand sinkers like the Form 300 incorporate the Intelligent Process Generator (IPG), which forms the basis for the new developments detailed below. In essence, this roughly decade-old technology works by generating less-powerful sparks with shorter on-time to reduce the risk of degrading the surface without sacrificing speed.

How much would your customers appreciate an EDM’ed mold surface that’s virtually guaranteed to release plastic without any sticking? How much would your EDM programmers appreciate technology that removes much of the tedium and guesswork associated with configuring the process? What about the ability to use even smaller electrodes for particularly complex mold features? Based on what I saw on the morning of June 19, all of this is already reality.

That Friday was the last day of "Solutions Days," an open house event at GF Machining Solutions’ U.S. headquarters facility in Lincolnshire, Illinois, and staying in Chicagoland an extra day after the conclusion of Amerimold 2015 was well worth it. Although innovations on display ranged from automation to milling to laser texturing and even software and other technology from supporting partners, my discussions at the event were dominated mostly by the aforementioned EDM developments. Here’s a quick overview:

3DS. The latest of the company’s EDM innovations, 3DS builds on the success of the Intelligent Process Generator (IPG) that has long been a standard feature of most of the company’s AgieCharmilles sinkers. After extensive experimentation with the generator, the company has zeroed in on particular combinations of settings to achieve surfaces with far less friction. As a result, plastic parts are far less likely to stick to the mold surface.

Notably, a surface generated with 3DS isn’t necessarily any smoother—at least, not in terms of the roughness average (Ra) value. For most molds, the “sweet spot” is about 0.2 Ra, and 3DS technology typically has no effect on that measurement, explains Eric Ostini, product manager at GF Machining Solutions. Rather, 3DS adjusts root mean square (RMS), a different formula.

To explain the difference in practical terms, he compares how two hypothetical mold surfaces, both with the same Ra value, might look under a microscope. The surface generated without 3DS resembles a bed of gravel, while the one generated with 3DS looks more like a closely compacted group of lily pads. That is, the average height across the microscopic peaks and valleys are the same on each, but those peaks and valleys are spaced further apart on the 3DS surface. Taking advantage of 3DS requires simply selecting the desired setting, and the CNC software does the rest.

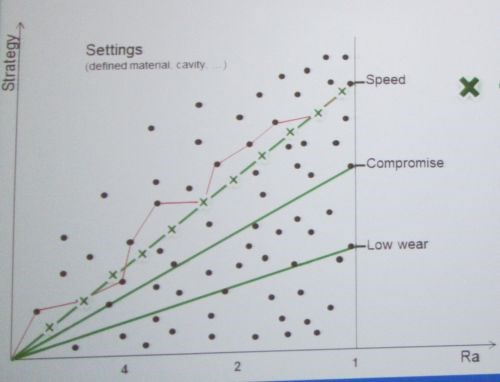

Techform. 3DS isn’t the only example of generator settings and control software combining to enable faster programming and better parts. Techform technology enables users to select a generic compromise between burn speed and electrode wear based on the priority for any given job, and the CNC adjusts power supply settings accordingly, says Gisbert Ledvon, director of business development.

Techform smooths the transition to different generator settings during the progression of the burn according to the user's priorities (in this case, speed, as indicated by the broken green line). Like a driver shifting gears, this avoids abrubt transitions (red line).

This occurs throughout the duration of the cut and responds to changing conditions, thereby reducing the need for an operator with the expertise (and the time) to manage the intricacies of amperage, voltage, on/off time and other such settings. It also leads to a more stable process, Ledvon explains. For instance, spark power should decrease as an orbiting electrode moves closer to a sidewall. Techform ensures that this not only happens, but that the transition is smooth—that power is adjusted in increments rather than jumping straight from one setting to another. “It’s like driving a car,” Ledvon says. “Gears 2 and 3 smooth the transition from 1 to 4,” he says.

iGap. Yet another generator advancement, iGap alters the discharge current and pulse duration in real time to improve cutting speed and reduce electrode wear. This is particularly useful for small, intricate burned features, Ledvon says. Electrodes must typically be machined slightly undersized to effectively burn a cavity feature. iGap enables using more power and, thus, faster cutting speeds, even with small undersizes. This is of particular benefit to shops using very small electrodes, and it could even enable the use of smaller, more intricate electrodes than would otherwise be possible. Like 3DS and Techform, this capability can be easily selected in the machine’s Form HMI CNC touchscreen interface.

For more on technology from GF Machining Solutions, visit the company’s website.

EDM certainly wasn't the only highlight of the event. The texture visible on the top of this model head was created via laser texturing, a technology that could be catching on for imparting leather grains and other surfaces on automotive industry molds. Read this March-issue feature article to learn more.

Related Content

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreForces and Calculations Are Key to Sizing Core Pull Hydraulic Cylinders

To select the correct cylinder, consider both set and pull stroke positions and then calculate forces.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MorePlastic Prototypes Using Silicone Rubber Molds

How-to, step-by-step instructions that take you from making the master pattern to making the mold and casting the plastic parts.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)