Technology Tuesday, Everything Additive

I began working on Additive Manufacturing magazine back in 2012 with the publication’s chief editor, Pete Zelinski. Since then I’ve covered several facets of AM technology, but mostly those relevant to mold and toolmaking. Here, I revisit some of the applications and processes discussed.

Additive Manufacturing is a magazine focusing on the use of 3D printing technologies to make functional products such as mold tooling and end-use parts. Some of the processes and applications of particular interest to mold manufacturers include conformal cooling, metal laser sintering hybrid milling, 3D printed tooling, 3D printed jigs and fixtures, repair and safety, to name a few. Here are some of the stories I produced over the past few years. I believe they are worth a first, or second, look.

1 A traditional mold manufacturer or injection molder can and should embrace additive manufacturing, because it is truly complementary to its existing processes and adds value, says VistaTek.

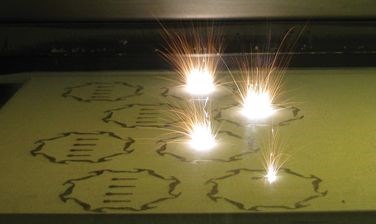

2 Repairing damaged mold inserts is a growth area for additive manufacturing, particularly for direct metal laser sintering (DMLS). Rather than replacing damaged tools, DMLS can be used to quickly repair only the damaged areas, resulting in simplified repair, decreased downtime, longer operating life and reduced costs associated with maintenance and repair, according to Ecoparts and Innomia.

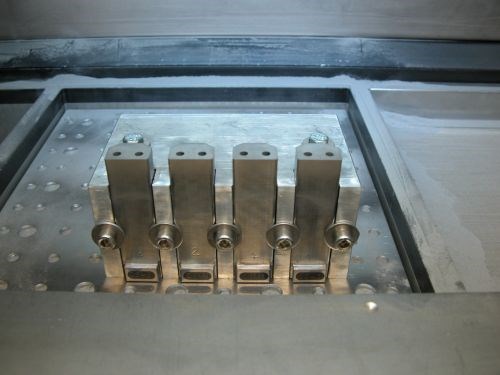

3 LMD, which can be used to make the pinch-offs, differs from other related AM processes in that it works with multiple materials, not a single material. Rather than machining a pocket to accept a wear insert, a shop machines a recess to accept LMD material that becomes one with the substrate (the mold), meaning there is no thermal break. The bottom line is, with LMD in blow mold manufacture and molding shopscan replace the standard generic pinch-off inserts, and build a mold without any sections at all, providing enhanced benefits to the molder and moldmaker, according to Garrtech.

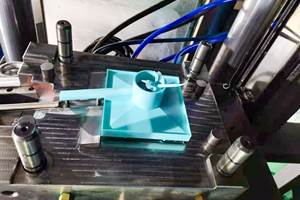

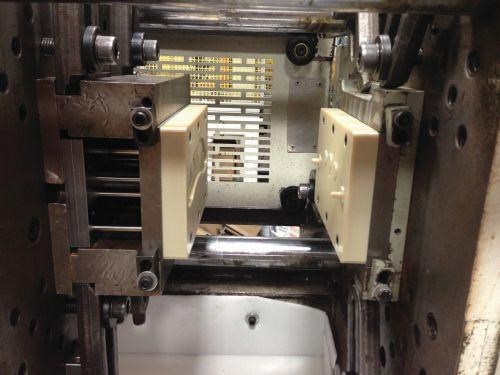

4 On the moldmaking side, Premier has used 3D printing via the Stratasys machines’ fused deposition modeling (FDM) process to run off prototype mold tools for a customer, printing the molds from Ultem and then creating a master unit die (MUD) set. After printing A and B halves, the company successfully ran 30-40 polyethylene parts for the customer using this tooling. Making low-volume injection molds in this way has helped the company win work from customers unable to justify $5,000 for a first run of molded parts.

5 The most important benefit of 3D sand printing, according to Ford, is the speed of the process. If you look at the traditional way of making a casting, you are months out before you get your first casting, and with 3D sand printing you can have a casting in a matter of days to a couple of weeks.

6 With proper training and a clear understanding of the handling and storage of powders, as well as static electricity and flammability risks and pathways of exposure, additive manufacturing safety can be easily and effectively implemented, according to UL AMCC.

7 Currier realized the importance of recognizing a customer’s expectations of its additive manufacturing capabilities to prevent communication breakdowns and part failure down the line. The company learned how valuable it is to understand the customer’s functional expectations for the part, so they can educate the customer as they go. Many customers do not fully grasp the design for manufacturability (DFM) process, especially as it relates to tooling design and mating components. They take the time to help the customer understand the complexities of form, fit and function.

8 Harbec’s sweet spot is complexity. While using additive to make simple parts is cost-prohibitive, the technology tends to offer an advantage for producing complex parts in lower volumes. “Complex parts and tooling are expensive, but AM helps us look at that differently,” Schneider says. “It makes complexity not such a big hurdle, and it also doesn’t have such a cost attributed to it. It’s more about total part volume than complexity.”

Related Content

MMT Chats: California Mold Builder Discusses the Difficulties with Silicone Molding and the Power of the Magic 8 Ball

MoldMaking Technology Editorial Director Christina Fuges sits down with M.R. Mold President and Owner, Rick Finnie, to discuss how he began his moldmaking career, M.R. Mold's LSR Education, and the struggles of working with silicone. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreVIDEO: How Molds Make Life Happen

Hasco America Inc.'s Engineering Manager, Brenda Clark, brings her lifelong expertise to our MoldMaking Technology audience by shedding light on new innovations, what skills are needed to be successful in the industry and how Molds Make Life Happen.

Read MoreA 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.

Read MoreEvaluating Metal Powders for Conformally Cooled Mold Inserts

Mechanical properties and design software techniques reveal the benefits of a modified high thermal conductivity metal powder for 3D printing in moldmaking.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

_300x250 4.png;maxWidth=300;quality=90)