Simplifying Mold Design

Self-locking cylinders enable movement of sliding cores without the need for heel blocks or additional cylinders. This allows for a smaller mold base, less complex mold design and reduced material costs.

Mold manufacturers face many challenges in building molds. Doing as much as possible in as small a space as possible is often the goal, but making necessary movements within the mold can be difficult. Sliding cores pose this type of challenge because they can require additional components and therefore larger mold bases.

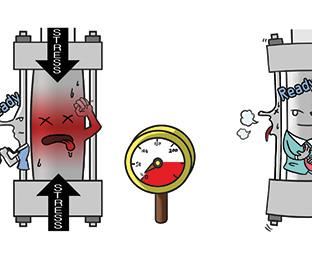

Some of the more common methods of moving and holding a sliding core in position are angle pins, horns, heel blocks (wedges), and pneumatic or hydraulic cylinders. It can be difficult for cylinders to hold position against high injection pressures, however. Sometimes coupling the cylinder with check valves close to the mold can resolve this problem, but depending on the amount of injection pressure necessary to fill the part, a standard block cylinder with a very large bore size may be required. This type of cylinder, of course, takes up valuable real estate within the mold.

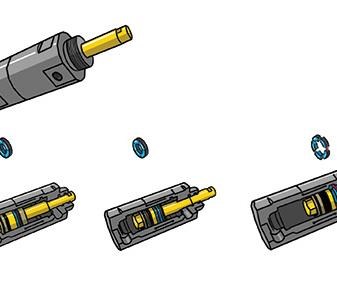

A hydraulic self-locking cylinder, on the other hand, enables independent movement of the sliding core and completely eliminates the need for wedges. It accomplishes this using a multi-taper, segmented ring that, while in the open position, fits tightly into a groove inside the cylinder body on one side and pushes against a shoulder in the rod on the other side. A taper cylinder piston keeps the ring in position. As a result, the plastic injection pressure from the part cavity pushes against the segmented ring, instead of straight hydraulic pressure, locking the slide without the need for a heel block. Avoiding the use of heel blocks or additional cylinders enables the use of a smaller mold base, which can lead to simplified mold designs and reduced material costs.

To illustrate the holding forces possible with a hydraulic self-locking cylinder, consider that a standard locking cylinder with a bore of 84 mm can withstand static forces ranging to 700,000 newtons (N). This would require a bore size of 200 mm with a standard cylinder and a high-quality check valve that withstands 450 bars. A self-locking cylinder in this scenario will only work properly if the rod reaches its outermost position because only then can the segmented ring engage properly in its seat. It also should perform its return stroke entirely to operate efficiently.

In some molds, the core must touch other parts of the cavity wall without any clearance. When this is necessary, generally, a flange on the core leans on a counterpart in the mold with no clearance, in order to avoid flash. Flash is excess material on solidified plastic parts. It can occur when the injection pressure separates the surface of the core and the counter-surface that it is touching. Even a tiny gap can cause flashing. Typically, flash can be avoided either by reducing injection pressure or increasing clamping force.

Preload can help maintain contact between surfaces and avoid flash. Since a self-locking cylinder must reach its full stroke in order to lock into position, preload may be required here as well. To help illustrate preload, consider a tie-rod cylinder. When it is assembled, tie rods are tightened (elongated), and the tube is compressed (shrinks). When oil pressure is applied, additional elongation and stress in the tie rod is negligible, thanks to the recovery in compression of the tube. In practice, oil pressure is supported by transferring the force from the tube (compression) to the rod (elongation). The system is very stiff, and fatigue stress is greatly reduced.

Something similar occurs in preloaded self-locking cylinders. The rod, when fully out, presses against a stop and is compressed. The result is a force between the two closing surfaces of the core. This force prevents plastic material from seeping in after injection pressure is applied, so flash is avoided.

To obtain the desired preload in a self-locking cylinder, shims can be mounted between the cylinder and the mounting surface. Because the measurements are very precise (0.01 mm), it could take several attempts to get the correct amount of preload. This entails assembling the mold, testing, disassembling the mold, adding or removing shims, and reassembling.

Another option for preloading a self-locking cylinder is a threaded flange. The flange is mounted on the mold, and the locking cylinder is then threaded onto the flange. A setscrew maintains the position of the cylinder on the flange. Preload can then be adjusted by releasing the setscrew and turning the cylinder in small increments to move it forward or backward. Tighten the setscrew, and you are ready to test again.

Understanding the technology behind self-locking hydraulic cylinders, and the concept and impact of preload will help moldmakers make educated decisions to solve the challenges associated with sliding cores.

Related Content

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read MorePlastic Prototypes Using Silicone Rubber Molds

How-to, step-by-step instructions that take you from making the master pattern to making the mold and casting the plastic parts.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreTreatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.png;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)