Seeing Is Believing

Design-of-Experiments (DOE) is a statistical tool that enables you to see the effect of some intervention on the quality of the part. Listen in to next Tuesday's webinar on using DOE with Moldflow® to see how it all works and what it all means.

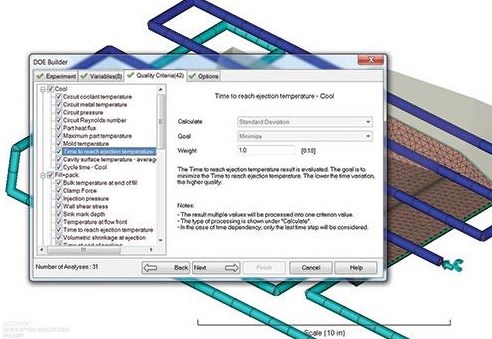

Design-of-Experiments (DOE) enables you to see the effect of some intervention on the quality of the part. Listen in to next Tuesday's webinar at 10am, presented by Autodesk, to see the effects of using DOE with Moldflow®. DOE is a statistical engineering method that determines which variables have the greatest effect on final part quality and which have the least effect. Users input ranges of process or geometry variables, and DOE analysis shows the sensitivity of each variable and ultimately what set of conditions produce the shortest cycle time. When used early in design stages, DOE analyses can help improve part designs by guiding decisions related to the plethora of available factor combinations. This type of analysis can also be used to hone mold design details for efficiency.

Click here to learn more and register.

.jpg;maxWidth=300;quality=90)