Rapid Prototyping’s Role in Customized Manufacturing

A look at the future potential of additive manufacturing technologies you’ve come to know, as they enter the world of customizable products.

The trend is people are no longer only satisfied with mass manufactured goods, they want personalized, customized things. When you look around on the Internet or in the shops you see it everywhere. You can customize your shoes at NikeId or upload your own pictures to make personalized M&Ms. At IKEA you can even customize and order your own kitchen built to specification. When we think about it, it should not be surprising that this trend is developing.

Since the early 1900s we have become addicted to mass production and mass produced goods, but why? Mass production was the way to make consumables at prices acceptable to many people. Take the model T Ford, for example. Ford did not make it only in black because it was what everybody wanted, but because making it in one color enabled mass production. Mass production meant less production cost, thus making it affordable to a much bigger audience.

Of course current technologies allow for more than one color car and automakers are good at offering us plenty of choices when we want to buy a new model, but cars are not completely built to customer specifications yet. However, Ferrari seems to be getting very close with the Special Projects unique cars at a very handsome price tag.

The reason why custom items are so expensive is that existing manufacturing techniques are geared toward making the same items over and over again. In addition to efficient production, we have to consider specification. How will consumers tell manufacturers exactly what they want? How can we produce unique items at an acceptable cost? How can customers tell manufacturers what they want in an exact, effective and easy way?

The need is to find manufacturing technologies that are very good at making unique quality items reliably and cost effectively, and for a user-interface enabling customers to effectively articulate what they want in an easy way.

Technology’s Role

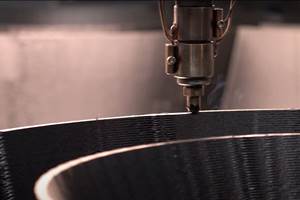

Technology that is beginning to be known by the general public—3-D printing, direct digital manufacturing or additive manufacturing—seems ideally suited to make unique production very cost effective.

Based on digital input these machines can produce completely ready objects in a fully autonomous way. The parts made do not necessarily need assembly, just cleaning; and only if required, post production like painting. When making unique items, there are no long preconfiguration setup times; just upload the digital description of the model and the machine builds it.

Using technologies like selective laser sintering, it is possible to produce several items at the same time—sometimes more than a hundred items. People are making products for hobbies like model trains, remote-controlled aircrafts, 3-D puzzles, gadgets, home decoration items and jewelry.

Challenges

There are many limitations to the application of this technology. Today materials are limited to plastics and metals. However, mixing two materials is now possible, although it is the exception at the moment. It is predicted that these technologies will be accessible to the general public at an accelerated pace. In laboratories, printing of ceramics and glass has been tested and will be made accessible in the near future.

Describing in detail what the consumer or user wants is the real challenge. In the age of mass production, consumers are able to choose in stores or from catalogs a product that is closest to what they want. In the case of personalized production, everything is possible, so consumers need to share precisely what they want.

To keep it efficient, they need to share this information in such a way that additive manufacturing machines can make it. Therefore, the real key to unlock personalized production through additive manufacturing is content.

AM machines require detailed files with mesh and texture data that is typically produced with CAD software, which is not expected for everybody to learn, so developing easy-to-use tools enabling consumers to explain what they want is necessary.

Some existing Web tools are out there for the user. Since most consumers want to be inspired or assisted, it is adaptive or parametric designs that will be the most popular. In parametric designs, the user can adapt an already existing design within certain pre-set boundaries. These boundaries ensure that the user can customize and personalize, but still get a beautiful, usable item.The exceptional benefit is that with these new production technologies, it is the customer who chooses.

In the Near Future

It is starting to happen. Companies are offering direct access to not only production capability, but also to designs that can be ordered or adapted then ordered. This is directly enabling the consumer of the 21st century for the first time to order items/goods really needed, and not items that are pre-designed, pre-produced and then pre-shipped to stores forcing them to compromise and buy items that are close to, but not exactly what they need.

The possiblities of these new services are only starting to be explored. If this is not an exciting new chapter to the history of additive manufacturing I do not know what is!

Related Content

Large Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

Read MoreHow to Prepare for the Rise of AM in Moldmaking

Mold builders should consider investing in three key areas to take advantage of the opportunities 3D printing presents.

Read MoreVariable Density-Coated Tool Steel for High-Wear Molds

A mold builder can have an abundance of venting and fully dense solid areas in steel by using variable density sintering to eliminate gas trap defects in high-wear molds.

Read MoreVIDEO: What Does Integrated Predictive Modeling Mean to Moldmaking

Although conformal cooling is not a new concept, new technologies have made it a very hot topic, including predictive engineering models and 3D printing. Learn about a new conformal cooling process and algorithm and what it reveals about hot spots and conformal cooling design.

Read MoreRead Next

Low-Volume Layered Manufacturing: Parts without Limits

An alternative design and manufacturing method that uses a layer-by-layer process, virtually eliminating part design constraints that exist with traditional manufacturing processes, such as CNC machining and injection molding.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)