Putting the Wow Factor into a Moldmaking Career Display

The Chicago Chapter of the American Mold Builders Association added more visually-enticing items that teach about, and promote, moldmaking as a high-tech career option.

Last Friday, I blogged about an email conversation that occurred between a few members of the American Mold Builders Association Chicago Chapter Education Committee. The crux of the blog was to point out how, even via email, a group of motivated individuals can help spearhead an array of ideas for advancing initiatives to engage young students and introduce them to the world of moldmaking. Today, I’m blogging to share an idea that became reality for the chapter.

Some months ago, members of the education committee met to review recent and upcoming trade events and career fairs and hit upon the idea of finding something cool for the booth that would add that “wow factor” and show how high-tech and viable a moldmaking or related career can be. At first, someone suggested purchasing a tabletop 3D printer, which would be cool but many schools are investing in them and so students are already familiar with it. Another idea was to buy a tabletop CNC milling machine. Aha! A key piece of equipment in the moldmaking process and cool to watch. Committee member Greg Osborne of Synventive Molding Solutions volunteered to research some options, and last week the Chicago Chapter gathered to see a demonstration of its new Roland DGA Corp. monoFab SRM-20 Desktop Milling Machine.

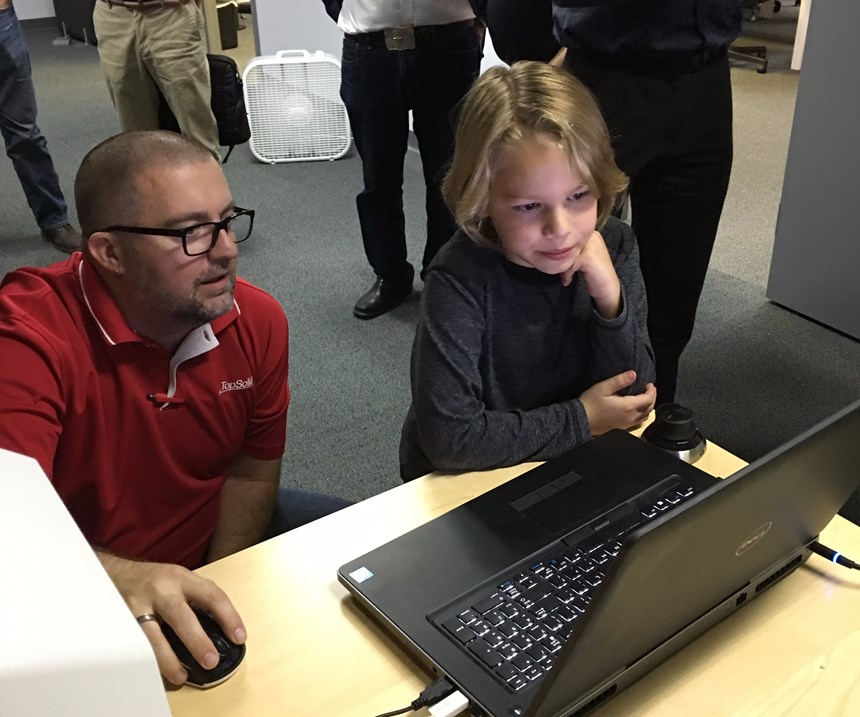

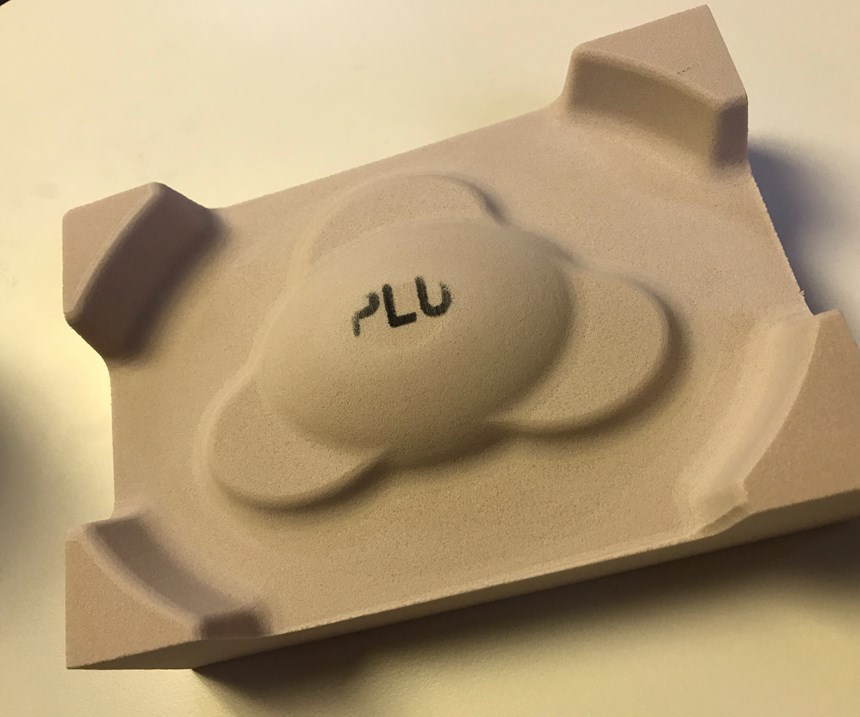

The group gathered at TopSolid / Missler Software, Inc. Lombard, Illinois, office to watch the SRM-20 machine its first part, which looks like a prototype for a fidget spinner. The part was designed and programmed by Missler’s Bill Genc using TopSolid design software, which was donated along with a laptop by Missler. It must also be noted that the purchase of the SRM-20 was made possible by the generosity of the AMBA’s Mold Maker of the Year, Joe Genc of Graphic Tool Corp As the organization’s national honoree, Joe was presented with a check for $5,000 by Progressive Components. The funds were earmarked for donation in Joe’s name to a trade-related program of his choosing.

In all the excitement that evening, no one missed a clear sign that the SRM-20 was just what was needed for a wow factor in the booth. Progressive’s Lorena Fisher is a member of the AMBA Chicago Chapter’s education committee and it board of directors. She happened to bring her seven-year-old son Leo along to the meeting. The young boy was not only very well behaved during the meeting, he was captivated by the SRM-20 as it milled the demo part. Seven years old… and he was also interested in learning how the design was created and set up for production. The images above tell the story.

Wow factor indeed.