Part One of Three: Detecting, Repairing and Preventing Water Leaks

How to improve your leak detection methods.

It was a devastating incident. The badly needed hot runner mold was in the press and being prepped for its maiden run since a complete hot manifold rebuild (due to an untimely encapsulation). The mold had been leveled, clamped, plumbed, wired, unstrapped and opened. All that was left was to turn on the water and fire up the heaters. The busy mold setup guy decided to forgo the standard air pressure check of the water circuits assuming either the manifold vendor or toolroom had already performed it. My … what 10 minutes can cost.

He turned on the water valves and stood to receive a face full of … bad news. Water shot out from all 12 plug locations on the “A” side cavity plate and hosed down everything within 15 feet. He heroically ignored the nasty tasting glycol shower and frantically shut off the valves, but the damage had been done. All 16 probe heaters, including the manifold cal-rod heaters and one exasperated mold setup guy had been thoroughly drenched.

The next couple of days were spent engaged in some good old-fashioned finger pointing while attempting to dry out the heaters. But open shorts were obvious throughout the mold and the decision was made to send it back to the vendor for another expensive rebuild. How did this happen? Could this have been prevented? (Read The Final Check from the February 2005 issue for tips on avoiding this type of catastrophe at your company).

Water leaks cost companies thousands of dollars in labor hours and lost product, but when your business is molding, water leaks go with the territory. Most root causes are simply oversights, failing to exercise caution during mold assembly and installation and a lack of proper final check procedures. However, much can be done to more accurately locate, repair and prevent this costly downtime occurrence.

In plants where downtime is categorized and tracked, internal and external water leaks have been shown to account for 45 percent of all maintenance initiated downtime. Eighty percent of those failures are due to missing or improper o-ring/tooling installation on the bench or mold set practices at the press. The other 20 percent is split between cracked tooling or worn/pitted o-ring glands in plates and tooling and bad design.

Troubleshooting leaking molds is akin to troubleshooting leaking roofs. The location of the drip is not necessarily the location of the leak. This article will deal with improving detection methods.

In-Press Detection

The worst thing to do (but usually the first) is to immediately pull the mold and send it to the shop to have a leak repaired. Many times tooling and o-rings leak only under clamp or injection pressure and this cannot be replicated on the bench. Other times, mold setups will notice water dripping from the bottom of a mold and pull it without first determining which half, quadrant or even the general location the leak is coming from. This greatly lengthens the time it takes the shop to troubleshoot the leak, and if the leak happens to originate externally from a loose or improperly installed pipe or snap fitting, this discovery will further aggravate a typically delicate relationship between the tooling and process side of running molds.

When the inevitable water leak occurs, there are several steps that should occur in order to help isolate the leak and determine exactly where it is coming from before the decision is made to send it to the shop.

Check Out the History

Before you even walk out to the press, take a quick look (a quick look should require less than five minutes to answer the following three questions) at the mold history to determine:

- If the mold has a history of leaking and where.

- Was the mold recently worked on and were any o-rings changed or disturbed (last cleaning level performed)?

- Did the mold receive a proper final check before being sent to production? If it didn’t leak on the bench, then it could be clamp or injection pressure-related and will need to be run or dry cycled to make it leak.

Having this knowledge will clarify puzzling visual clues you might see at the press.

Dry It Out

- Verify that all water lines on the suspect side of the mold are shut-off.

- Unless the location of leak is obvious, dry the mold/tooling using air pressure and towels. If the mold faces/cavities are drenched, experienced techs know that blowing air across the face of tooling is a preferred method and will actually pull water out of cavities, acting as a venturi. Blowing directly against the face will force water deep into tooling clearance and recesses, only to migrate out or cause other issues later.

- Alcohol, and in extreme cases, acetone, is sometimes used as a drying agent to eliminate the water quicker. I’ve tried this method, but I’ve never had consistent results nor been satisfied that it wasn’t (dangerous) causing accelerated corrosion/wear issues within the mold tooling so I won’t endorse the technique, but I know it is standard practice with some molders. I am just not in favor of forcing any type of spray or liquid into cavity tooling recesses and clearances.

- After the initial blow-dry is complete, actuate ejector stripper plates to extend tooling and plates to get better internal access.

- Be sure to thoroughly blow out all external water fitting counter-bores and other cracks, slots and holes where water can lie and leach.

Most times you can now reopen the valves and watch for the leak, or drip to reappear. When a static leak occurs around an A or B side cavity, where the o-rings seal against a bore I.D, the water leak can drip down the face, making it easy to see, so the whole mold, or just the affected cavity/plate if possible, can be removed, and taken to the toolroom for repair.

If the o-ring leaks at the back of the cavity, gravity carries the water to the bottom of a plate, so determining the exact location is much more difficult.

Also difficult are internal dynamic (rotating shafts) leaks that cause water to gravitate one or two plates away from the source of the leak. The object now becomes to find the circuit that is feeding the leak. There are two methods for this:

1. One Circuit at a Time

Redry the mold and only turn on one circuit at a time, allowing ample time for water to reappear at the bottom of the plate. If you are using jumpers (then shame on you) they

must be removed and each circuit hooked up individually. By locating the circuit that is feeding the leak, you can narrow down the potential causes significantly, which is critical with multi-cavity molds.

Another method is using air pressure to test the individual circuits. Simply blow out the waterlines and plumb an air fitting and pressure gauge with the snap-on water fitting and pressurize the circuit with standard line pressure (usually about 90 psi). The severity of the leak will determine how quickly you observe a pressure loss.

Once you locate the guilty circuit, the next step is to try and determine the com-ponent within this circuit that is leaking.

2. Using Dye

One method that I’ve used with moderate success at the bench and the press is to utilize food coloring to identify where the leak is coming from. Using several colors (red, blue, yellow and green) in different circuits can speed up the process of determining which circuit, and sometimes which component, is leaking. Be advised that there is some preparation to make this procedure accurate. Don’t make the mistake of simply putting a few drops of the dye directly into the “In” water-line, shutting off the outboard waterline and waiting for the magic to happen. It won’t. An adequate concentration of dye must be distributed throughout the mold circuit, before you pressurize it.

The best method is to have on hand several clear waterlines equipped with the appropriate fittings that will allow you to install these coming right off the mold and into outboard or return lines.

Depressurize the system, leave the water-lines full and simply follow these steps:

- Unhook the inboard waterline of the circuits you want to test. Only remove enough water (soak out with a towel) from the line to add the dye.

- Pour the dye (I use a one-ounce bottle; might be concentration overkill, but I want to be sure I have enough and the stuff is cheap) into the waterline hose or, if you use snap (quick-disconnect) fittings, pour directly into the mold’s pipe fitting and reconnect the hose.

- Be sure the outboard line is shut-off and turn the water on to pressurize the circuit.

- Slowly open the outboard valve until you see the dyed water appear, then close it. This is the critical part. Wait too long and the dye will simply flow through the circuit. Shut it off too soon and there might not be enough dye left at the point of the leak to accurately verify. It will darken quickly, so be ready.

At this point you can now dry cycle the mold for a time, or even shoot a couple of shots if you suspect the leak is injection pressure related. As a bonus, depending upon the part produced, the dye can even show up on the part, showing precisely where the tooling is cracked without further wasting bench time.

If nothing can be done at the press, open the valves until the lines run clean then blow air through all of the mold circuits to remove as much water as possible. Do this again when the mold gets into the shop. This will prevent the water from pouring from between plates when the mold gets disassembled, which will dilute the dye trail.

On the Bench

Most water leaks are detected on the bench through the typical procedure of running water through the mold circuit then pressurizing with 90 psi of air. With the mold disassembled, cores, cavities, sleeves and other components can be better seen while still retained in the plates, allowing the tech to jiggle, tap or otherwise side-load tooling looking for cracks, or bad o-ring seal points.

Occasionally, it is necessary to remove the retaining plate to expose the backs of tooling for a clearer view. A steel or aluminum bar of sufficient size (at least 2" x 2" if clamped across a line of eight cavities totaling approximately three feet) can be used to hold one circuit (line) of tooling in the plate allowing moderate (under 75 psi) pressurization. The danger is using a bar stock too small for the o-ring diameter and jacking up the pressures too high on tooling where the back o-ring is larger than front. I have seen one-inch steel bars bend far enough (1/4") under pressure to let the back o-ring escape its bore, hosing down everyone around before the valve can be turned off. Also, if the clamps used don’t squarely engage the bar stock, they can slip off under pressure and all eight cavities will shoot backwards … not fun.

Editor’s Note: You can read the next part in the series by clicking here.

Related Content

Most-Viewed Content of 2022

The most popular MoldMaking Technology content according to analytics reports over the past 12 months.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreWhat You Should Know About Injection Mold Safety Straps

Every mold should have one in order to be safe and OSHA compliant.

Read MorePortable Low-Heat, Non-Arcing Resistance Welder for Mold Repair

Rocklin’s user-friendly MoldMender Micro Welder delivers simple and cost-effective localized repair in-house with precision and versatility, enhancing mold and die durability and reducing disassembly and downtime.

Read MoreRead Next

Part Three of a Three-Part Series Detecting, Repairing and Preventing Water Leaks

Clear cut methods that prove effective on troublesome installations.

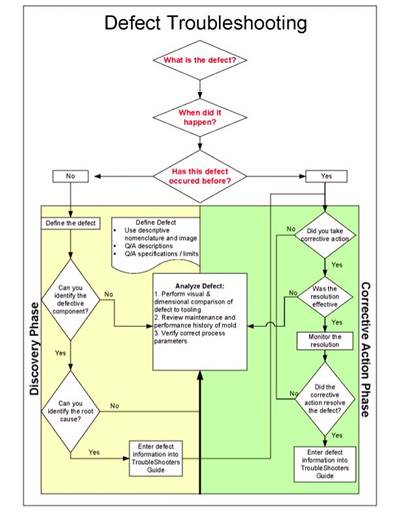

Read MoreAcross the Bench: Troubleshooting Defects: Part I

Using analytical skills based on historical mold performance and maintenance requirements, combined with mold and part defect data determines probable causes and corrective actions.

Read More

.jpg;maxWidth=300;quality=90)