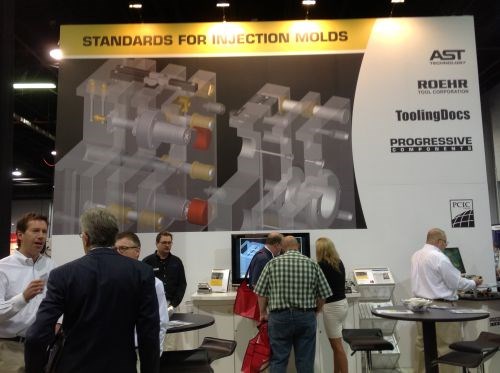

One-Stop Shopping on the Show Floor

At amerimold this week attendees were able to see firsthand everything needed to design, build and repair molds—from art to part!

Here is just a sampling of some of the technology seen at amerimold 2013:

For RP, Stratasys showed parts the company produced with its 3D printers, so mold engineers can create and customize molds for short runs—saving time and money.

On the software end, CGS North America demonstrated the latest version of its Elite CAD/CAM Software CAM-TOOL Version 9.1. Attendees saw how this program has the ability to machine to machine a mold or die with minimal to no polishing.

Diehl Steel highlighted its CPM Powder Metal Tool Steel. Company representatives explained how the CPM process produces more highly alloyed grades of steel which cannot be produced by conventional steelmaking, which results in a very fine, more uniform carbide distribution and imparts improved toughness and grindability, dimensional stability, as well as outstanding hardness, wear resistance and heat resistance.

Progressive Components’ booth showcased its wide variety of components—including its Z-Series alignment locks, lifters, CamActions and parting line sequence control devices.

The Hi-QuadF™ line of high-feed cutters from Ingersoll Cutting Tools was front and center, including models with a 13-mm and a 19-mm IC quad-style insert, which provides four cutting edges with a choice of eight different cutting edge geometries.

GF AgieCharmilles showed off its Mikron HSM 200U LP (linear performance) milling machine and its Form 20 sinker EDM. The machine provides 5-axis simultaneous milling to the machining of small, highly complex components with linear motor technology; and the sinker EDM has the recently developed AC Form HMI (human machine interface) CNC that centers on user friendliness and intuitiveness to significantly shorten the learning curve for beginner EDM operators.

A Multi-Channel Optical Touch Probe System was the focus of the Marposs booth. The Mida VOS optical touch probe system, designed for use on large three- and five-axis machining centers, has a receiver with integrated interface and a transmitter unit that is compatible with the full range of Mida touch-trigger probes. It is available in both a compact and modular version for application flexibility.

Boride Engineered Abrasives displayed the latest addition in its moldstone lineup—the Golden Star. It has a medium hardness with a fast breakdown, which company representatives explained offers quick material removal while contouring quickly and leaving a silky smooth finish.Click here to see more of the products and equipment seen at amerimold this week.

Click here to see more of the products and equipment seen at amerimold this week.

_300x250 4.png;maxWidth=300;quality=90)