On the Cutting Edge: The Case for High-Speed Hard Machining

By now, the terms "high-speed machining" and "hard milling" have become familiar - at least in the moldmaking universe

By now, the terms "high-speed machining" and "hard milling" have become familiar - at least in the moldmaking universe. Equally well known are the benefits of these technologies when applied to moldmaking; chief among them being timesavings, shorter leadtimes and enhanced process control. The path to achieve these benefits, however, remains somewhat obscured.

These separate machining technologies, due to their symbiotic nature and mutual applicability to moldmaking, have become almost synonymous in today's lexicon. But, as these terms suggest, the principle of high-speed milling is primarily concerned with speed, and has been defined as above 200 inches per minute (5.08m/min.). Conversely, the principle of hard milling is only concerned with material hardness - 48Rc. and above is a commonly mentioned threshold. While softer materials, such as aluminum, can be machined successfully utilizing the techniques of high-speed machining, this discussion centers on machining hard materials.

Featured Content

From the moldmaker's perspective, knowing that hardness means greater than 48Rc. and that high speed means greater than 200 inches per minute does not provide the information necessary to perform high-speed hard machining operations in producing cavity and core blocks. These stringent and scientific definitions may be misleading and present a restrictive and inaccessible view of high-speed machining. Perhaps a better view of high-speed machining and hard milling is as a combination of techniques that form a comprehensive process called High-Speed Hard Machining (HSHM).

HSHM for the Real World

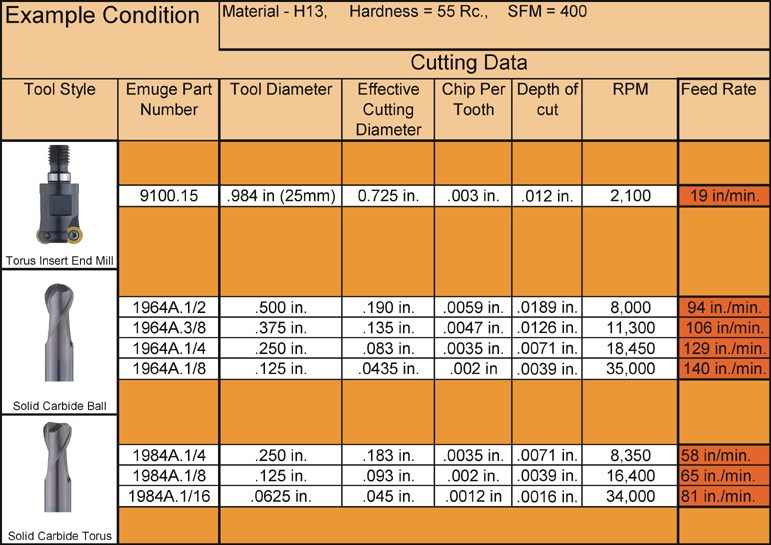

The 200-inch-per-minute definition is misleading because it does not take tool diameter into consideration. HSHM techniques can be utilized with tools regardless of diameter. For example, a five-inch diameter indexable insert end mill, with eight, 1/2 inch diameter inserts, machining H-13 at 55Rc., at a cutting depth of .016 inches, will require a feedrate of only eight inches per minute and a spindle speed of 350 rpm. Although this feedrate is drastically below the 200 inches per minute threshold, this tool can be effectively incorporated into the HSHM process. Figure 1 details cutting data for a range of tools typical to a real world HSHM program. Note that none of the feedrates exceed 200 inches per minute.

In the real world, 40,000-rpm spindles are more the exception than the rule. More common are 10,000- or 15,000-rpm spindles. It is therefore important to note that feedrates can be adjusted down in relation to a maximum spindle speed limitation such as 15,000 rpm, as long as the feedrate is adjusted accordingly. Using the example of the 1/8 ball end mill from Figure 1, rpm = 35,000.

The feedrate of 140 inches per minute has been determined by the following formula:

Vf = fz x Z x n

Where:

- Vf = feedrate

- fz = chip per tooth

- Z = Number of flutes

- n = rpm

Inserting the values from this example:

- Vf = .002 x 2 x 35,000

- Vf = 140 in./min.

In the case of a 15,000 rpm maximum spindle speed restriction, the same formula is used, except n = 15,000, resulting in the following changes:

- Vf = .002 x 2 x 15,000

- Vf = 60 in./min.

This solution allows for the implementation of HSHM techniques under real world conditions. In this example, it will take more than twice as long to complete the same tool paths, but only for the smallest diameter tools in the program's range. The remaining tools in the HSHM program will run at their maximum feedrates, which will minimize overall time loss. Although the speed and feed have been reduced, the most important of these parameters have been maintained - fz (chip per tooth) and ap (depth of cut), which will promote reasonable tool life.

The HSHM Triad

A successful HSHM process must incorporate three independent elements: the machine tool, the cutting tools and CAD/CAM software. To substantiate this point, witness the attention the moldmaking industry has received from these sectors in the last few years. Almost all of the major machine tool builders, cutting tool manufacturers and CAD/CAM providers offer products directed exclusively to moldmakers.

Each of these elements is equally essential for successful HSHM, and each is dependent on the performance of the others in order to perform to full potential. An appropriate analogy could be made to an equilateral triangle. Picture each of these elements as one side of the triangle. Each side must be maintained for the shape to remain an equilateral triangle, just as each element must be maintained if successful HSHM is to be achieved. This is the HSHM Triad (see Figure 2).

Of these elements, cutting tools are the most dependent on the performance of the other elements. The argument can be made that the purpose of the high-speed milling machine, as well as the CAD/CAM software, is to present the cutting tool to the work piece under optimum conditions. Cutting tools specifically designed for HSHM operate within a very narrow band of parameters, which must be maintained throughout the machining process or tool life will be adversely affected.

Some of the most important factors for each of the HSHM elements as they relate to tool life preservation include machine tools, software and cutting tools.

Machine Tools

The most important feature of high-speed machining is not, as it may seem, spindle speed, but rather the machine's rigidity. Machine rigidity is important because the cutting tool must be free from vibration, which at high rpm will cause the cutting edge of the tool to crack, fracture and break down prematurely.

Another important feature is the machine tool control's ability to receive and process the machine code in real time. The programs generated by the CAD/CAM contain a massive number of lines, and the machine must be able to maintain cutting parameters without running out of data to present to the cutting tool. This is a condition called "data starvation" and can actually cause the program to stop or stall - a condition most detrimental to tool life. This however, is probably not as much of a concern as it once was, considering today's advancements in machine technology.

Software

Specially designed CAD/CAM software programs have the ability to process a CAD program and generate millions of lines of machine code. Also, the program knows where it has been and where it is going, and can therefore calculate proper feedrates, spindle speeds and cutting depths - all in order to preserve the tool's optimum cutting characteristics.

The software also includes verification and optimization routines, either as an additional package or fully integrated into the CAM software. The optimization feature takes the raw M code and streamlines all feeds, entrance and exit angles and maximizes rapid feed rates. This becomes crucial for tool life and gaining maximum timesaving benefits from the HSHM method. The verification software allows the job to be run in a virtual environment - errant toolpaths and rapid moves are removed, thus eliminating crash danger while increasing operator confidence. Operator confidence is important because it will help to eliminate the operator's inclination to manually override feeds and speeds, which would otherwise increase machine time.

Cutting Tools

Solid carbide end mills and indexable tools made of sub-micrograin carbides are preferred for HSHM. Solid carbide tools utilize progressive cutting geometries (neutral rake angles) and two-flute designs, which are preferable for chip evacuation and heat dissipation. Indexable tools utilize round insert geometry - the shape that leaves the least residual material for subsequent operations such as milling or bench work.

Both types of tooling utilize TiAlN coatings, which have exceptional wear and heat characteristics. The use of these coated carbides enables dry cutting, the benefits of which include elimination of coolant, all related maintenance, and treatment and hazardous waste disposal, which studies have shown can account for more than 15 percent of total production costs. An additional gain goes to environmental concerns.

Another important feature of cutting tools is the clamping method. Heat shrink tooling provides the best concentricity and the highest clamping forces as well as quick tool changes and repeatability. Heat shrink holders are available for all taper styles; however, HSK hollow taper tool holders are rated highest for balance at high rpm. In addition, because of their design and lack of a full taper, there is the danger of the combination of machining force and centrifugal force jamming the holder into the spindle - especially for standard ISO and CAT taper holders.

HSHM in Production

Probably the biggest misconception is that "high-speed machining" translates directly to "faster machining." In many applications it may be the case that the same volume of material can be removed through conventional methods in a shorter period of time.

It is not until the Triad of elements is introduced into mold production that the full benefits of HSHM are realized. It is the resulting condition of the machining process that dictates the time saved on subsequent operations. In the case of HSHM, the block is at, or near, finished geometry. Depending on final part geometry, the need for EDM, as well as hand polishing and blending operations, are either greatly reduced or eliminated entirely.

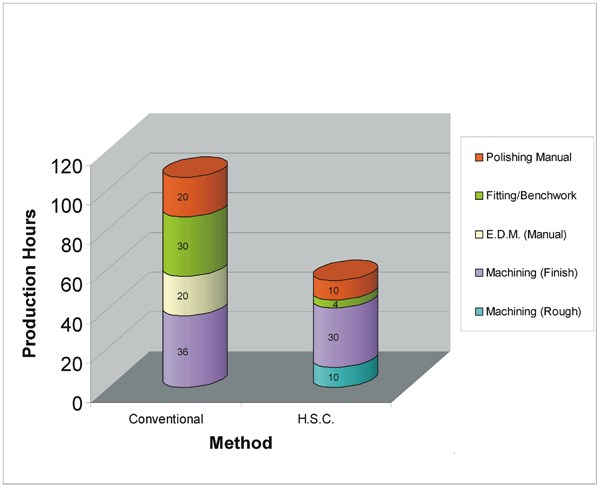

Figure 3 details an example of a cavity and core manufactured both in the conventional and HSHM methods. In the conventional process, the actual machining time is 30 hours, while in the HSHM process the total machine time, including roughing and finishing, is 36 hours. It is the remaining operations where the time is saved, as this chart demonstrates. The total time saved in this particular example is almost 50 percent - from a total of 106 hours in the conventional process down to 54 hours using HSHM. In this example, due to the accuracy of the HSHM process, the predominance of timesaving occurs in the polishing and fitting and EDM operations.

The Future of HSHM

There has been debate over the future of HSHM and whether it is a technology that is here to stay. It seems obvious that in any industry, if a new technique or change in the process is developed that can save 30 to 50 percent of the time consumed in the original process, then the acceptance of this new method is inevitable.

In the future, the technologies relating to HSHM will continue to develop and evolve. If the past is any example, the new technologies of today will become more affordable and accessible due to the realization of technological advances and economies of scale. Machines with spindle speeds in the 30,000 to 40,000 rpm range will become more common, which will contribute to the overall acceptance of HSHM. New and evolving technologies will lead to further developments in machine design, such as composite machine bases and other as yet unrealized innovations.

From the cutting tool side, the increasing demands for longer tool life and higher performance will likely bring about new coating materials as well as advancements in carbide manufacturing.

Currently, there is a tide of change in moldmaking, and it would seem that in such a competitive industry, those who will adopt new technologies will be left standing, while those who hesitate will be left behind.