Name Change Reflects Diverse Offering

The name GF AgieCharmilles may be best known for its EDMs, but the division of global industrial firm Georg Fischer AG has far more to offer. To reflect growth in other areas, the entity is now called GF Machining Solutions.

When you hear the name GF AgieCharmilles, what comes to mind?

Glynn Fletcher, president of the entity’s American arm, says the answer is likely EDM equipment. Yet recent years have seen significant growth in its other brands: System 3R workholding products, Step-Tec spindles, and, particularly, Mikron high speed milling machines. This growth is one reason why GF AgieCharmilles is now known as GF Machining Solutions, effective January 1. “EDM represents about 1/3 of our overall business, so it’s important to communicate our broader capability,” Fletcher says.

That’s not the only reason for the change. GF stands for Georg Fischer AG, the Swiss parent company of GF Machining Solutions. This large firm also controls two other divisions: GF Piping Systems and GF Automotive, both of which are larger than the machining arm and are better known in Europe than here in the states. Compared to the old moniker, “GF Machining Solutions” underscores the fact that this is just one of three divisions of a unified company that offers not just machinery, but a range of services for a range of markets and applications, Fletcher says.

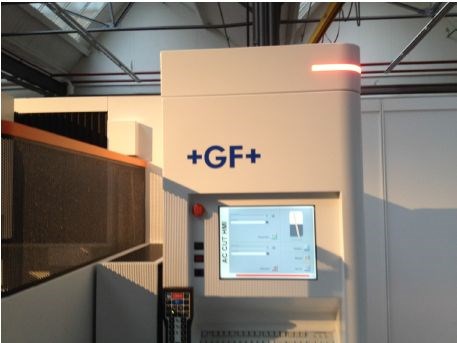

The machines themselves will have a slightly new look, with the “GF” logo displayed prominently over the individual brands (AgieCharmilles for EDM equipment, Mikron for milling equipment, and so forth). Likewise, the company will update the design of its Web site, sales literature and other communications. However, Fletcher emphasizes that the change will be transparent for customers, who can interact with company in the same way and will continue to see any agreements fully honored.

Related Content

-

U.S. Economic Fundamentals Impacting Moldmaking

The economy continues to downshift, capping growth in moldmaking.

-

Exploring ISO 9000 - Part 16 Control of Quality Records

A Series of International Standards for Quality Management and Quality Assurance. We begin 2022 with a review of Clause 4.16 Control of Quality Records.

-

MMT Chats: Marketing’s Impact on Mold Manufacturing

Kelly Kasner, Director of Sales and Marketing for Michiana Global Mold (MGM) talks about the benefits her marketing and advertising, MGM’s China partnership and the next-generation skills gap. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

.jpg;maxWidth=300;quality=90)