Moldmaking Index Remains in Lower Range

The Moldmaking Index was led higher by supplier deliveries, new orders, production and employment.

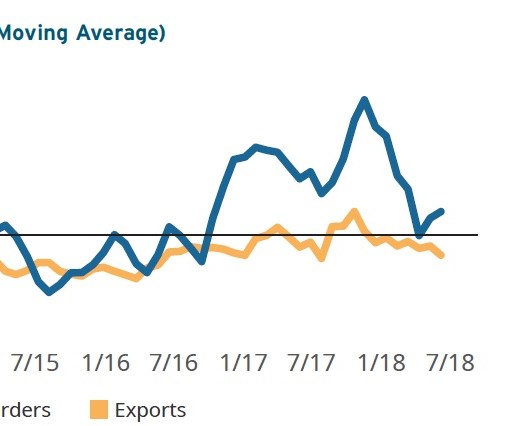

Registering 52.9 for October, the Gardner Business Index (GBI): Moldmaking moved slightly

lower as backlogs and exports both significantly weighted on the Moldmaking Index’s latest

performance. Compared to the same month one year ago, the Moldmaking Index is down

8.2 percent. Gardner Intelligence’s review of the underlying data for the month reveals that

the Moldmaking Index was lifted higher by supplier deliveries, new orders, production and

employment. The averages-based index was pulled lower by contracting backlogs and exports.

The latest round of U.S. and Chinese tariffs, which have been implemented in escalating

fashion, took effect in late September. The total effect from the many rounds of tariffs that

have taken place under both governments have significantly impacted the cost of aluminum,

steel and mold products. In addition, the rising value of the U.S. dollar against the Chinese

Yuan has put U.S. manufacturers at an additional disadvantage when competing abroad. Under the current conditions, moldmakers will have to master their supply chains and seek to replace lost opportunities abroad with new domestic opportunities.

For More Information

Stay ahead of the curve with Gardner Intelligence.

About the Author

Related Content

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

-

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

-

Mold Builder Uses Counter-Intuitive Approach for Mold Challenges

Matrix Tool Inc. answers customers’ hard questions with creative solutions for cavity spacing, tool sizing, runner layout and melt delivery that reveal the benefits of running in a smaller press size at lower cavitation but higher yield.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)